3.3 Setting the toothed belt tension

Caution: Danger of injury !

Switch off the main switch.

Check and adjust the setting of the toothed belt tension only

with the sewing unit switched off.

Standard checking

–

Push the transport carriage to the front.

–

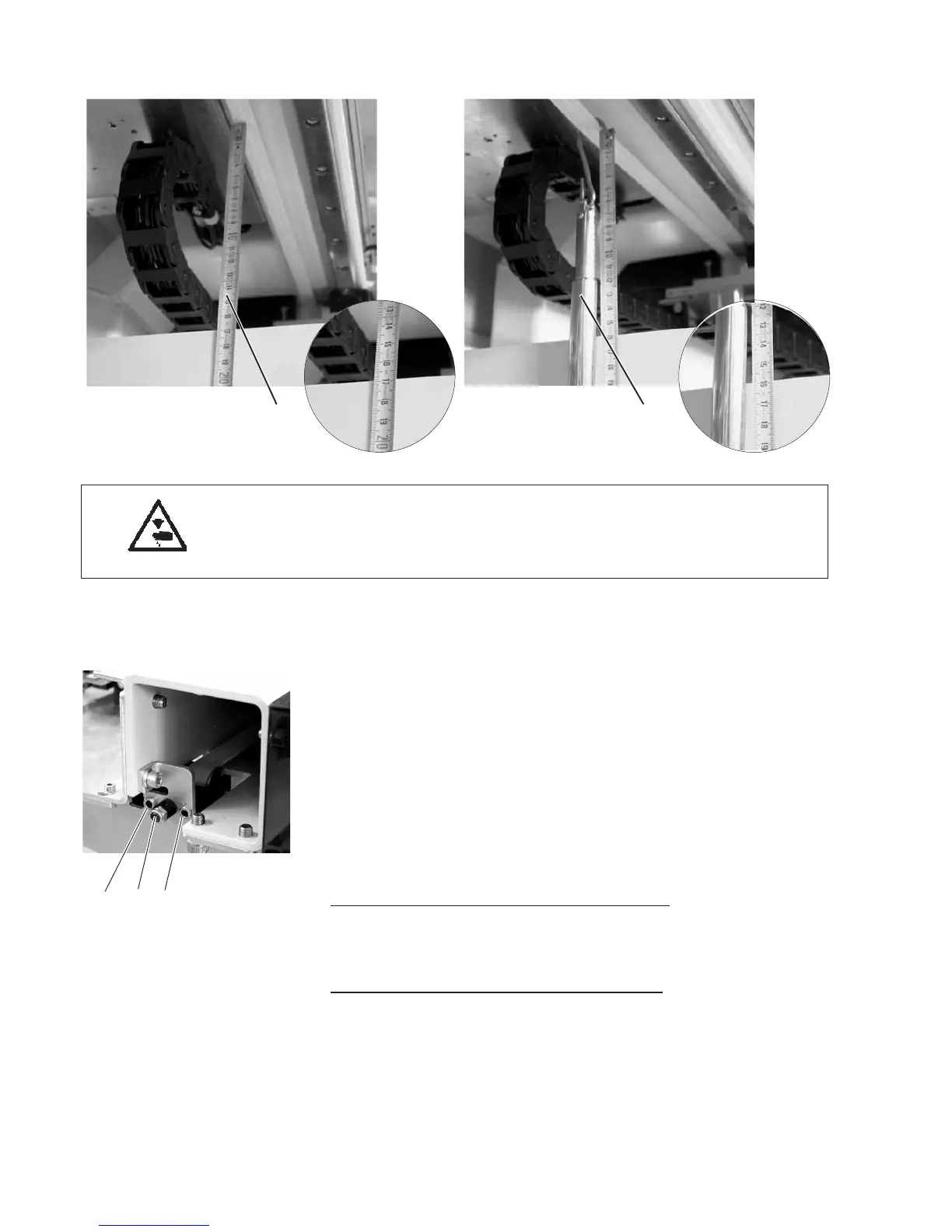

Measure the distance between the toothed belt and the upper edge

of the table top with a measuring tape 1.

–

Pull down the toothed belt with a spring balance 2 and with a power

of 20 N.

–

The toothed belt tension is correct when the distance between

the toothed belt and the upper edge of the table top can be

reduced by 11 mm at 20 N (Example: 170-11 = 159 mm).

