66 Culligan® Culligan Top Mount (CTM) Water Softeners

66 Cat. No. 01029401

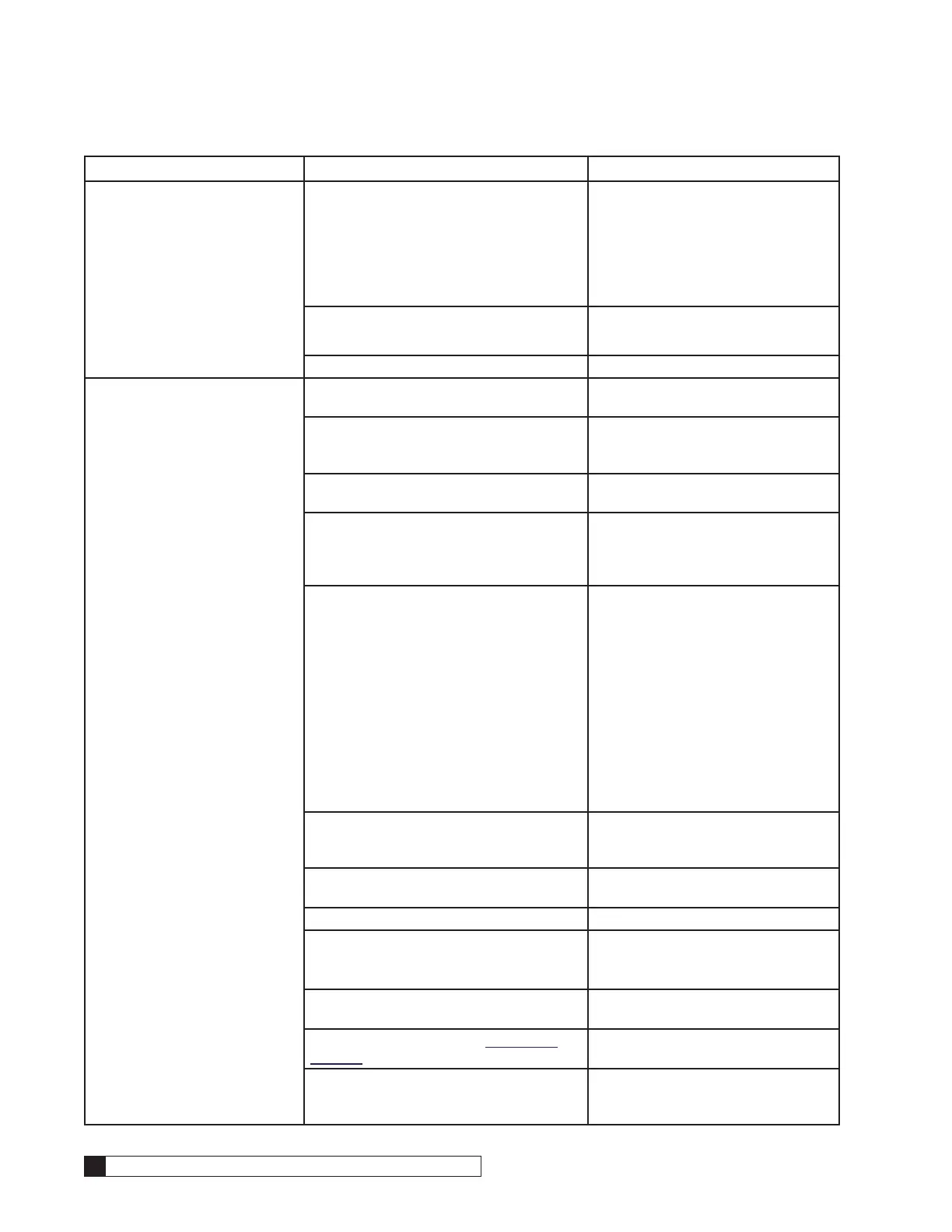

PROBLEM OR SYMPTOM CHECK PROCEDURE CAUSE

Restricted or No Service Flow Either Service Inlet piston or Service Outlet

piston are not opening fully. To determine

which one, turn the pilot to position #2. Ob-

serve the flow to the drain. Cycle the pilot

to position #4 and compare the flow of wa-

ter in position #4 to the flow in position #2.

Return the pilot to position #1.

Flow should be the same for both po-

sitions but if not:

• Service Outlet piston is not open-

ing properly.

• If backwash (position #2) is higher,

then Service Inlet piston is not

responding properly.

Potentially clogged distributors or compact-

ed media bed.

Failed distributors.

Contamination of resin bed.

Check feed water pressure Water pressure is less than 35 psi.

