100i / 200i / 300i / 400i

86 OPERATION Manual PN: 0560956430

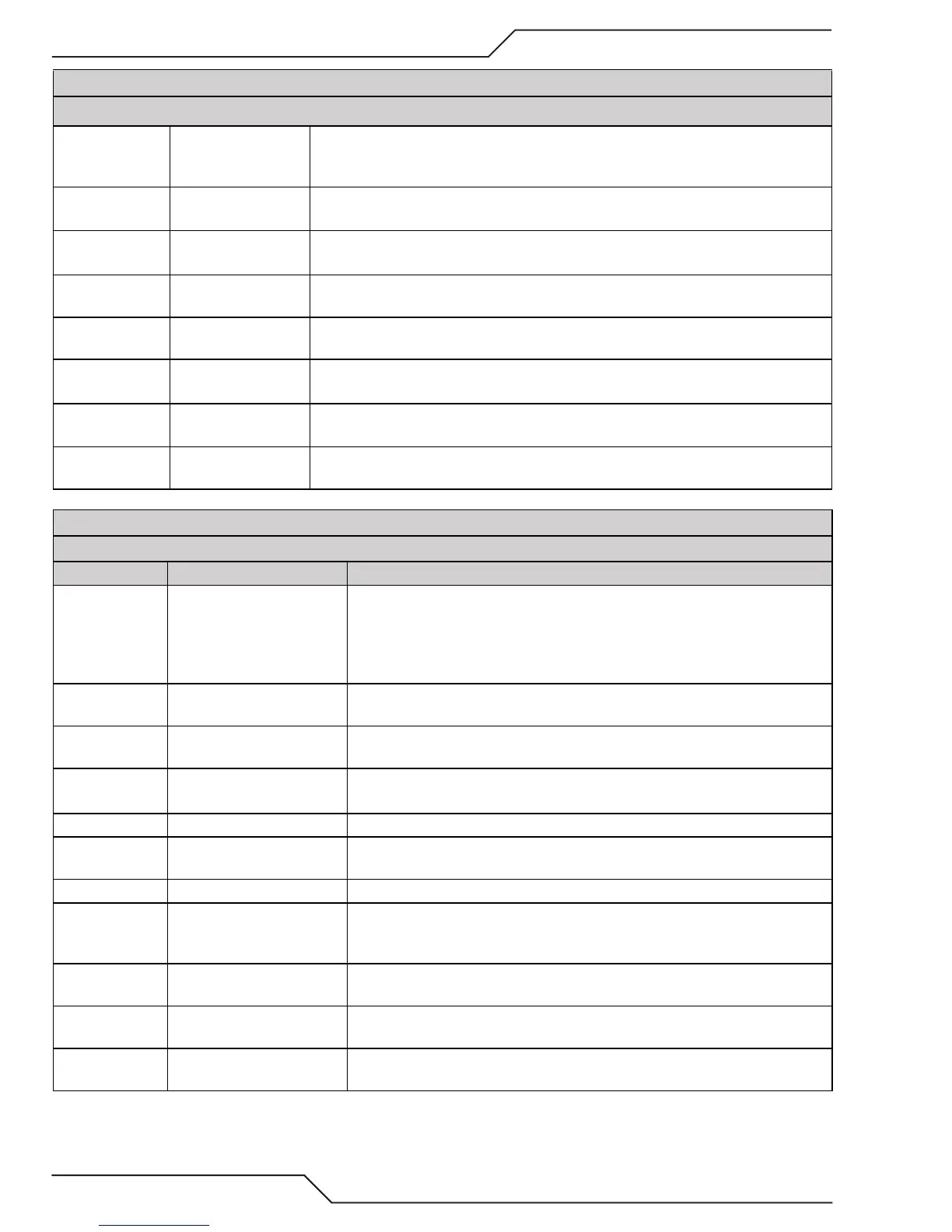

CCM Status Code

Group 2 -- Plasma Power Supply

264

Inverter 3B Over Temp

Ambient

Inverter circuitry is over temperature likely cause is ambient greater than 40 deg

C; Reduce power supply cutting Duty Cycle; Reduce ambient air temperature; Add

auxiliary cooler.

265

Inverter 1A No Input

Power

Inverter section may have no input power. Contactor W1 not closed; Defective con-

tactor or CB4 tripped; Inverter section input not connected; Defective Inverter.

266

Inverter 1B No Input

Power

Inverter section may have no input power. Contactor W1 not closed; Defective con-

tactor or CB4 tripped; Inverter section input not connected; Defective Inverter.

267

Inverter 2A No Input

Power

Inverter section may have no input power. Contactor W1 not closed; Defective con-

tactor or CB4 tripped; Inverter section input not connected; Defective Inverter.

268

Inverter 2B No Input

Power

Inverter section may have no input power. Contactor W2 not closed; Defective con-

tactor or CB4 tripped; Inverter section input not connected; Defective Inverter.

269

Inverter 3A No Input

Power

Inverter section may have no input power. Contactor W2 not closed; Defective con-

tactor or CB4 tripped; Inverter section input not connected; Defective Inverter.

270

Inverter 3B No Input

Power

Inverter section may have no input power. Contactor W2 not closed; Defective con-

tactor or CB4 tripped; Inverter section input not connected; Defective Inverter.

271

Inverter ID reading

fault

CCM found ID values inconsistant during reading. CCM to an Inverter section rib-

bon damaged or disconnected; Inproper ribbon cable routing.

