10.10 Selection of inch/mm units

Selection of units by which the axes in „Motor Tuning” are scaled is set in

„ConfigSelect Native Units” menu position. Select unit in the window and close „OK”.

Selection of units for a treatment is done by G20 (inch) and G21 (mm) commands.

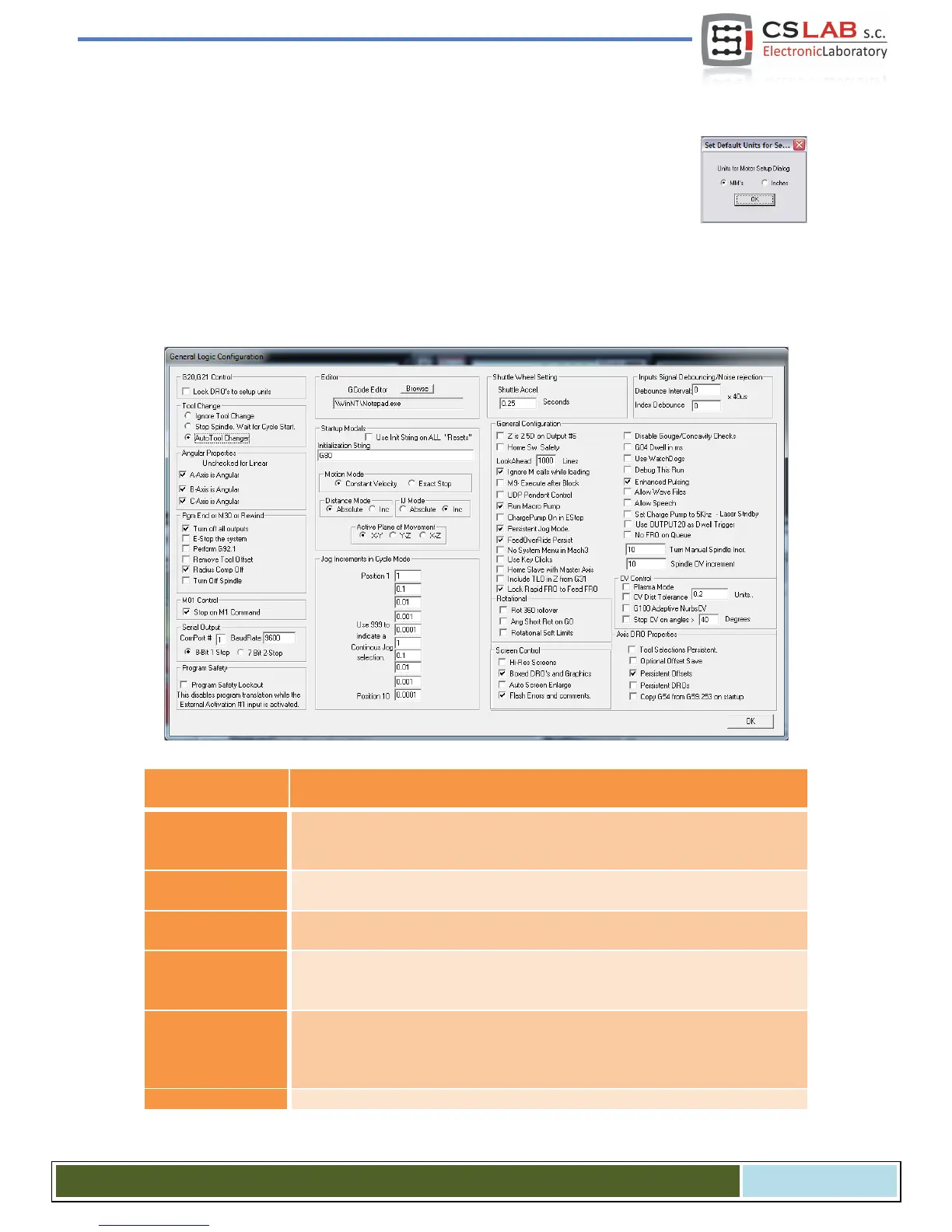

10.11 Some parameters in the General Config window

In the „ConfigGeneral Config” menu, you find basic configuration parameters of Mach3. Many of them

don’t need any modifications, but it is worth to change some of them. In the picture below, you can see a

table with the most important parameters and a short description of each one.

Configuration of an automatic tool changer. An important issue: even if we do not have

an automatic tool changer but we use a tool measurement sensor - the Auto Tool

Changer should be selected. Otherwise, Mach3 will not take tool length into account.

Checking the box, we select, if A, B, or C axis works as angular. Unchecked box means

that the axis works as linear.

It is about behavior at the end of a program, M30 or REWIND command.

Motion mode selection: Constant Velocity or stop at every trajectory section (Exact

Stop). The Exact Stop mode may be more precise in some cases but much more slowly.

Constant Velocity mode is used in 99% of cases.

Data format for circular interpolation. Usually "Inc" should be selected. After loading the

trajectory, generated with CAM program, if there are problems with circular interpolation

(like large circles in a 3D preview), you can try to switch to „Absolute” and then load G-

Default plane for circular interpolation G2/G3. Usually X-Y for milling machines, X-Z for

CS- Lab s.c. – CSMIO/IP- A - CNC controller

Page 75

Loading...

Loading...