100i / 200i / 300i / 400i

Manual PN: 0560956430 OPERATION 87

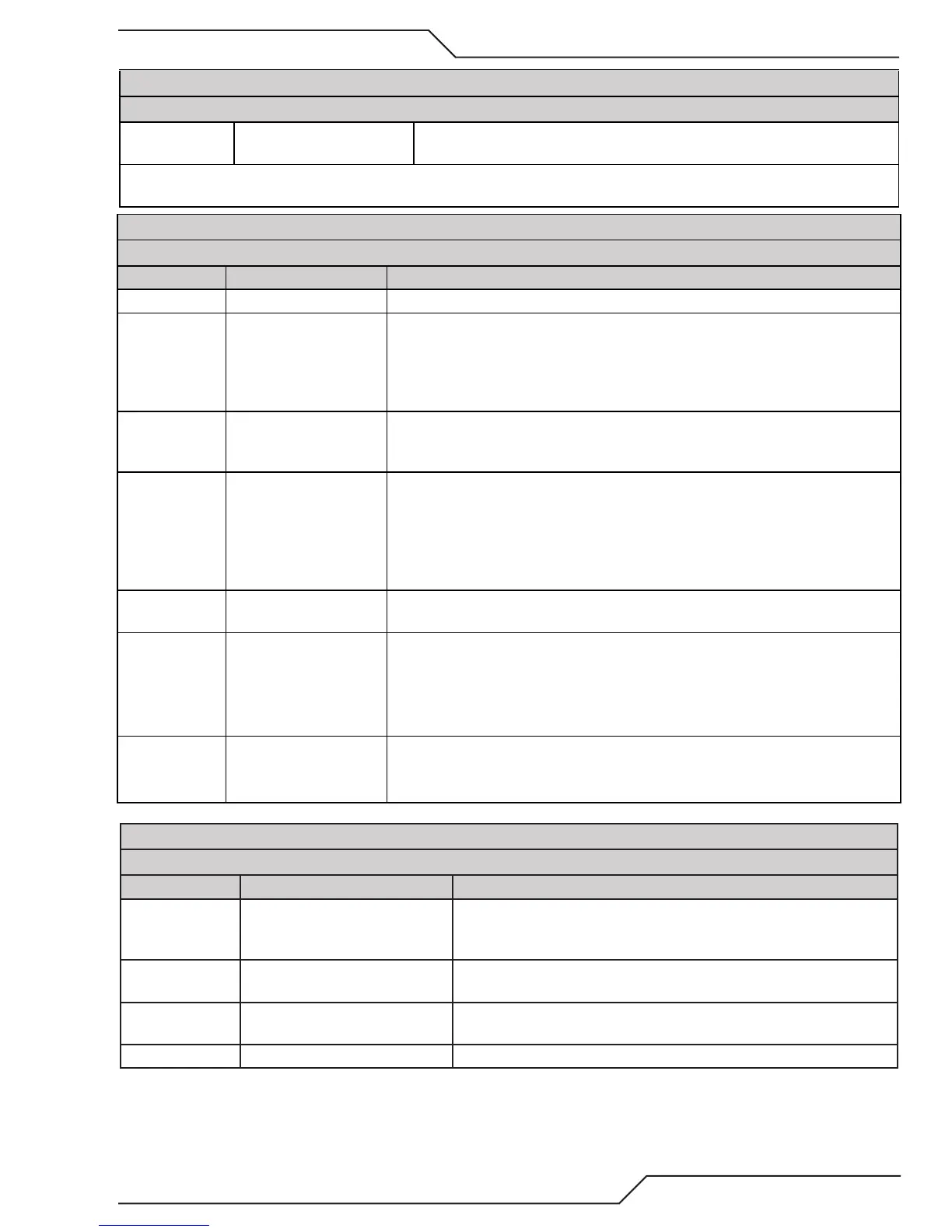

CCM Status Code

Group 3 -- Gas Controller Status & Protocol

313 *

Gas Controller not config-

ured.

