Proline Prowirl F 200 PROFIBUS PA Technical data

Endress+Hauser 185

– Heat flow difference

– Specific volume

– Degrees of superheat

Order code for "Sensor version", option "Mass flow (integrated temperature measurement)"

combined with order code "Application package", EU "Wet steam measurement":

• Steam quality

• Total mass flow

• Condensate mass flow

Calculation of the measured variables

The meter electronics system of the Prowirl 200 unit with the order code "Sensor version",

option 3 "Mass flow (integrated temperature measurement)" has a flow computer. This

computer can calculate the following secondary measured variables directly from the

primary measured variables recorded using the pressure value (entered or external) and/or

temperature value (measured or entered).

Mass flow and corrected volume flow

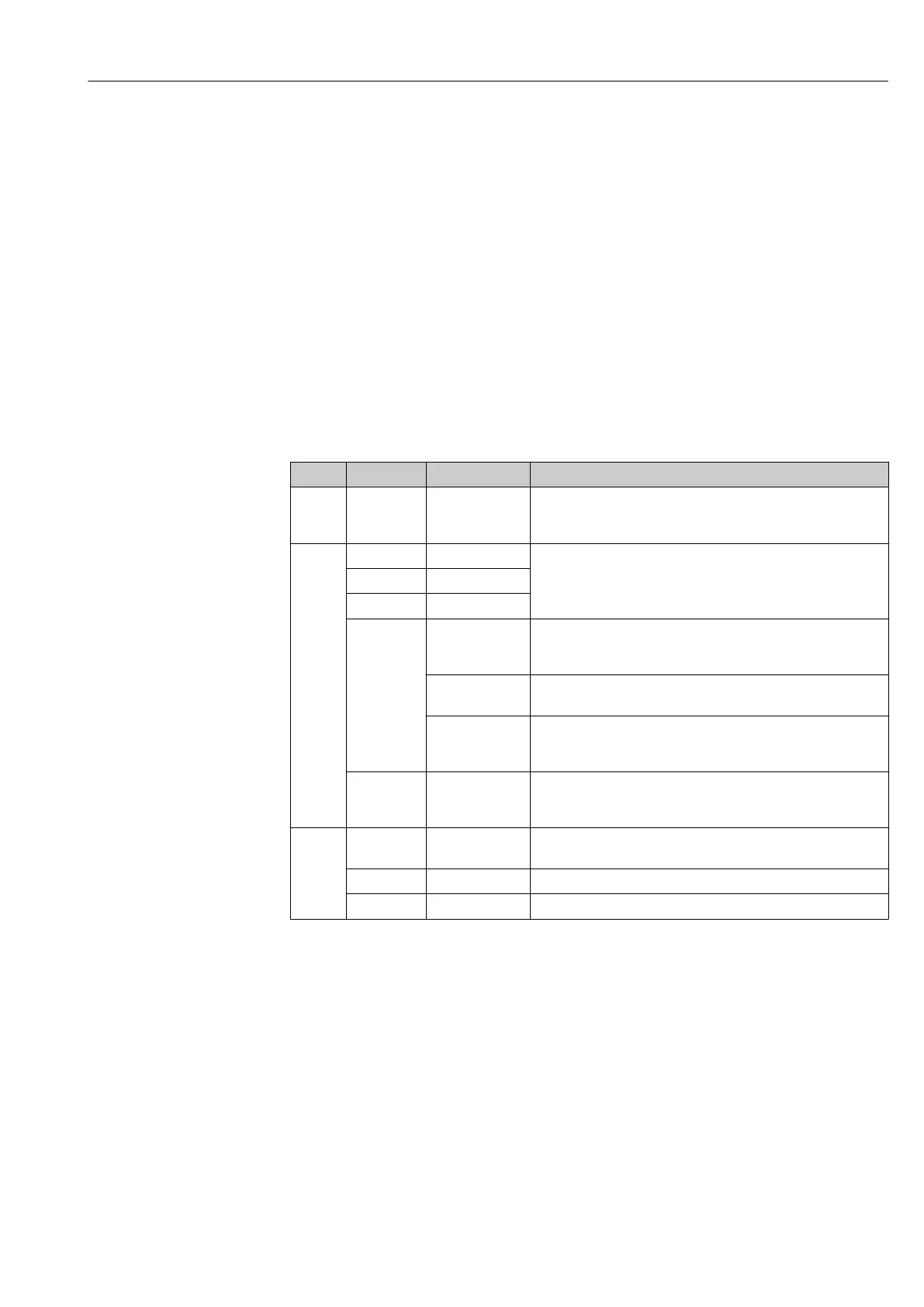

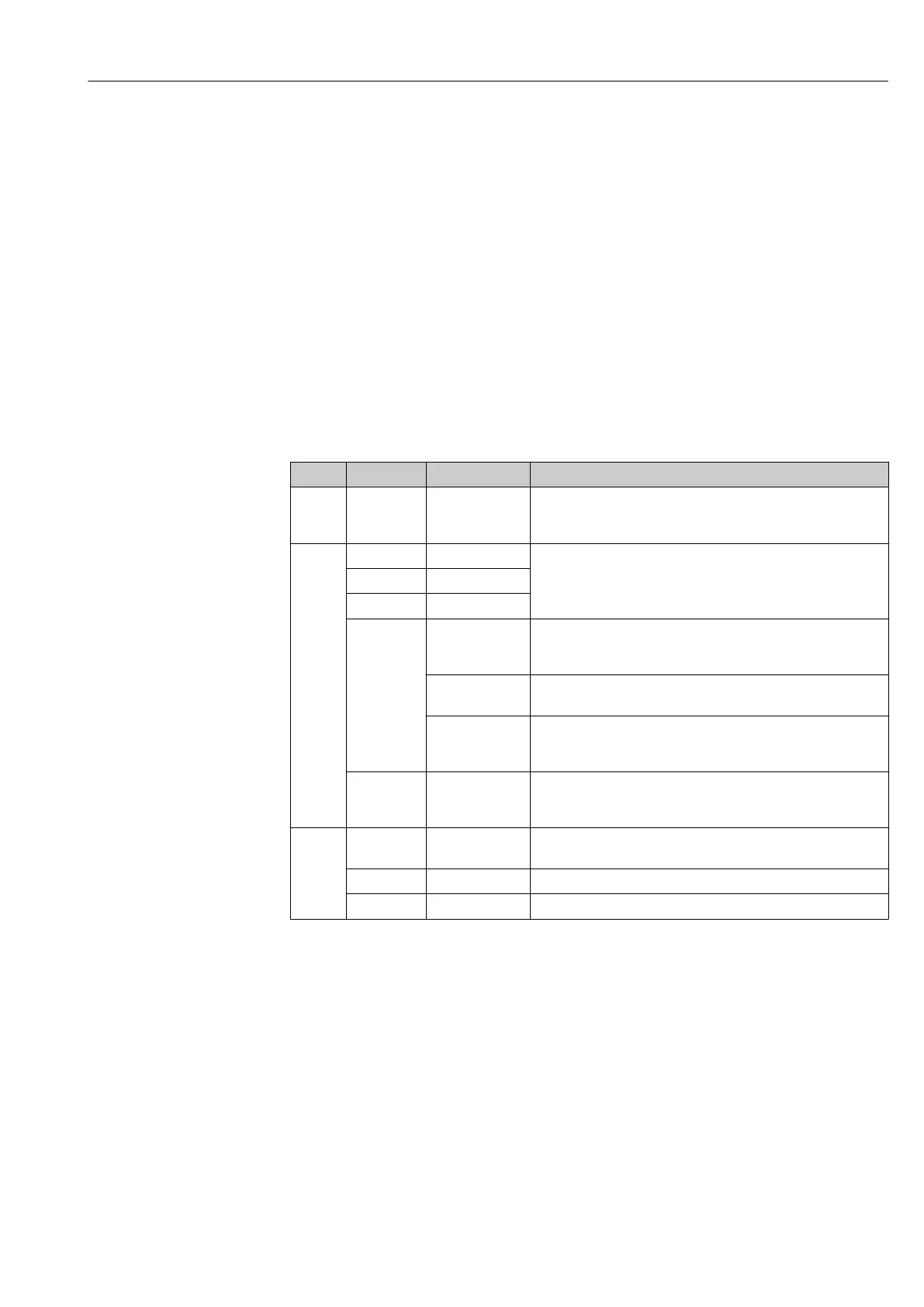

Medium Fluid Standards Explanation

Steam

1)

–

IAPWS-IF97/

ASME

If integrated temperature measurement is provided and the

process pressure is fixed, or if the pressure is read in via

PROFIBUS PA

Gas

Single gas NEL40 If the process pressure is fixed, or if the pressure is read in via

PROFIBUS PA

Gas mixture NEL40

Air NEL40

Natural gas ISO 12213-2 Contains AGA8-DC92

If the process pressure is fixed, or if the pressure is read in via

PROFIBUS PA

AGA NX-19 If the process pressure is fixed, or if the pressure is read in via

PROFIBUS PA

ISO 12213-3 Contains SGERG-88, AGA8 Gross Method 1

If the process pressure is fixed, or if the pressure is read in via

PROFIBUS PA

Other gases Linear equation Ideal gases

If the process pressure is fixed, or if the pressure is read in via

PROFIBUS PA

Liquids

Water IAPWS-IF97/

ASME

Liquefied gas Tables Propane and butane mixture

Other liquid Linear equation Ideal liquids

1) The Prowirl 200 is able to calculate the volume flow, and other measured variables derived from the

volume flow, across all steam types with full compensation using the pressure and temperature. For

information on setting the device behavior, see the "Perform external compensation" section → 101

Mass flow calculation

Volume flow × operating density

• Operating density for saturated steam, water and other liquids: depends on the

temperature

• Operating density for superheated steam and all other gases: depends on the

temperature and process pressure

Loading...

Loading...