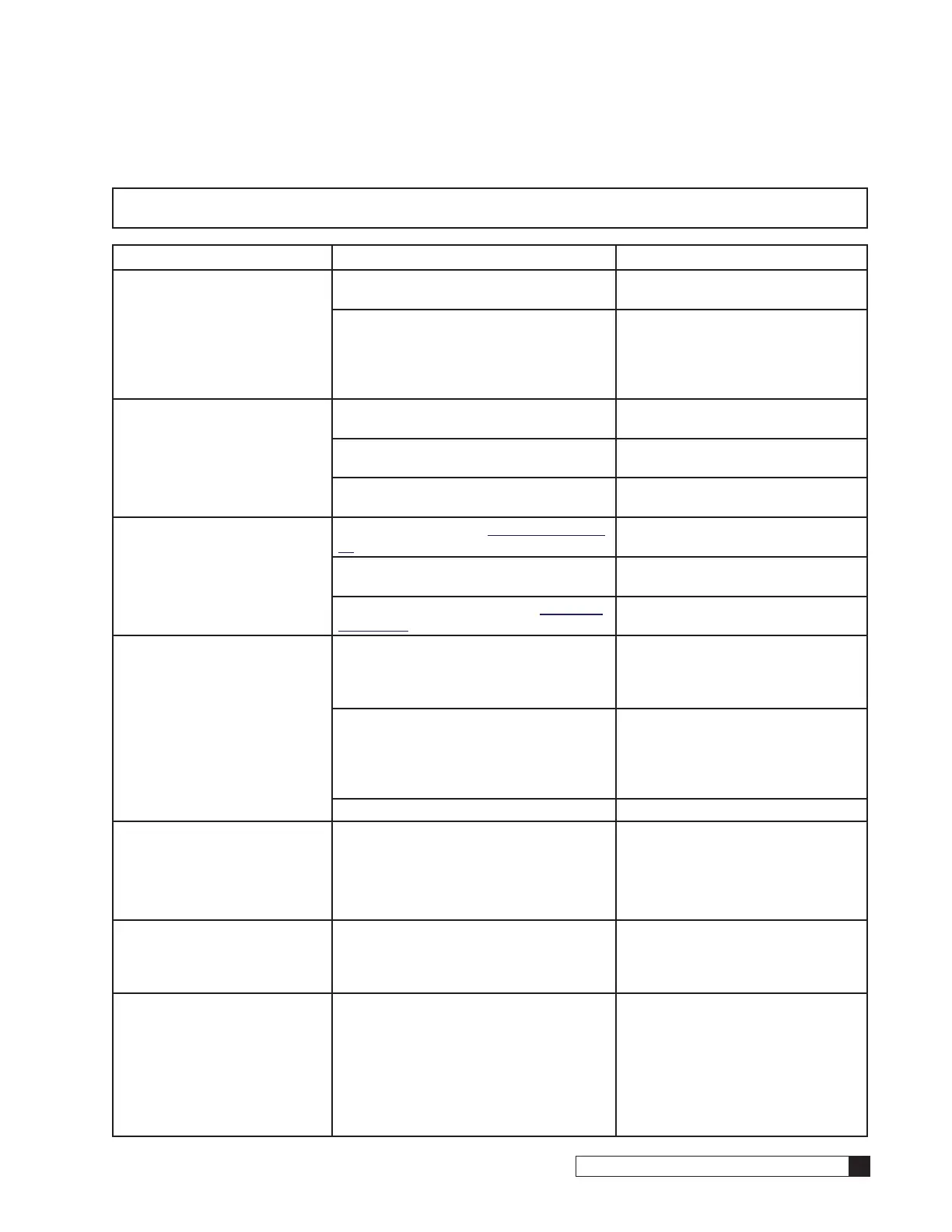

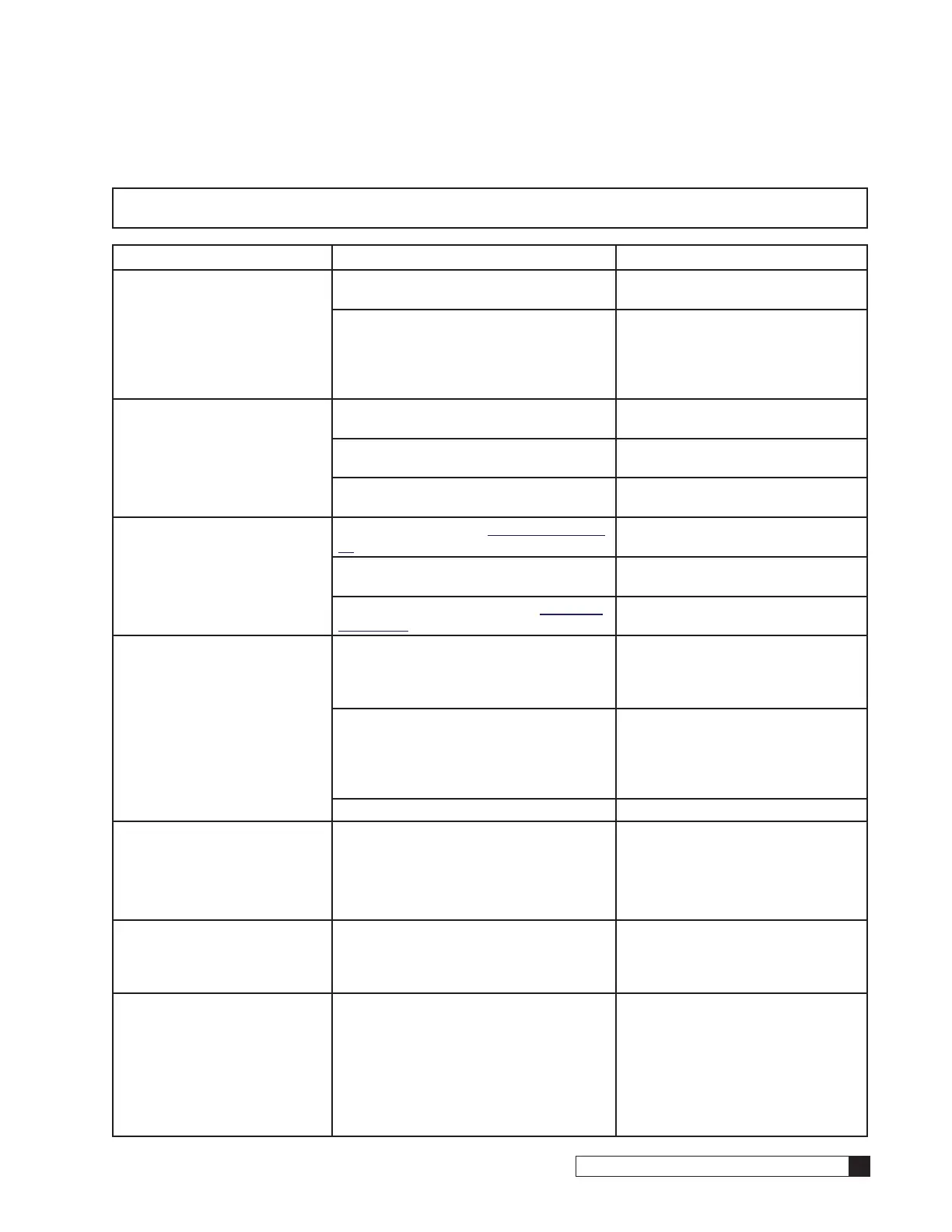

Troubleshooting 65

Cat. No. 01029401

General Troubleshooting

NOTE Error Codes can be found in the GBE Programming for Commercial Softeners and Filters manual

(01027295)

PROBLEM OR SYMPTOM CHECK PROCEDURE CAUSE

Slight Leak to Drain Disconnect pilot valve tubing at drain port

on the valve.

Flow from tubing indicates leaky seal

in pilot valve spool.

If pilot valve is not leaking, use a test kit

and check for hard water at the drain.

Possible missing or damage pis-

ton/cap O-Rings or T-Seal. If water

tests soft then fast rinse drain piston

is open. If the water tests hard then

backwash drain piston is open.

Leak at the Pilot Valve Check to see if the leak is at the top clamp,

valve manifold and/or outer spool body.

Pilot spool body o-rings are missing or

damaged.

Check to see if the leak is at the drain port

on the valve manifold.

Pilot spool o-rings damaged.

Check to see if the leak is at the pilot spool

shaft and/or inner pilot spool body

Pilot spool shaft o-rings damaged.

Leak around the Outside of the

Valve Core

Check drain holes (See Figure 79 on page

69)

See the Check Procedures and Caus-

es for “Leak at the Pilot Valve”.

Check the o-rings on the couplers of the

valve manifold

O-rings are missing or damaged.

Check Piston #7 vent port. (See Figure 78

on page 69)

No damage to valve. Expolusion of

water built up from factory testing.

High Flow to Drain During

Service