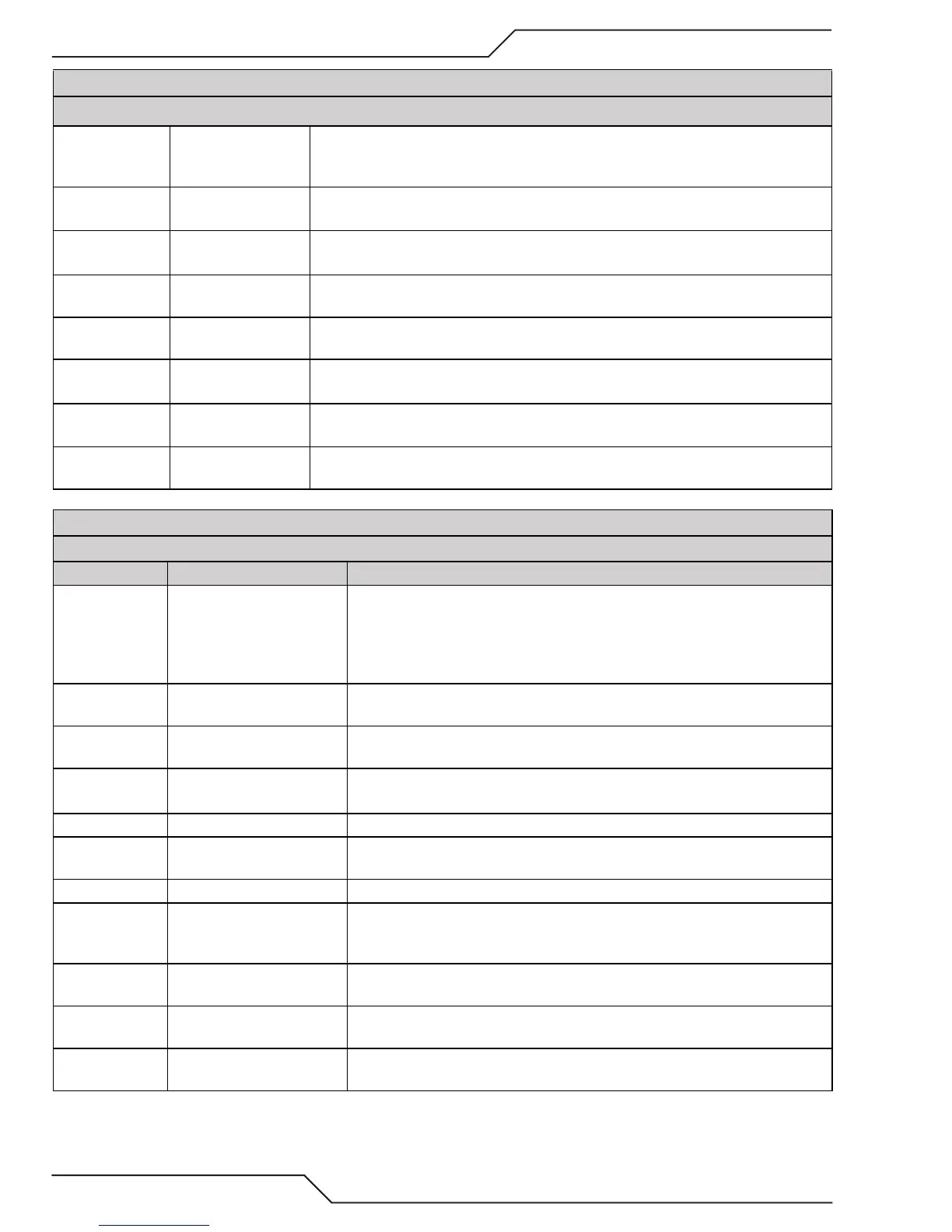

CCM Status Code

Group 3 -- Gas Controller Status & Protocol

Code Message Remedy / Comments

301/302

Gas Control communication

or reply fault

Problem with fiber optic cable to Gas Selection Console or Gas Control Unit;

Dirt on fiber ends or in connectors; blow out with clean dry air. Fiber not

locked into connector; Sharp bends in fiber cable; Fiber defective; Gas Se-

lection Console or Gas Control Unit power supply defective; Gas Selection

Console or Gas Control Unit circuit board defect

303

Gas Supply Pressure out of

range.

Inlet plasma or shield pressure low or defective pressure sensors PS3 & PS4;

For Automatic Gas Control see Gas Control Unit for pressure faults.

304 Gas Control Purging

Normal following power up or returning from Plasma Disable. Wait for purge

to finish.

305 Gas Control protocol error

Verify Firmware revision for compatibility with Gas Selection Console and Gas

Control Unit.

306 Not used Reserved for other future use.

307

Gas Control sequencing

error

Verify Firmware revision for compatibility with Gas Selection Console and Gas

Control Unit

308 Gas Control Type Mismatch Wrong CCM for Power Supply; Install correct CCM

309 Gas Control command fault

Verify Firmware revision for compatibility with Gas Selection Console and Gas

Control Unit; Electromagnetic interference with Arc Starter; inspect grounding;

bonding; and isolation

310 * Gas Control Unit fault

Check Gas Control Unit status indicator for specific problem

311 *

Gas Control Unit valve con-

trol fault Check Gas Control Unit status indicator for specific problem

312 * Gas Selection Console fault

Check Gas Selection Console status indicator for specific problem

Loading...

Loading...