2-87

1010PVNFM-3A

Section 2

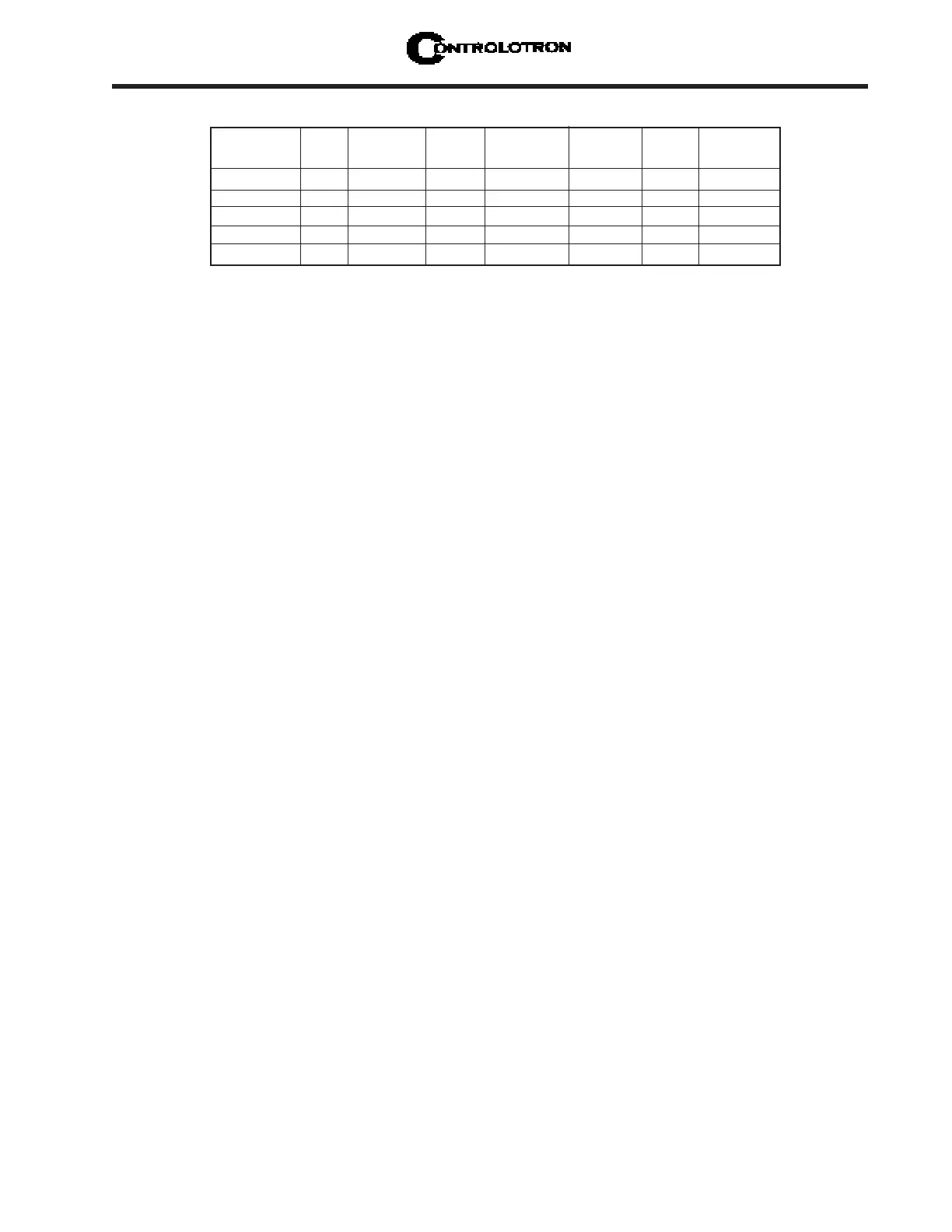

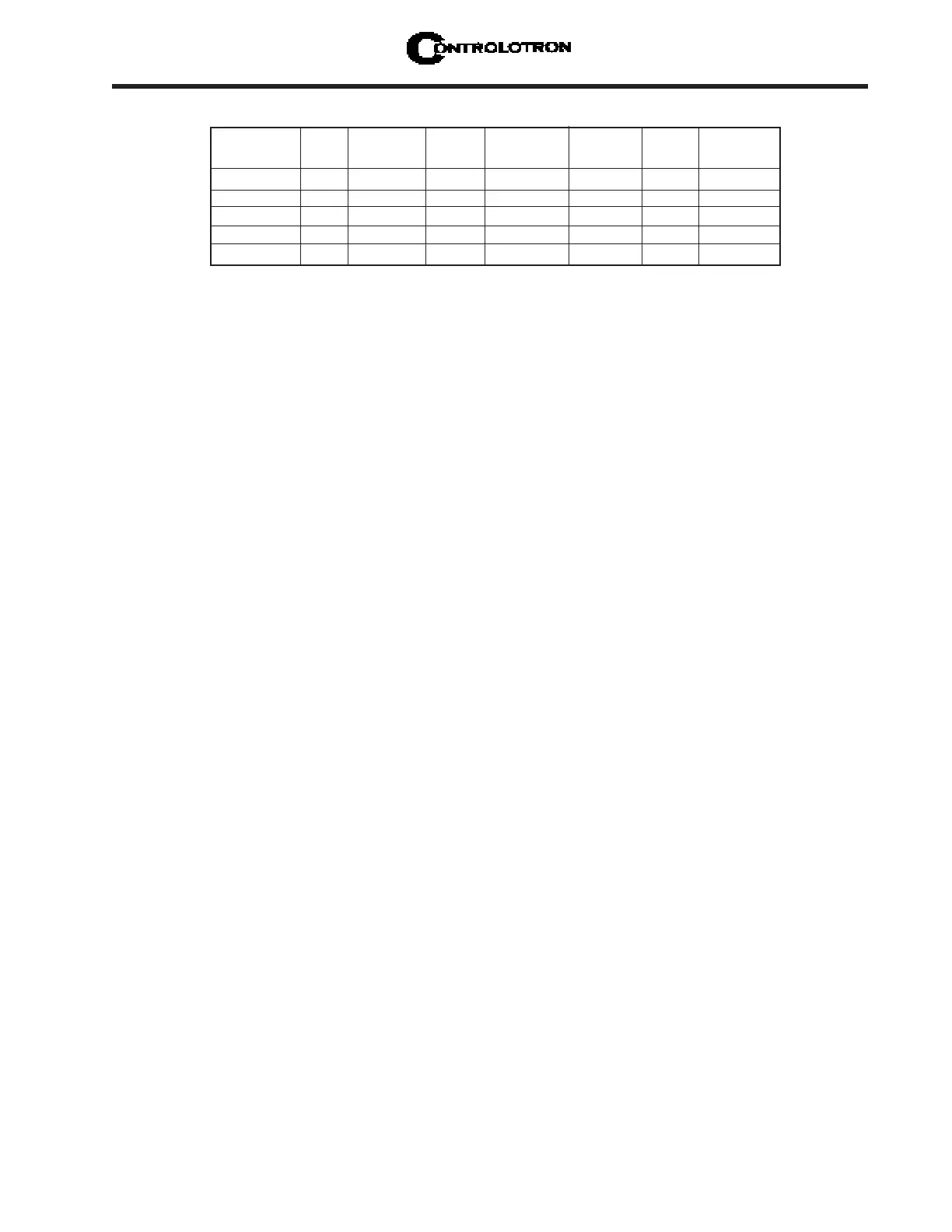

Part Xdcr Pipe Pipe Wall Mount Letter Number

Number Size OD (mm) Mat’l Thk (mm) Mode Index Index*

996PSP-0 0 61.47 PVC 1.93 Direct A 6

996PSP-1 1 63.02 PVC 1.96 Direct A 9

996PSP-2 2 69.67 PVC 3.45 Direct A 6

996PSP-3 3 95.45 PVC 8.74 Direct A 1

996PSP-4 4 165.1 PVC 25.4 Direct** A 0

* The flow computer generates the Number Index.

** See note below.

996PSP PIPE SIMULATOR CHART (Metric)

NOTE: When using a 996PS-4 Simulator, you must access the [Application Data] menu,

select [Liquid Type] - [Other], then program the [Estimated Vs] for a value of

2100 m/s.

6. Access the [Pick/Install Xdcr] menu. Access the [Transducer Model] menu cell. Enter the

Transducer Model option list. Select [991 Universal].

7. Check the [Transducer Size] menu cell. If necessary, enter the Transducer Size option

list and pick the actual transducer under test.

8. Check the [Xdcr Mount Mode] menu cell. Adjust as necessary to match the simulator

chart above.

9. Move the highlight down to [Install Completed?]. Access the option list. Move the cursor

to [Install]. Press <ENT> to start the transducer install routine.

10. Check to make sure that the flow computer returns the Number Index listed in the chart

above. Next, review and verify the Diagnostics data items as described previously. If the

computer, cables and transducers are operating properly, then review all site conditions

to locate the operating problem.

If a Pipe Simulator/Test- Block Test Fails:

1. Replace the transducer cables. If this allows you to complete the test as described above,

then the cables were defective.

2. If the cables are proven to be good, replace the transducers on the pipe simulator with a

“known good” set. If the system functions properly, then the original transducers under

test are defective. Please return any defective transducers to Controlotron for repair.

3. If you replace the transducers and cables, and the system still fails to function correctly,

then it is likely that the computer has a malfunctioning circuit module. If you have spare

modules you may try module substitution to identify the defective module. Otherwise,

please call Controlotron’s Technical Service Department for further instructions.

Loading...

Loading...