94 Culligan® Culligan Top Mount (CTM) Water Softeners

94 Cat. No. 01029401

Appendix B Aqua-Sensor Guidelines

Aqua-Sensor Application Guidelines

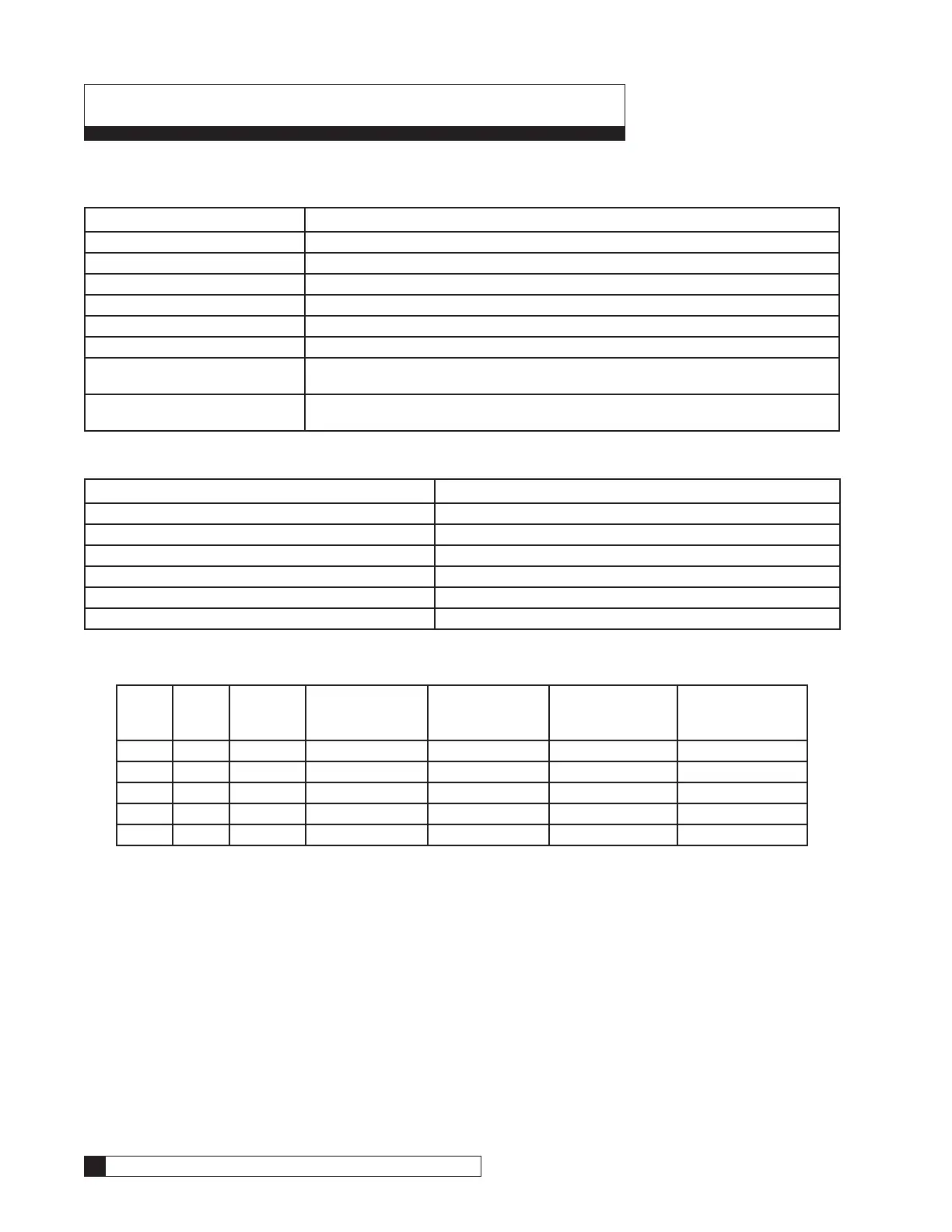

Table 19. Aqua-Sensor Application Guidelines

Parameter Value

Hardness (gpg as CaCO3) 7 - 99 (See Notes 1 & 2)

Soluble iron (ppm as Fe) < 2 (See Note 3)

Manganese (ppm as Mn) < 0.5 (See Note 4)

Hardness versus Salt Dosage See Table 20 and Note 2

TDS to Hardness Index TDS hardness (as CaCO3) <10 (i.e., hardness must be at least 10% of TDS; see Note 5)

Temperature, °F Any within equipment’s operating range

Alum and phosphate Anecdotal evidence indicates potential foulant; effect has not been confirmed

experimentally

Commercial cell: distance between

sensing and reference cell pairs

6 inches (See Note 2)

