13.2 Preparing machine and Mach3 program

When files are ready, you only need to place and home the materi-

al. First start Mach3 program and reference all the axes pressing

„Ref All Home” button on the main screen.

Place the material securely, to avoid a risk of its shifting or break-

ing during the treatment.

As it was mentioned at the beginning – to

set the material base we are going to use

the carbide roller, filed precisely on half of

diameter. If we use tool length measure-

ment, then enter the tool number “1” in a „Tool” box in Mach3 program and start

the measurement by pressing „Auto Tool Zero” button.

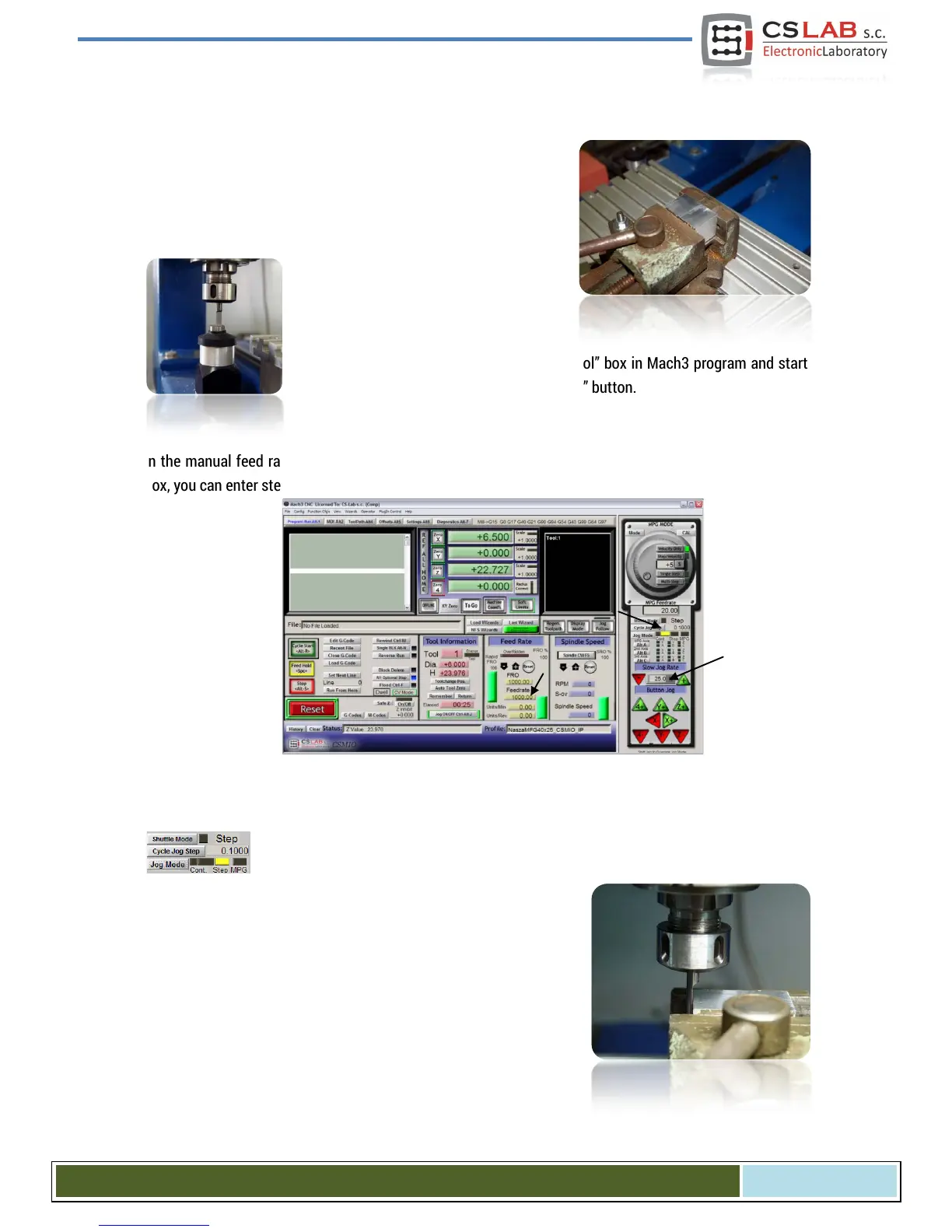

In the manual feed rate panel set continuous ride mode and 25% speed. At the same time in a Feed rate

box, you can enter stepper work feeds, which we will use in a moment -1000 mm/min.

Now use arrow keys or keys on a machine desktop, reach left edge of the material. Z-axis is a little below

the material level.

Next, change the feed mode for stepper mode and set the step on 0.1mm. Working with

0.1mm step we get close to the material and then switch to 0.025mm step – enter that

value in a text box and press <enter>. Make the half of the filed roller

to contact with side surface of the material. If we will try to move the

spindle with a finger to any side – we will be able to do that only to a

small extent. The roller edges will not let us more. Go by step with

another 0.025mm until you will not be able to move the spindle at all

– it means that the material surfaces and the filed roller adhere to

each other.

CS- Lab s.c. – CSMIO/IP- A - CNC controller

Page 97

Loading...

Loading...