Installing Accessories 35

Cat. No. 01029401

Aqua-Sensor

®

(P/N 01025279)

Aqua-Sensor

®

probe detects and initializes a regeneration based on exhaustion of the resin bed, which is monitored by

electrical conductivity. The conductivity is also monitored in the resin during regeneration to determine the brining process

has been complete and to optimize the slow rinse times, potentially saving water.

WARNING! For best results, do not subject the Aqua-Sensor® to conditions outside the operat-

ing parameters of the water softening system. See page 3.

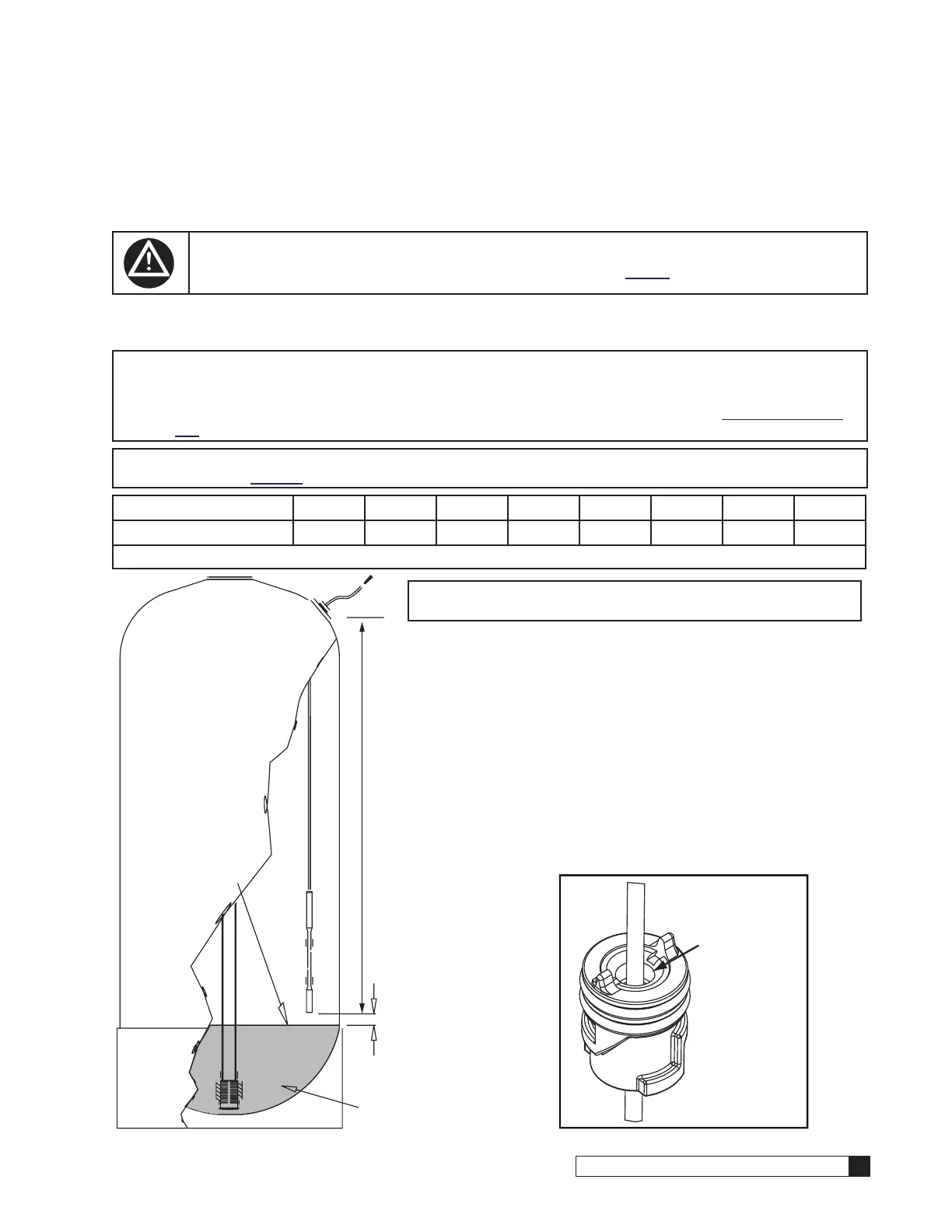

Adjust the cable to the proper length for the CTM tank size. The small center plug can be loosened to allow cable move-

