3-12

1010PVNFM-3A

Section 3

of the second area prepared, secure the spacing bar to the already mounted transducer by

inserting the transducer index screw through the REF hole on the Bar. Put mounting strap

around transducer and tighten as in Step 5. Sight along spacer bar to ensure axial alignment

to the pipe. Adjust if necessary and do not overtighten. Ensure that the transducers do not

move while tightening.

7. Connect the transducer cable, ensuring that you have observed the upstream/downstream

orientation in respect to the cable and the input jack on the flow computer. If this is a dual-

channel unit, make sure you are connecting the cables to the correct channel’s input jacks.

Repeat this procedure for the number index transducer.

8. Return to the menu, and press <ENT> to finish the transducer install routine.

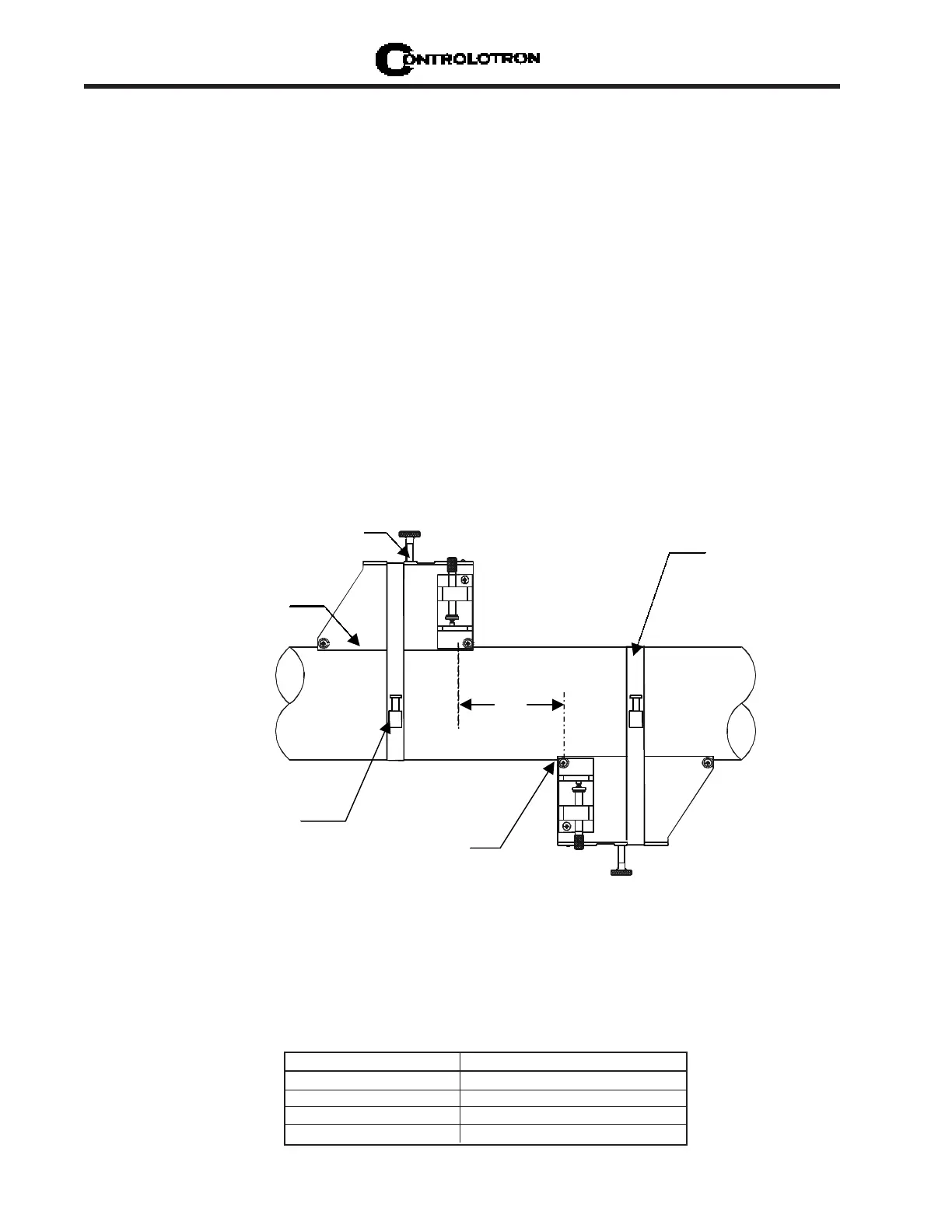

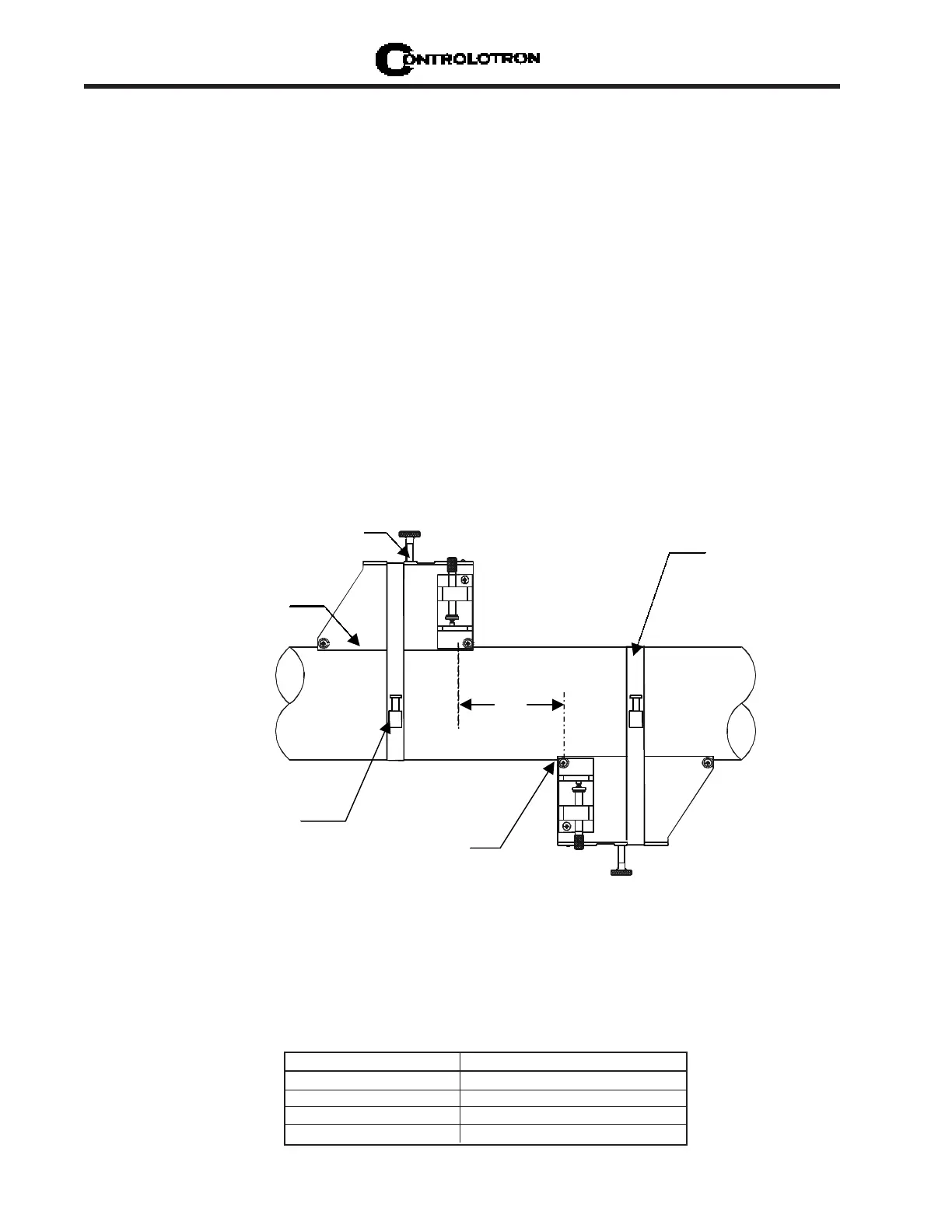

3.1.9 DIRECT MODE - MOUNTING FRAMES, SPACER BAR AND SPACING

GUIDES

The combination of mounting frames, spacer bar and spacing guides is the recommended way

to mount Direct Mode transducers. The mounting frame establishes the axial alignment of the

transducers, and allows you to remove and replace either transducer while preserving their

exact mounting location.

For Direct Mode mounting, you will use a spacer bar to establish the distance between trans-

ducers and a spacing guide to easily locate the transducers at the nine o’clock and three

o’clock positions. Should the distance between transducers be beyond the span of a spacer

bar, a measuring tape can be used. The Mylar spacing guide comes in various lengths and

widths to accommodate most pipe sizes (see list below).

Spacing Guide P/N Size

1012-145-1A 2" x 26" (50.8 x 660.4 mm)

1012-145-1 2" x 45" (50.8 x 1143.0 mm)

1012-145-2 4" x 81" (101.6 x 2057.4 mm)

1012-145-3 4" x 155" (101.6 x 3937.0 mm)

INSTALLATION - DIRECT MODE WITH TRANSDUCERS, MOUNTING FRAMES

SPACER BAR (Not Shown) AND SPACING GUIDE

Ltn

Transduce

Clamping

Screw

Mounting

Frame

Mounting

Strap

Ltn

Reference

Notch

Mounting Strap

Adjusting Screw

Loading...

Loading...