68 Culligan® Culligan Top Mount (CTM) Water Softeners

68 Cat. No. 01029401

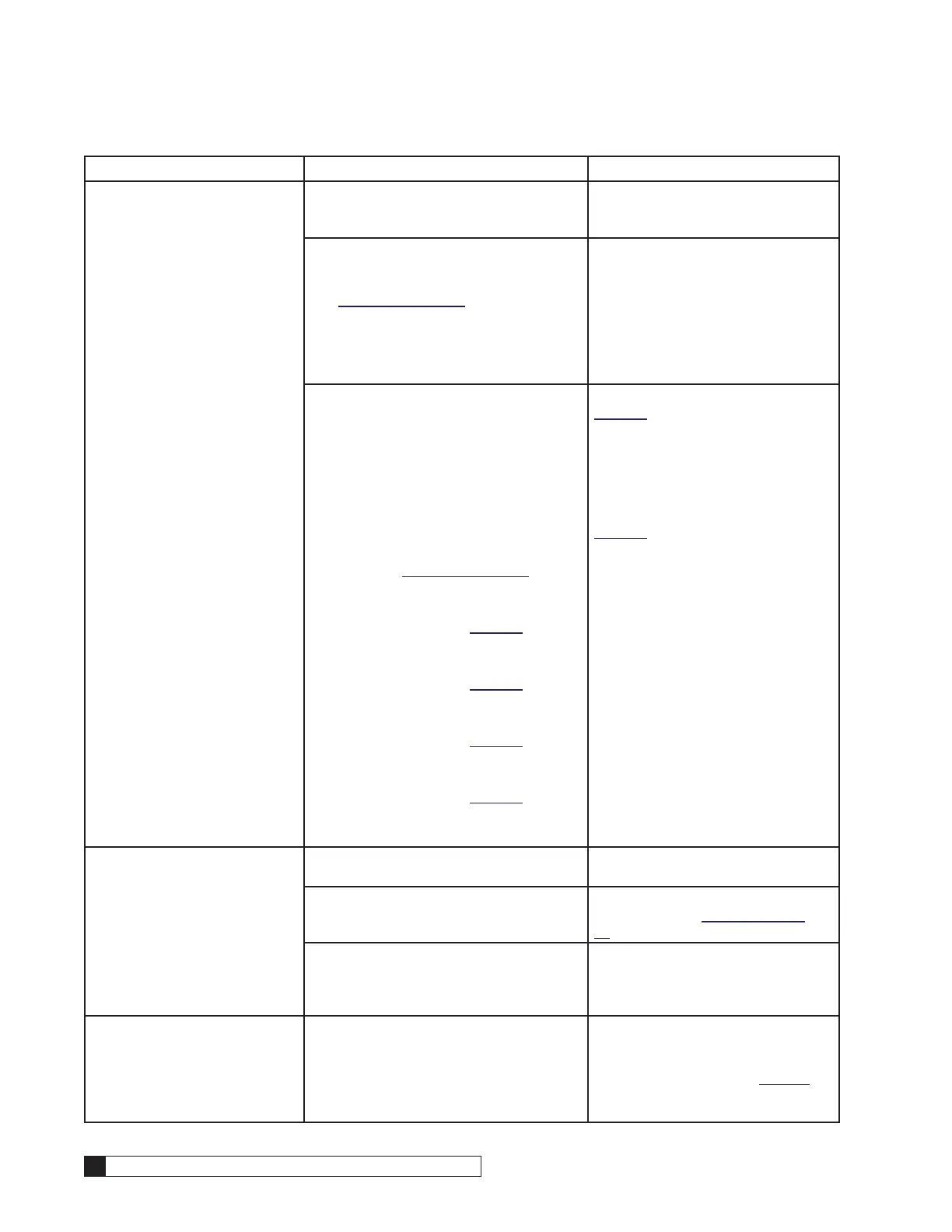

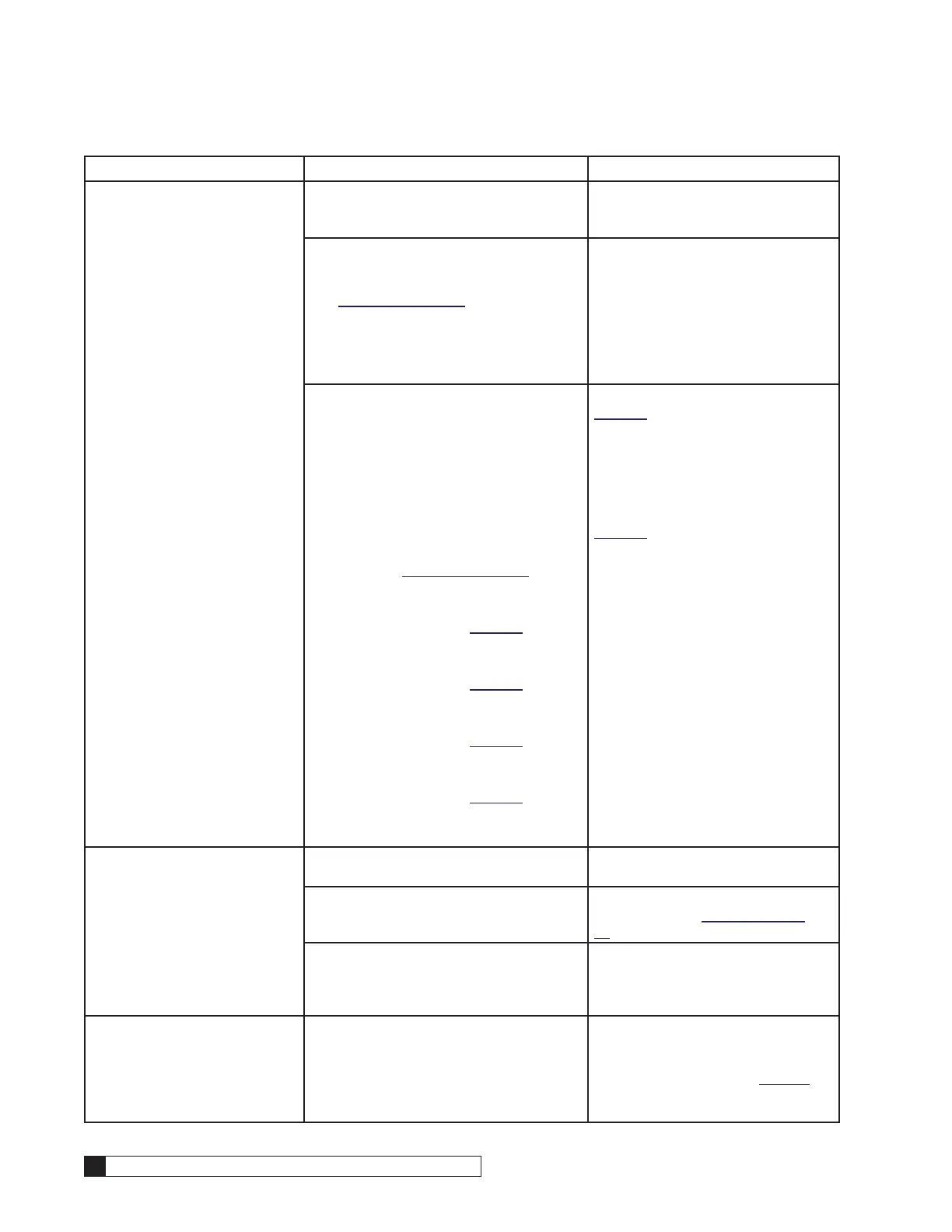

PROBLEM OR SYMPTOM CHECK PROCEDURE CAUSE

Pilot Does Not Pressurize or

Vent Valve Ports Properly

Check Screen on Pilot Strainer Clogged Screen prevents control

pressure from reaching pilot valve

(and solenoid valves if applicable).

1. Using the GBE, manually cycle the

pilot as required until the piston(s) in

question should be closed. (Refer to

Table 13 on page 72). Remove the

tubing from the inlet to the pilot valve

strainer and check for water from the

tube.

2. Manually cycle the pilot to position #1.

If water flows out of the tubing, check

the fitting in the valve inlet port and pi-

lot valve strainer for an obstruction. If

water does not flow out of the control

tubing, check the tubing and fittings

for an obstruction.

1. Remove the external plumbing con-

nections and clamp. Remove valve

body from tank adapter. Lay the valve

body on its side. Attach an external air

supply, hand vacuum/pressure pump

with gauge or water supply to the spool

body pressure port.

2. While in position #1 and not in stand

by (multiple units with blocking sole-

noids). Confirm the correct piston func-

tion using Table 13 on page 72.

3. Using the GBE, manually cycle the pi-

lot to position #2. Confirm the correct

piston function using Table 13.

4. Using the GBE, manually cycle the