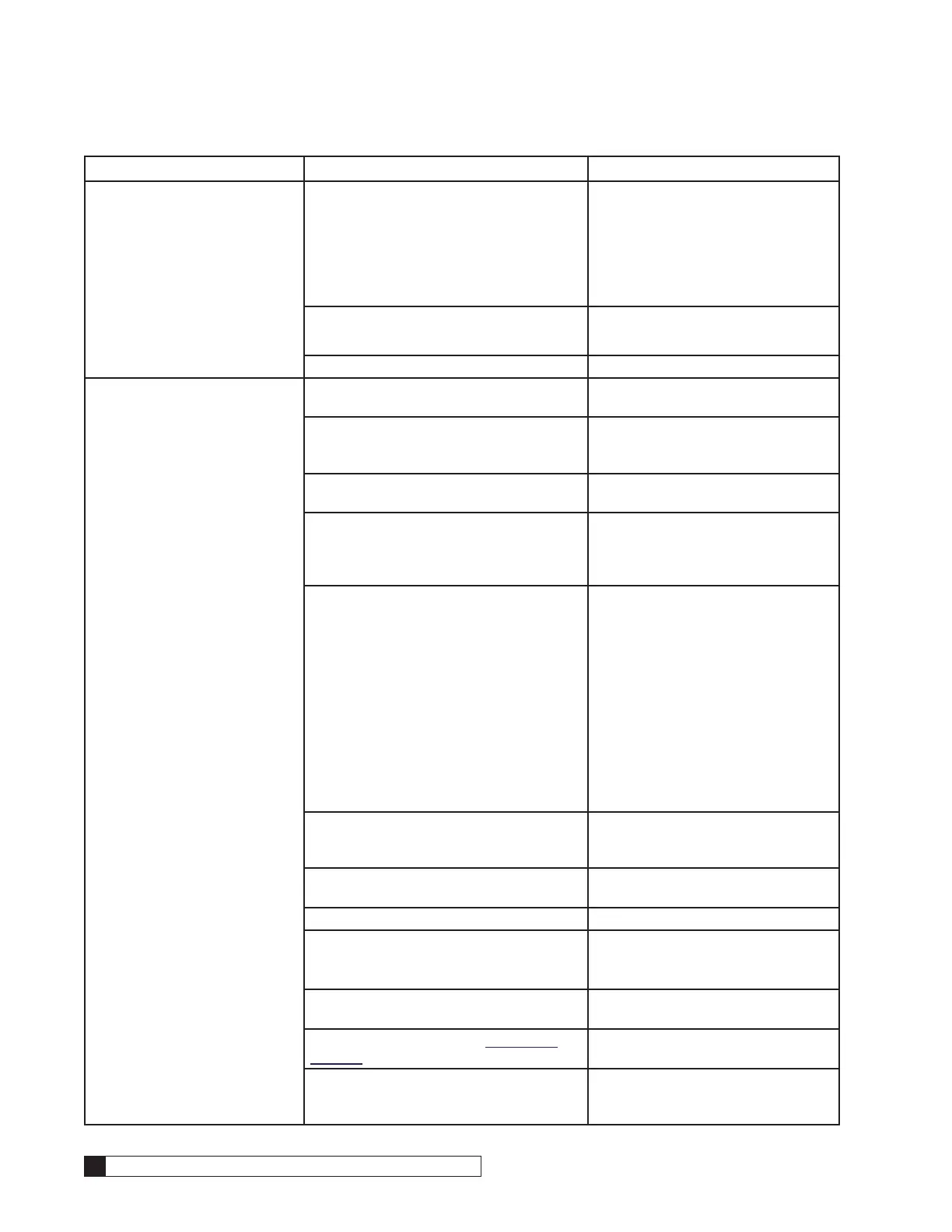

Failure to Draw Brine/Restricted

Brine Draw

Check that the brine line is unrestricted. Restrictions will not allow the system

to draw brine.

Check water level in brine tank Failure to Refill properly. Check

“Check Procedures and Cause for

Failure to Refill”.

Check the feed water pressure. Water pressure must be a minimum of

35 psi during regeneration.

Verify the pilot is in the #3 (brine draw)

position.

If the pilot is not in the proper position

for the brine draw/slow rinse cycle, the

system will not draw brine. Check the

pilot drive assembly.

Verify there is a vacuum on the brine line. If there is a vacuum, the brine valve

should have 20 - 27 in.Hg. No vacuum

indicates:

• Drain line is too small or discharg-

ing at a level too high above the

floor.

• The pilot strainer is plugged.

• Pistons are not in the correct posi-

tion. Refer to flow table. Possibly

broken piston.

• Plugged or incorrect backwash

flow control.

• Dirty resin bed.

Place pressure gauge downstream of drain

flow control

The back pressure of drain line down-

stream of the flow control is greater

than 5 psi.

Visually inspect eductor for blockages Plugged eductor , eductor filter, or

eductor nozzle

Inspect eductor o-rings Missing or damaged eductor o-ring

Inspect brine refill elbow assembly Plugged brine refill elbow assembly

Check piston stuck or plugged

Plugged brine refill elbow filter

Check correct function of brine valve inside

the brine tank

Not working properly

Inspect eductor and refer to Table 5 on

page 17.

Incorrectly sized eductor

Check feed water pressure is always above

35 psi.

Low feed water pressure to the pilot

valve will prevent proper setting of the

pistons.

Loading...

Loading...