Chapter 6 Fastening Operation

PAGE 6-30

•If the rate start torque (angle) cannot be detected during fastening operation, the rate judgment

will not be performed.

•Under the following conditions, the torque (angle) at the end of fastening is judged as the rate

end torque (angle).

•If the set values are set so that rate start torque (angle) > rate end torque (angle).

•If the rate end torque (angle) cannot be detected during the fastening operation.

. When the increase in angle from the measurement start point to the end point is “0” deg, the

operation varies depending on the firmware version.

·Before ver1.304: The rate calculation becomes "0" and rate is not judged

·Ver1.305 or later: The rate calculation becomes the maximum and the rate judgment is rate

high NG

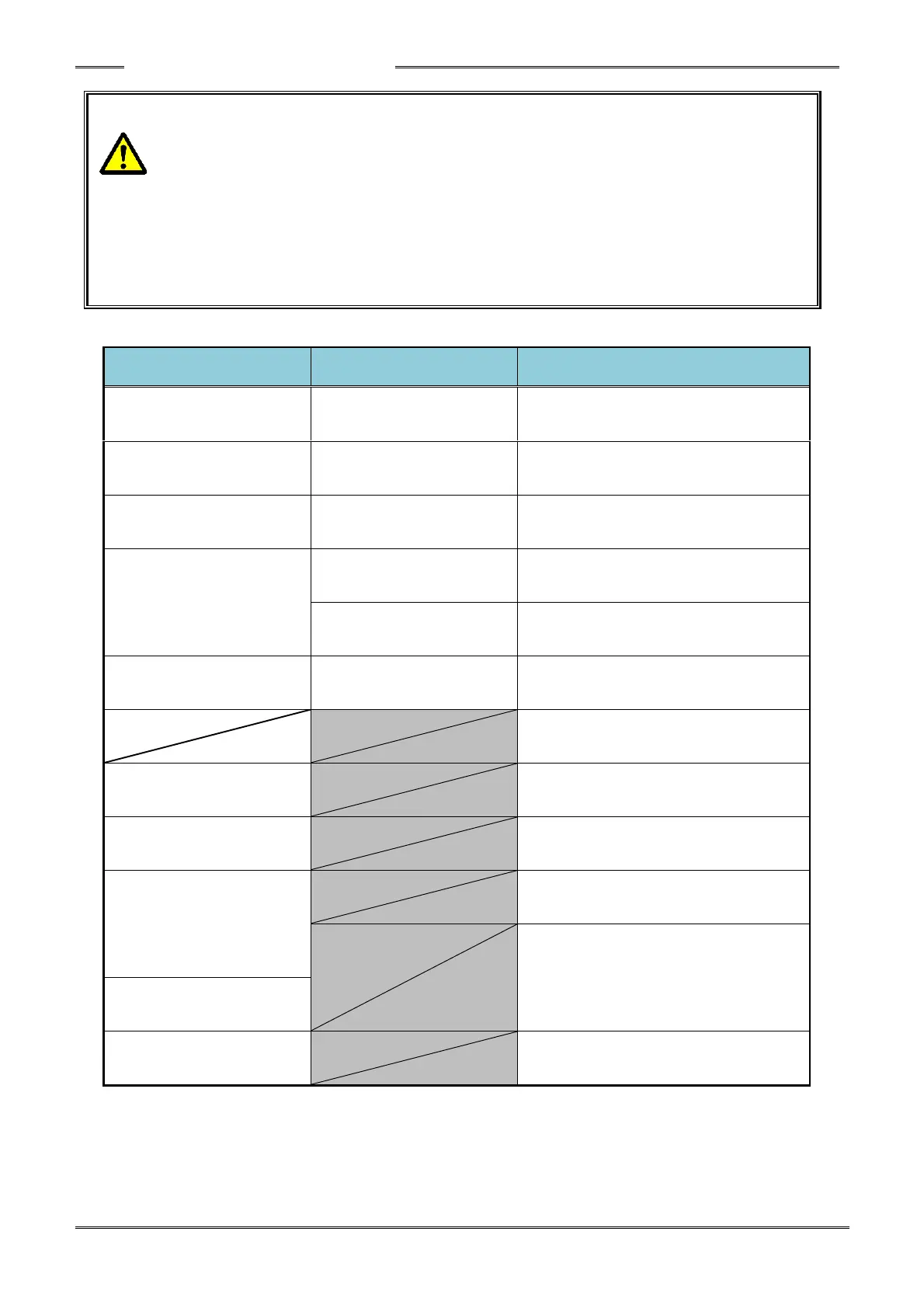

●FUSION/HFC3000 Fastening Parameter (Rate) Correspondence Table

FUSION

Fastening Parameter

HFC3000

Fastening Parameter

The torque value sets the start point of

measurement of torque rate 1.

15 1st Torque

(1st Rate End Torque)

The torque value sets the end point of

measurement of torque rate 1.

The torque value sets the start point of

measurement of torque rate 2.

18 CROS Torque

(2nd Rate End Torque • 3rd

Rate End Torque)

The torque value sets the end point of

measurement of torque rate 2.

The torque value sets the start point of

measurement of torque rate 3.

13 Standard Torque

(3rd Rate End Torque)

The torque value sets the end point of

measurement of torque rate 3.

The angle value sets the start point of

measurement of torque rate 1.

23 1st Angle

(1st Rate End Angle)

The angle value sets the end point of

measurement of torque rate 1.

The angle value sets the start point of

measurement of torque rate 2.

24 CROS Angle

(2nd Rate End Angle • 3rd Rate

Start Angle)

The angle value sets the end point of

measurement of torque rate 2.

The angle value sets the start point of

measurement of torque rate 3.

22 Standard Angle

(3rd Rate End Angle)

The angle value sets the end point of

measurement of torque rate 3.

Loading...

Loading...