DSG-423 FUEL SYSTEM

04-28

The pinpoint tests below should be performed after the

preliminary tests and “Engine Cranks but Will Not

Start” chart Steps 1-3. Any electrical diagnostics should

have been performed to eliminate any sensor, GCP or

solenoid valve problems before proceeding.

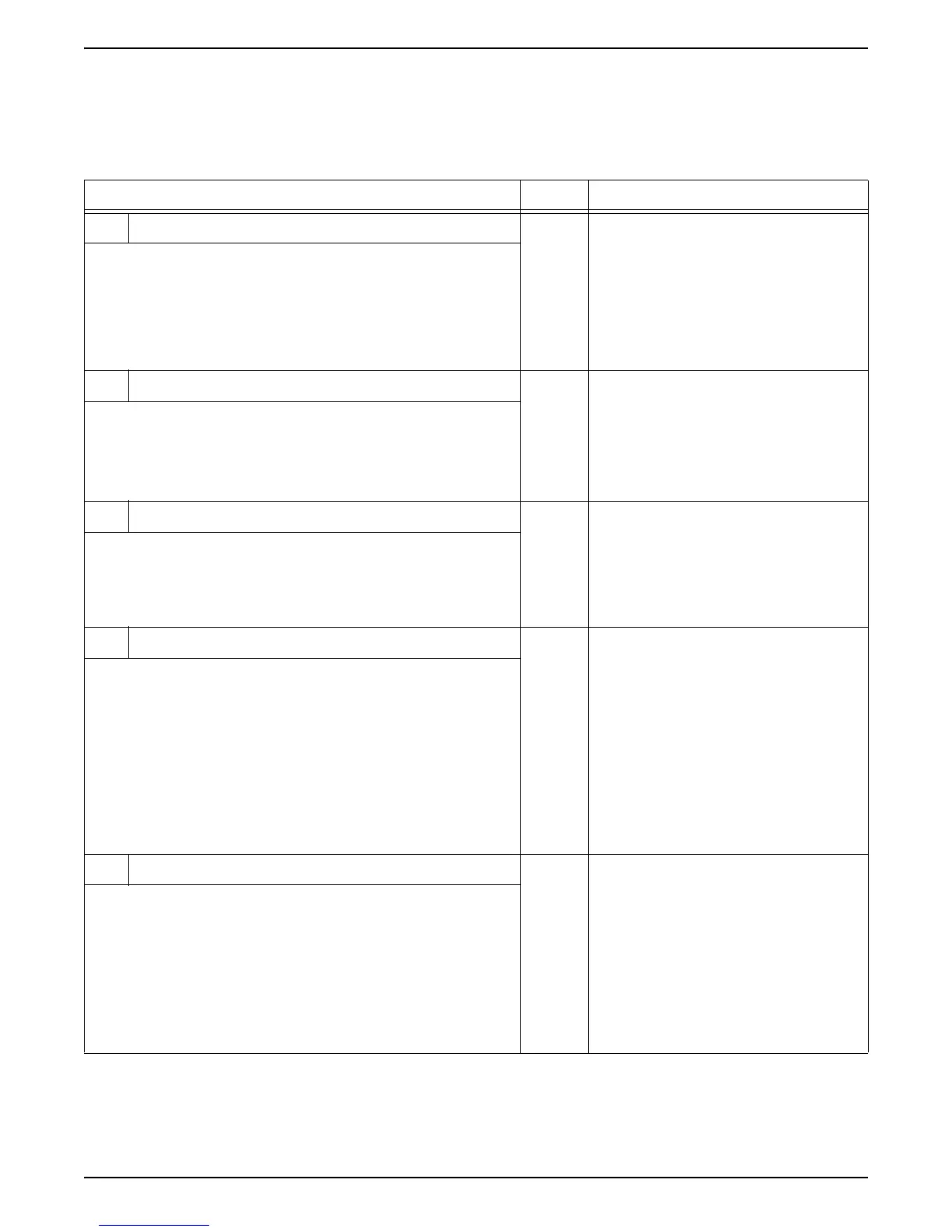

Engine Stops Running - Dies

Test Step Result Action to Take

1 Check for icing or freezing of the regulator. Yes

No

The presence of ice on the converter,

with the engine running, indicates the

possibility of a coolant supply problem.

Check Coolant level and the coolant

system for leaks. Check for proper

coolant type.

Go to Step 2.

• With the Engine at Idle.

• Check for ice or frost build up on the converter casing and

outlet port.

Is ice present?

2 Check FCV vacuum fitting bypass port. Yes

No

Clean out bypass with a .050 size pin

or drill bit and retest.

CAUTION: Do not enlarge the by-

pass port.

Go to Step 3.

• The bypass port is located on the back of the 90 degree

elbow which connects the vacuum line from the converter

to the FCV valve.

Is this bypass partially closed with dirt or debris?

3 Check regulator fuel supply. Yes

No

The fuel filter may be restricting flow or

the fuel lock may be intermittent. Go

to Step 4.

Go to Step 5.

• Using Woodward WTK-1 test kit, install the primary

pressure gauge as described in section 475G-1.