Gas Selection Console or Gas Control Unit not configured for a process or

locked; See Gas Selection Console and Gas Control Unit status

* Applies to Automatic Gas Control 3000 (Auto Gas) only

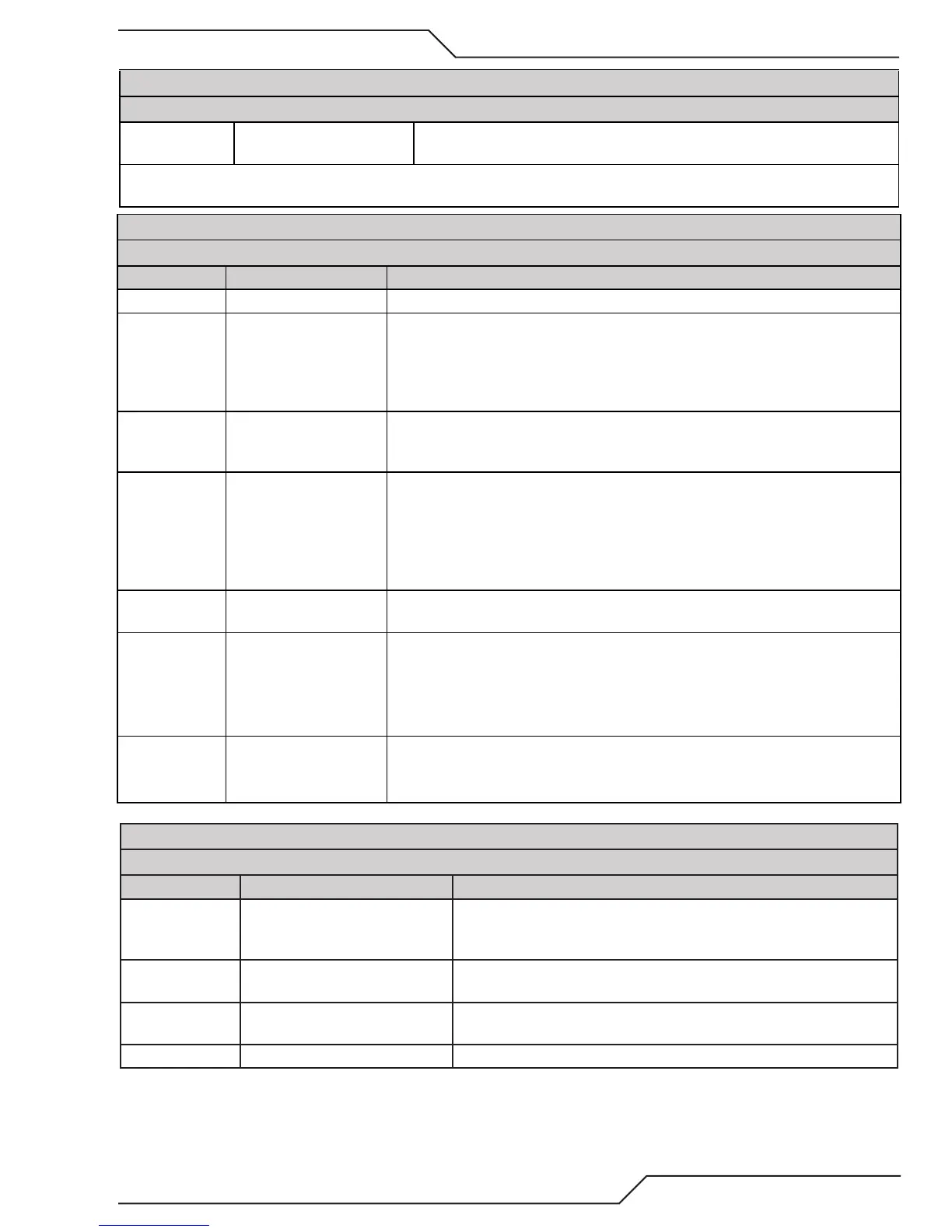

CCM Status Code

Group 4 -- Torch Coolant System

Code Message Remedy / Comments

401 Coolant Level low Check coolant level, add as needed. Defective or disconnected level sensor.

402

Low coolant flow

Coolant flow as measured by flow switch FS1 is less than 0.7 gpm; Clogged filter;

Restriction in torch lead or head; Wrong style consumables; Bad O-ring on the

torch check valve; broken or defective torch coolant tube/check valve; Defec-

tive pump or bypass valve. 402 code along with 104 code is probably a low flow

problem.

403

Coolant overheated

Coolant supply temperature exceeded 75 degrees Celcius (167F). Operating with

side panel loose or removed; Air flow blocked at air inlet or exit of power supply;

Coolant fan failed; radiator fins clogged with dirt.

404

Coolant System not

ready.

Proper coolant flow of 0.7 gpm as measured by flow switch FS1 was not obtained

during up to 4 minutes of Priming. New installation can require additional Priming

cycle(s) to fill hoses with coolant; cylce power to restart Priming; Coolant hoses

or torch hoses reversed; Clogged coolant filter; Restriction in torch lead or head;

Wrong style consumables; broken or defective torch coolant tube/check valve;

Defective or disconnected FS1 flow SW; Defective pump or bypass valve.

405

Low Coolant Level

Warning

Low coolant level during cut, does not stop cut. Add coolant as required.

406

Coolant Flow Low

Warning

This is a warning, does not stop system operation. Coolant flow rate lower than ex-

pected. Can be caused by gas bubbles being introduced into the coolant or wrong or

mismatched or worn consumable parts; Failed seals in torch cartridge or torch body;

Clogged coolant filter; Restriction in torch lead or head; defective or disconnected

FL1 flow sensor.

407

Coolant overheated, high

ambient.

Coolant supply temperature exceeded 75 degrees Celsius (167 Fahrenheit) likely

cause ambient greater than 40 degrees Celsius (104 Fahrenheit); Reduce cutting

duty cycle; Reduce ambient temperature; Add separate coolant cooler.

CCM Status Code

CCM-Group-5 Gas Controller Communication Port

Code Message Remedy / Comments

501 CANBUS Acknowledge Fault CCM to Gas Selection Console Fiber-optic control cable not connected,

not properly connected or cable defective. Gas Selection Console’s

power supply or Control PCB defective. Defective CCM, replace.

502 CANBUS Off Dirt on fiber ends or in connectors; blow out with clean dry air; Fiber

not locked into connector; Sharp bends in fiber; Fiber defective

503 CANBUS Errors Warning Dirt on fiber ends or in connectors; blow out with clean dry air; Fiber

not locked into connector; Sharp bends in fiber; Fiber defective;

504 Reserved No information available; Contact customer service

Loading...

Loading...