Proline Prowirl F 200 PROFIBUS PA Diagnostics and troubleshooting

Endress+Hauser 161

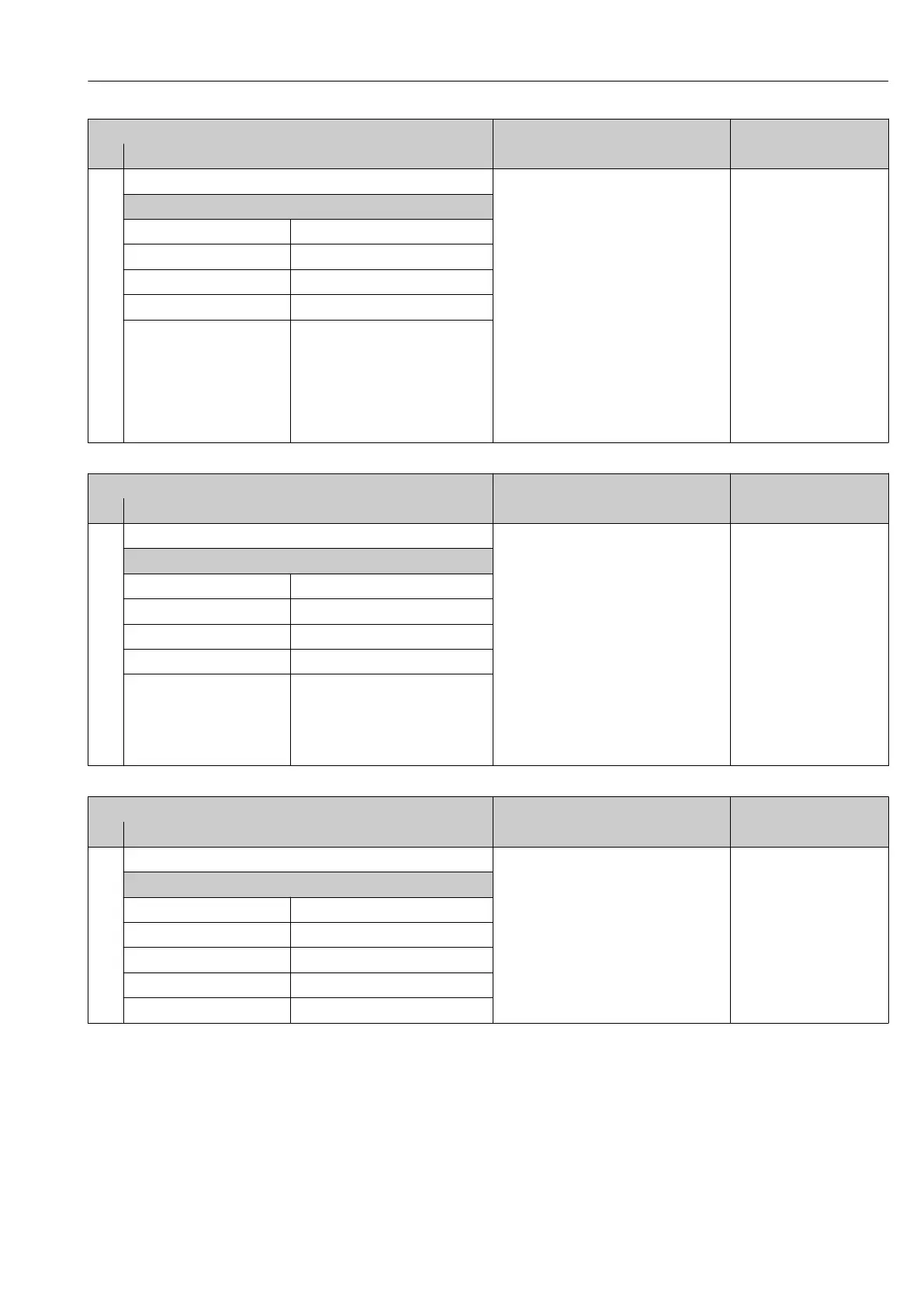

Diagnostic information Remedy instructions Influenced measured

variables

No. Short text

539 Flow computer configuration incorrect 1. Check input value (pressure,

temperature)