• Start the engine to induce the failure.

Is the primary pressure less than "X" psi or fluctuating?

4 Check fuelock supply voltage. Yes

No

12 volt fuelock activation circuit is

open, shorted to ground or the GCP

module is faulty. Check wiring,

connectors and fuses for possible

cause.

Fuel filter element may be clogged,

inspect and/or replace the fuel filter as

described in section 475F-1. Repeat

test Step 3, if pressure is still less than

specified replace the fuel lock and re-

test before moving to Step 5.

• Key OFF.

• Disconnect Fuelock connector from harness.

• Key ON.

• Using a high impedance DVOM, check for 12 volt supply

at the harness connector.

Is the voltage less than 11.5 volts?

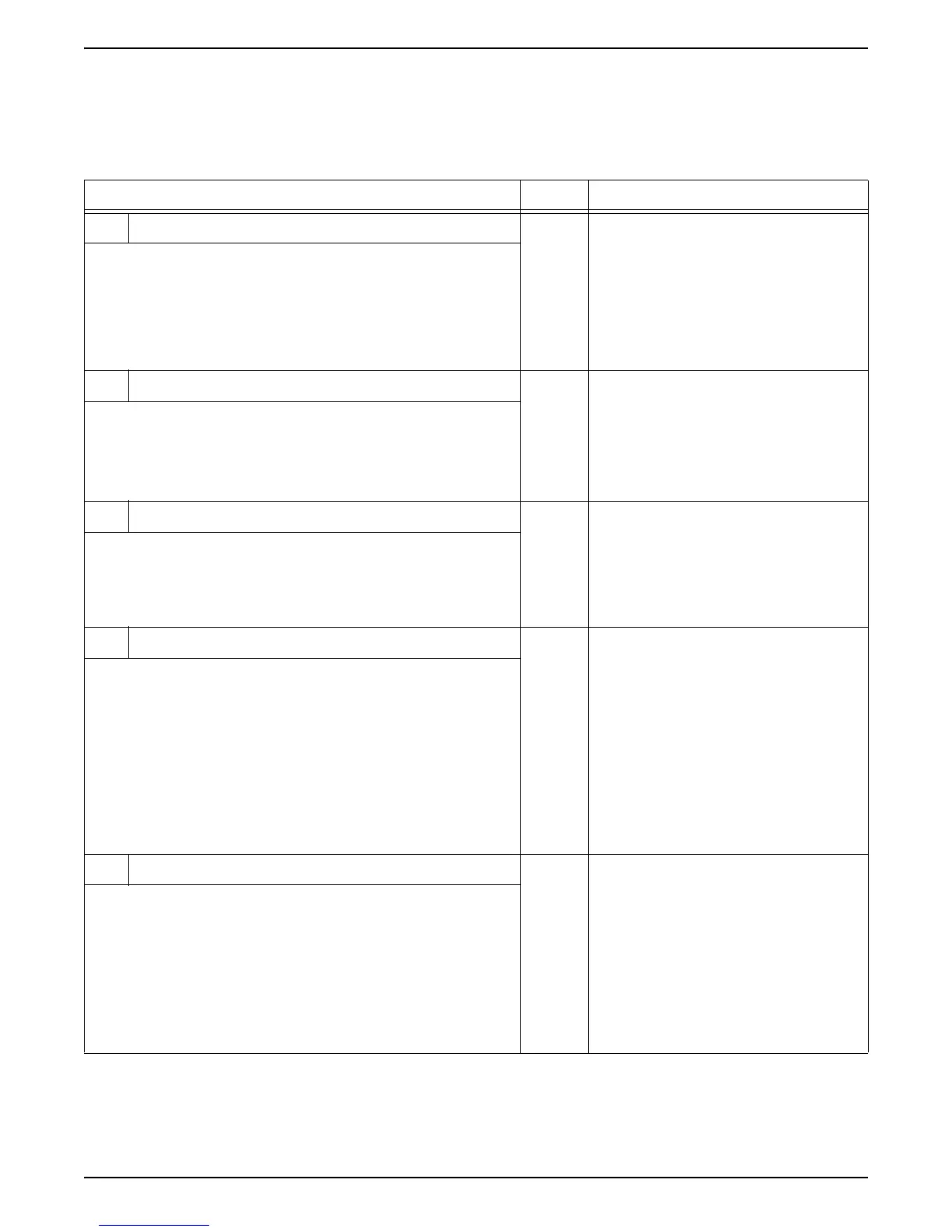

5 Check regulator operation. Yes

No

The Regulator is functioning properly

and the problem may be with the FCV

valve, vacuum hoses or carburetor.

Go to Step 6.

The Regulator is malfunctioning. See

section 475R-1 for service of the

regulator. Repair or replace as

necessary.

• Using Woodward WTK-1 secondary pressure gauge as

described in section 475G-1. (note: the secondary spring

color and pressure range)

• Remove the vacuum hose from the FCV valve to the

regulator.

• Start the engine.

Is the pressure constant and at -1.5 inches of w.c. as

specified?

Loading...

Loading...