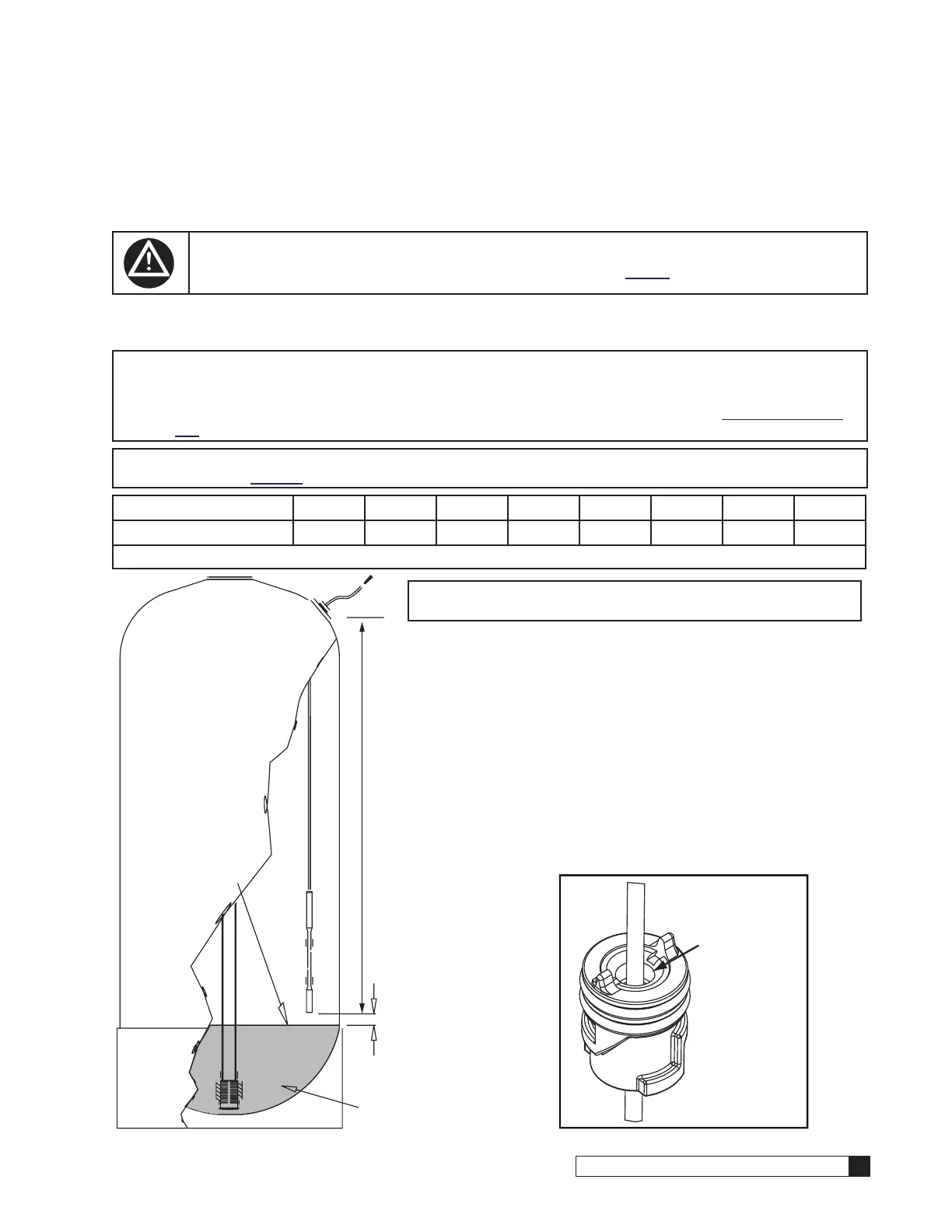

ment and then retightened with pliers to prevent leaks. Remove the Fillport plug by turing it a 1/4 turn and lifting up on the

plug. Lube the o-ring of the Aqua-Sensor probe plug before inserting it into the port.

NOTE After installation of the Aqua-Sensor probe, a complete regeneration is required to set the probe at its

proper depth, and record the conductivity in the tank. Refer to GBE Programming for Commercial Soft-

eners and Filters (except for HFxN) Manual (P/N 01027295) for programming information. This manual

can be obtained from your local dealer, CPort (www.cport.culligan.com) under the Technical Service

Tab or on the Service Tech App.

NOTE Aqua-Sensor probe requires the connection of the 2.5V power cord to the transformer and circuit

board. See page 23 for details.

Softener Model

60K 90K 120K 150K 210K 300K 450K 600K

Recommended “A”

37.5” 42.6” 54.4” 52.5” 52.5” 62.1” 55.0” 54.8”

NOTE Measurement to the bottom of the probe allows for a 30% reserve capacity.

Figure 44. Aqua-Sensor

®

probe positioning.

A

Gravel Underbedding

Bottom of Resin Bed

Small

Aqua-Sensor

®

Plug

1” minimum from bottom of

probe to gravel bed.

Aqua-Sensor probe should

be completely within the

resin bed.

NOTE If used in a multiple tank configuration, lower the probes

to be just above the underbedding.

Loading...

Loading...