2. Check allowed values of the medium

properties

• Calculated saturated

steam pressure

• Density

• Energy flow

• Flow velocity

• Heat flow difference

• Low flow cut off

• Mass flow

• Total mass flow

• Switch output status

• Pressure

• Reynolds number

• Specific volume

• Corrected volume flow

• Steam quality

• Degrees of superheat

• Volume flow

Measured variable status

Quality Bad

Quality substatus Function check

Coding (hex) 0x3C to 0x3F

Status signal S

Diagnostic behavior Alarm

Diagnostic information Remedy instructions Influenced measured

variables

No. Short text

540 Flow computer configuration incorrect Check entered reference value using the

document Operating Instructions

• Calculated saturated

steam pressure

• Density

• Energy flow

• Heat flow difference

• Low flow cut off

• Mass flow

• Total mass flow

• Switch output status

• Pressure

• Reynolds number

• Specific volume

• Corrected volume flow

• Steam quality

• Degrees of superheat

Measured variable status

Quality Good

Quality substatus Function check

Coding (hex) 0xBC to 0xBF

Status signal S

Diagnostic behavior Warning

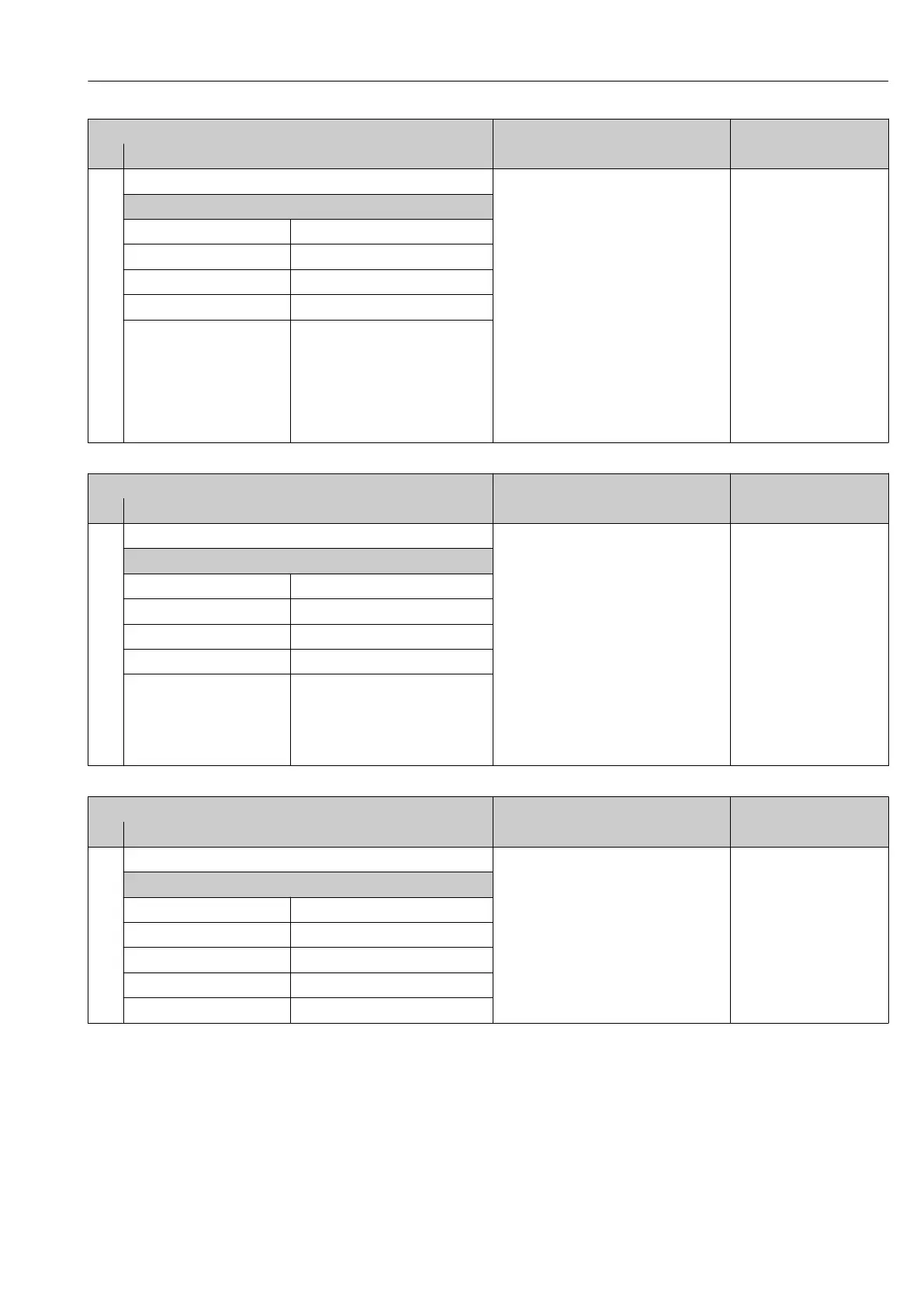

Diagnostic information Remedy instructions Influenced measured

variables

No. Short text

570 Inverted delta heat Check configuration of mounting location

(parameter Installation direction)

Heat flow difference

Measured variable status

Quality Bad

Quality substatus Function check

Coding (hex) 0x3C to 0x3F

Status signal F

Diagnostic behavior Alarm

Loading...

Loading...