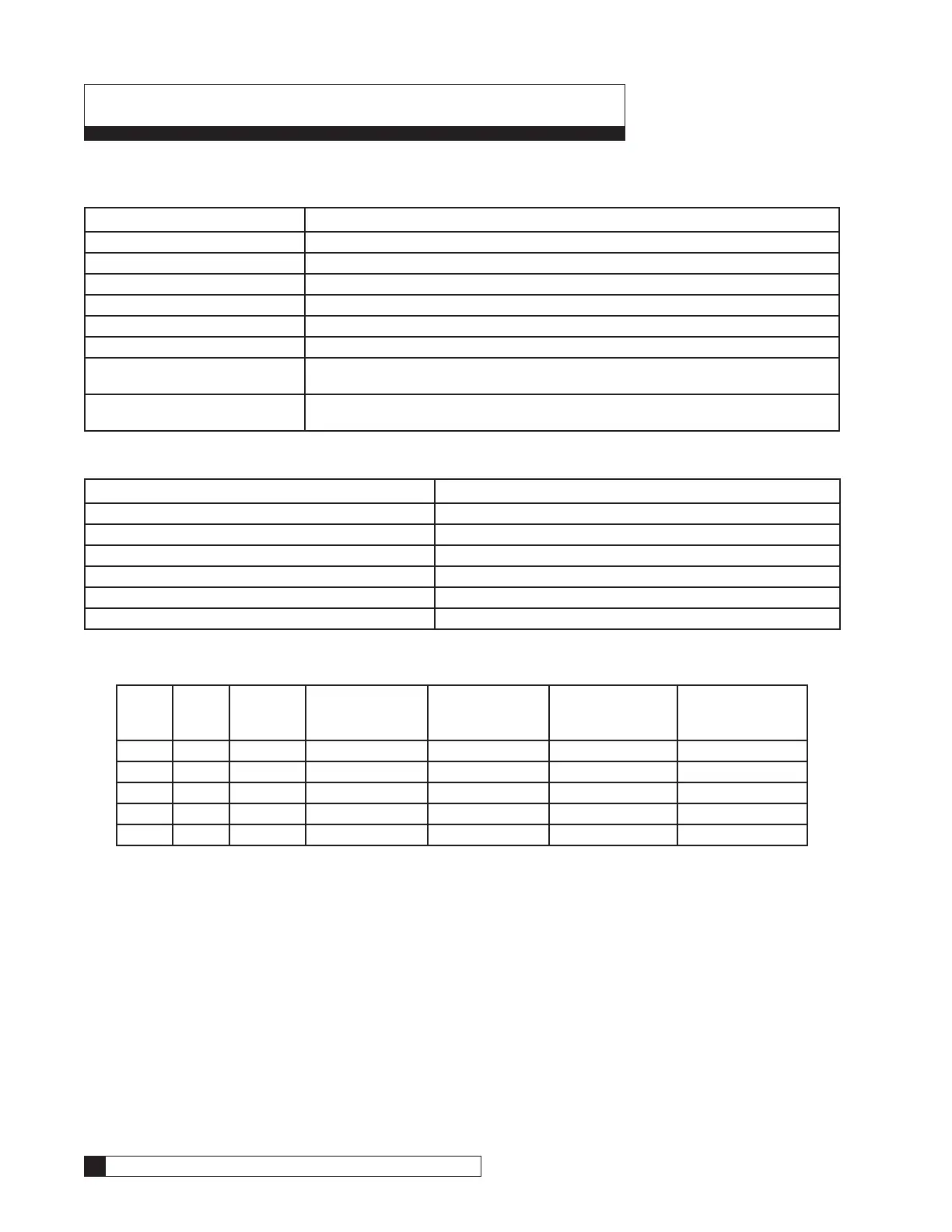

Hardness vs. Salt Dosage

Table 20. Hardness vs. Salt Dosage

Hardness (gpg as CaCO3) Recommended Salt Dosage (lbs/ft

3

)

7-10 5-6

10-15 6-8

15-25 8-9

25-50 9-11

50-75 11-12

75-99 12-16

Resin Bed Depth and Estimated Capacity per Inch at Various Salt Dosages (Downflow)

Table 21. Resin Bed Depth and Estimated Capacity per Inch at Various Salt Dosages (Downflow)*

Model

Resin

Qty

Depth

of Resin

(in.)

Grains Capacity

per inch (15 lb/

ft³ salt dosage)

Grains Capacity

per inch (6 lb/ft³

salt dosage)

Grains Reserve

Capacity@15 lb/

ft³ salt dosage

Grains Reserve

Capacity@ 6 lb/

ft³ salt dosage

60K 2 22.5 2667 1778 16002 10668

90K 3 25.8 3488 2326 20928 13956

120K 4 34.4 3488 2326 20928 13956

150K 5 34.0 4412 2941 26472 17646

210K 7 35.0 6000 4000 36000 24000

* 300K, 450K and 600K models were not designed to be used with an Aqua-Sensor.

NOTE

1. Although the Aqua-Sensor device has been used successfully on water with hardness as low as 3 gpg, there is an increased

risk of missed signal (no regeneration) when the hardness is less than 6 gpg.

2. For each tank diameter, there is a specific volume of resin in the space between the cell pairs. The capacity of that resin is

influenced by hardness and salt dosage. Any combination of flow rate and hardness that causes the hardness front to pass

through that volume of resin in less than 6 minutes will result in the sensor failing to detect the need to regenerate. In gener-

al, the volume of resin between the cell pairs on commercial units will permit a proper signal at or below the continuous flow

rating when raw water hardness is less than 50 gpg. At higher hardness levels, it may be necessary to reduce the flow rate to

assure adequate sensor signal duration.

3. If precipitated or bound iron is present it must be removed before the softener.

4. Manganese can deposit on the sensor electrodes, particularly on the upper pair, causing missed signals (no regeneration).

Periodic cleaning may be needed to maintain satisfactory performance.

5. Adequate signal strength has been demonstrated at ratios as high as 14, but signal strength diminishes with decreasing TDS

to hardness index.

6. Amount shown is based on the distance between the referencing cell pairs. Reserve capacity at salt dosages less than 15 lbs

per cubic foot are shown for reference purposes only and may not provide adequate representation of actual capacity per inch

of bed depth for operational purposes.

Loading...

Loading...