Check position dial pilot. If not in Position #1, manually cycle

the pilot drive assembly to Position #1.

If the flow stops, check the pilot drive

assembly.

Use a test kit and check the hardness of

the water at the drain.

Use a test kit and check the hardness

of the water at the drain. If soft then

fast rinse drain piston is open. If the

water tests hard then backwash drain

piston is open.

Check the feed water pressure Water pressure is less than 35 psi.

Piston Does Not Close or Open.

CAUTION: make certain that

the water pressure is relieved

from the system before remov-

ing the spool manifold.

Turn off the water pressure, remove spool

manifold, then remove piston from control

valve.

If there is no flow from the tubing, the

pilot strainer may be plugged.

• T-Seal may be dirty, worn or loose.

• Seat may be eroded.

• Upper piston o-ring may be torn.

Piston Does Not Open Turn off the water pressure, remove clamp,

remove external plumbing connections then

remove valve body from tank adapter. Visu-

ally inspect T-Seal.

T-Seal may be fouled or swollen.

Hard Water Leakage Into the

Service Lines.

CAUTION: make certain that

the water pressure is relieved

from the system before dissas-

sembling the control valve.

Inspect the bypass piston. If no flow from the tubing the pilot

strainer is probably plugged.

• T-Seal may be dirty, worn or loose.

• Seat may be eroded.

• Upper piston o-ring may be torn.

Build-up on the inside of the valve

cavity may be preventing the piston

assembly from seating.

Loading...

Loading...