Adjusting the thread system

72

Service instructions 967 - 00.0 - 12/2014

10.Mount the thread tensioning plate with the winder on to the machine.

11.Test the winder for correct operation. Check that the winder switches

off when the thread has been wound up to 0.5 to 1 mm below the outer

diameter of the bobbin (4).

If it does not do so, tighten screw (2) or back it off, and repeat the test.

Once the desired result has been obtained, tighten the locknut (3).

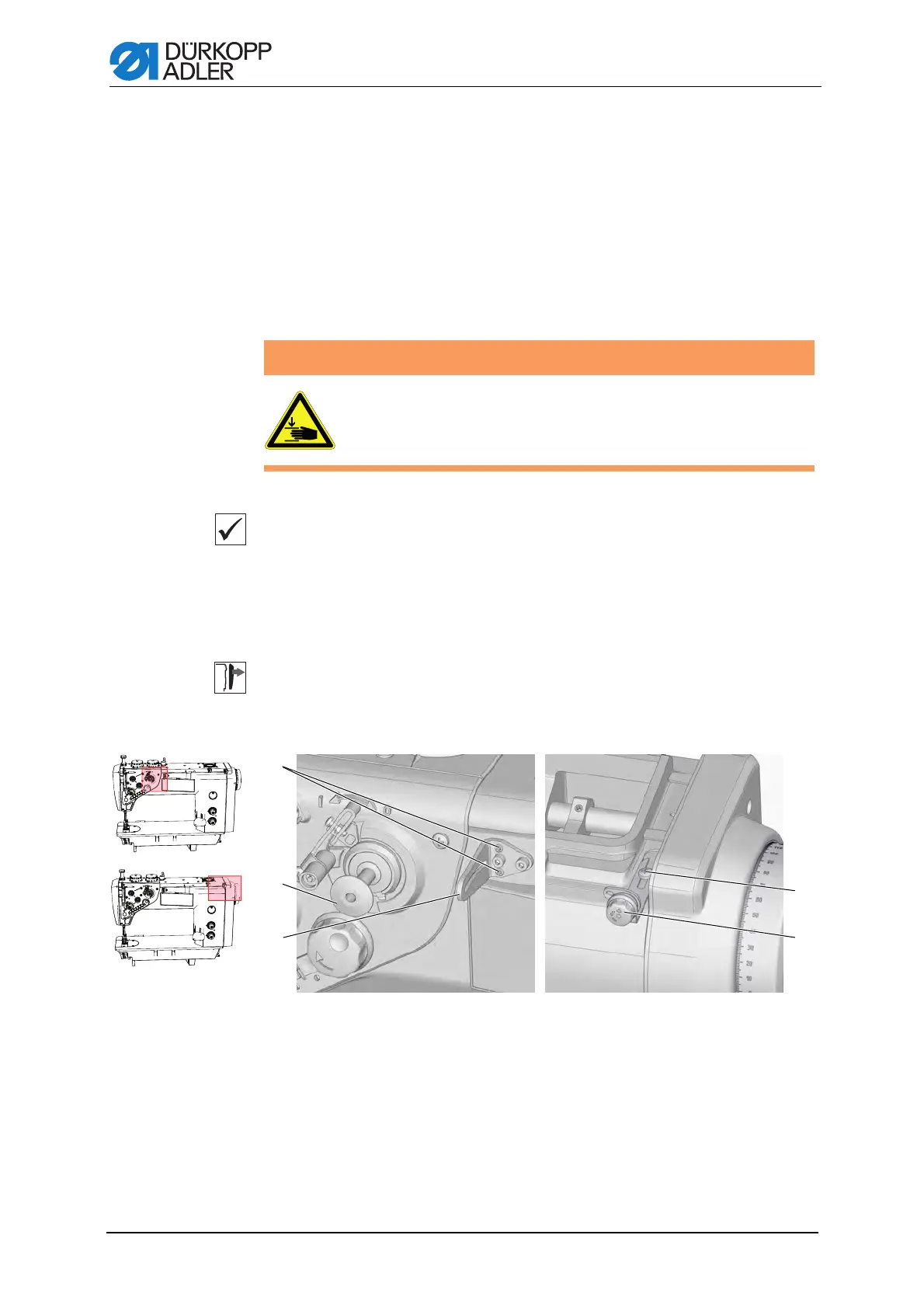

13.3 Adjusting the hook-thread guide

Correct setting

The thread tensioning element (4) must be at a distance from the machine

arm such that the bobbin (2) is wound equally at both ends.

If due to the position of the thread tensioning element (4) the bobbin (2)

cannot be wound equally at both ends, the inclination of the hook-thread

guide (3) must be changed to achieve this.

Cover

• Upper right cover ( page 11).

Figure 50: Adjusting the thread tensioner and guide ahead of the winder

WARNING

Risk of injury

Switch off the machine before making adjustments.

(1) - Setscrews

(2) - Bobbin

(3) - Hook-thread guide

(4) - Thread tensioning element

(5) - Screw

ཱ

ི

ཱི

ུ

Loading...

Loading...