pilot to position #3. Confirm the correct

piston function using Table 13.

5. Using the GBE, manually cycle the

pilot to position #4. Confirm the correct

piston function using Table 13.

6. Using the GBE, manually cycle the

pilot to position #5. Confirm the correct

piston function using Table 13.

7. Using the GBE, manually cycle the pi-

lot to position #1.

2 - 4. If piston function does match

Table 13:

• Coupling O-Ring(s) missing or

damaged

• Piston O-Ring(s) missing or dam-

aged

5 & 6. If piston function does match

Table 13:

• Coupling O-Ring(s) missing or

damaged

• Piston O-Ring(s) missing or dam-

aged

• Refill Piston Spring missing or

damaged

Overfilled Brine Tank Remove the valve manifold and check refill

piston spring.

Missing or damaged refill piston spring

Incorrectly sized drain line flow control Replace with the correct drain line

flow control. See Table 4 on page

15

Incorrect programming Correct programming. See the GBE

Programming for Commercial Soften-

ers and Filters, except for HF xN Man-

ual (P/N 01027295)

Softener Tank Does Not Remain

in Stand By Mode or Will Not

Provide Water Thru the Outlet of

the Control Valve When in Ser-

vice (Only systems using block-

ing valves)

Verify operation of the motorized ball valves

of the control valve.

Motorized ball valve may not be prop-

erly wired or water hardness scale

build-up inside motorized ball valve is

causing malfunction. (See page 21)

Loading...

Loading...