Correction

–

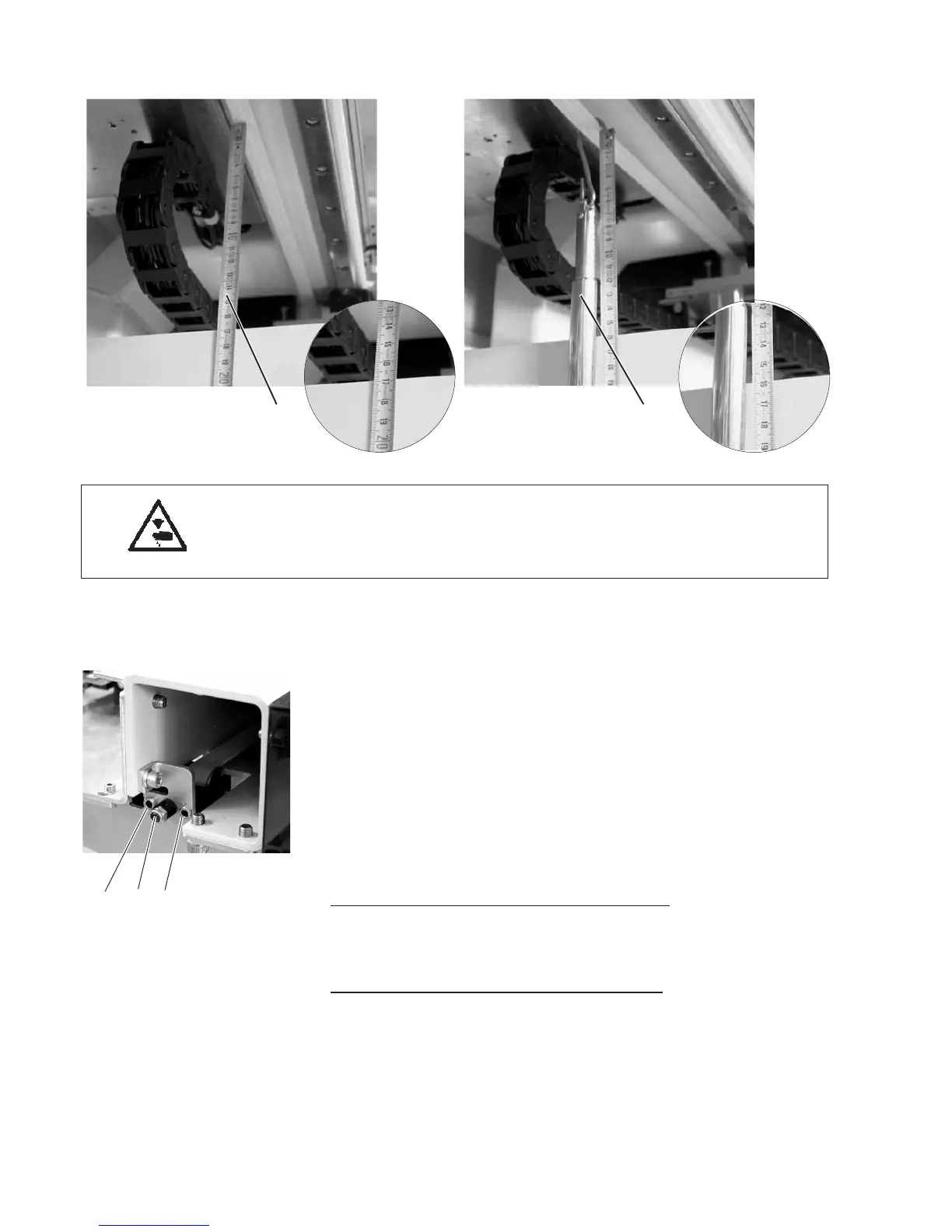

Adjust the toothed belt tension by turning the nut 7.

–

Adjust the belt pulley course through screws 6 and 8.

Consequences of a too high toothed belt tension

–

Reduced durability

–

Noisy running

Consequences of a too low toothed belt tension

–

No faultless meshing between belt teeth and disc toothing

–

The teeth may skip over under load

–

Non-uniform stitch lengths

–

Loss of steps possible

60

1 2

876

Loading...

Loading...