Commander SE Advanced User Guide 181

Issue Number: 4

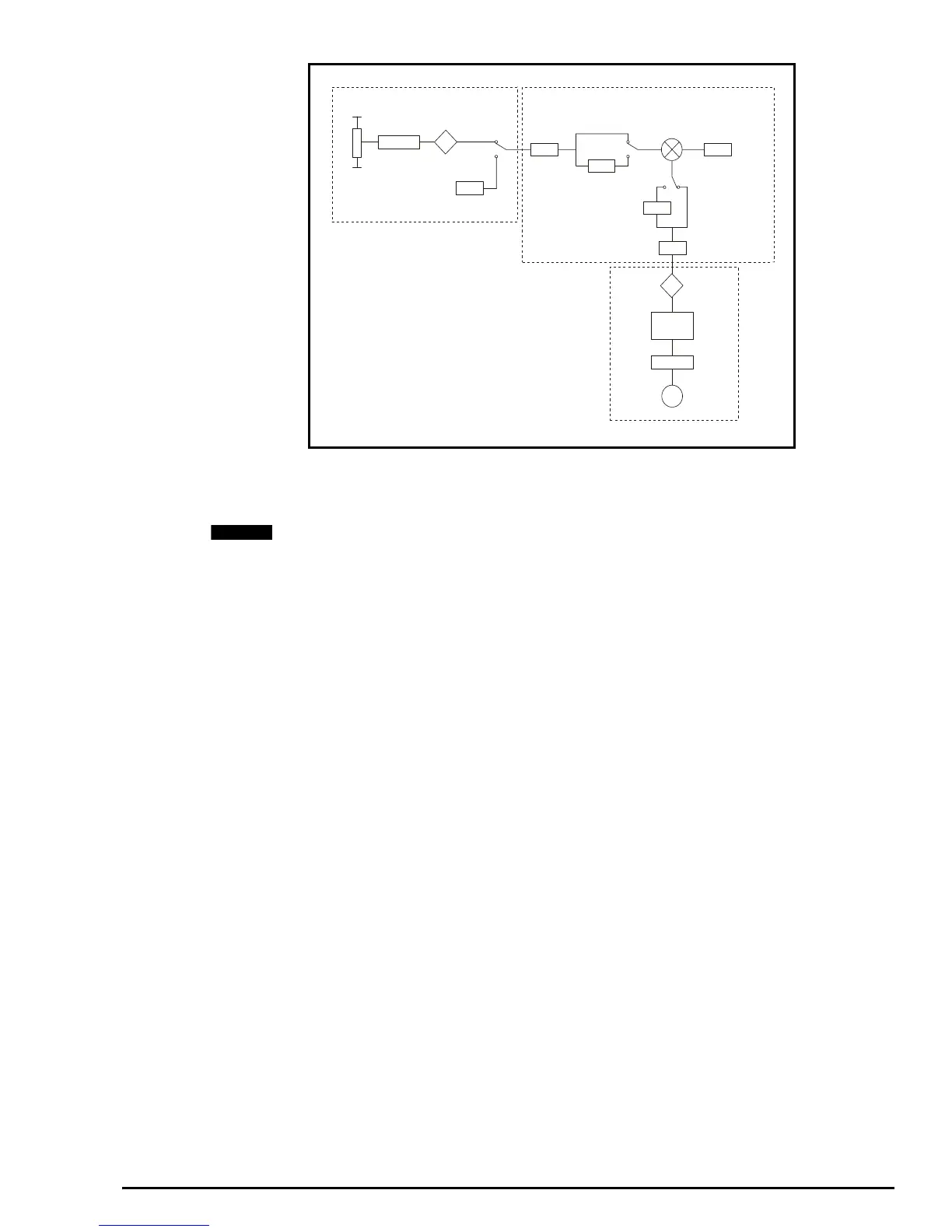

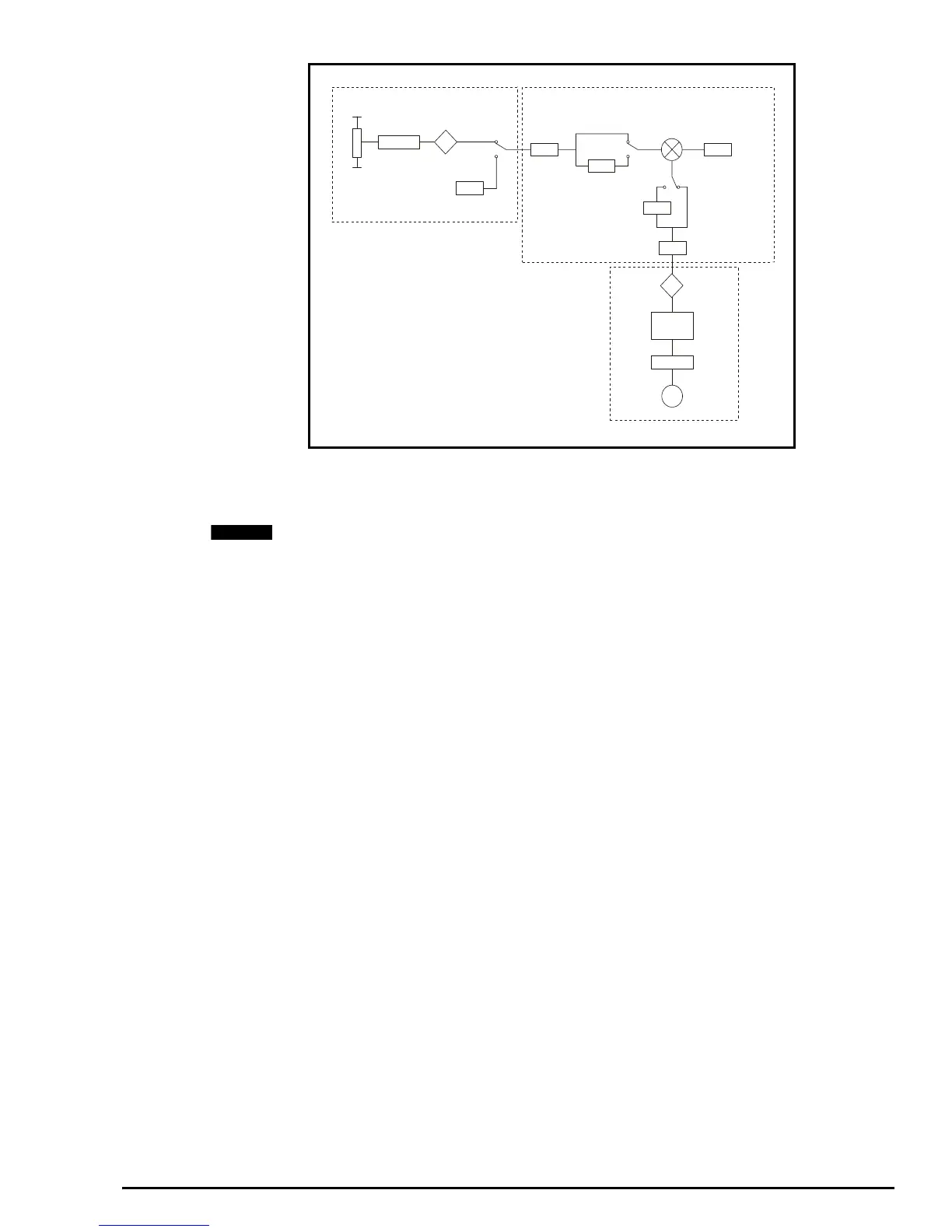

Drive set-up

Parameter set-up

Firstly, establish the actual speed in Hz that is needed to maintain the required pressure for the system. This should be

set by the potentiometer or terminal 2 or by the value in preset speed 1.22. This will be the speed set point.

On terminal 2, 0 - 10V = 0 - 100%

Parameter 1.22, 0 - 1000 = 0 - 100%

Set 7.10 = 0.00 Analog input 1 is not required to be assigned to a destination.

Set 7.14 = 0.00 Analog input 2 is not required to be assigned to a destination.

Set 7.11 for the appropriate feedback range.

Set 14.03 = 7.01 or 1.22 dependant on the chosen speed and set point.

Set 14.04 = 7.02 PID feedback reference assigned to feedback signal from current transducer.

Set 14.08 = 1 Enable PID.

Set 14.16 = 1.36 PID output assigned to control the final speed reference, which will increase or decrease

automatically depending on the errordetected and therefore maintain a constant pressure.

It may be necessary to adjust the internal PID gains 14.10, 14.11 and 14.12 to improve system stability and response.

Perform a Save routine: xx.00 = 1000 and press red Stop / Reset button on drive.

With this set-up, as the feedback signal increases the speed of the motor will decrease and vice versa.

For level control and temperature control, as the feedback signal increases the speed of the motor should increase. To

achieve this, set 14.06 = 1 and 14.05 = 1 to invert the feedback signal.

Terminal 2

7.01

+10V

0V

1.22

14.03

X-1

0

1

1.36

X-1

1

0

14.04

7.02

Terminal 5

Mode

7.11

T

Set point PID loop

Feedback

Speed

reference

NOTE

Loading...

Loading...