Chapter 3 System Description

PAGE 3-6

3-2 Tools

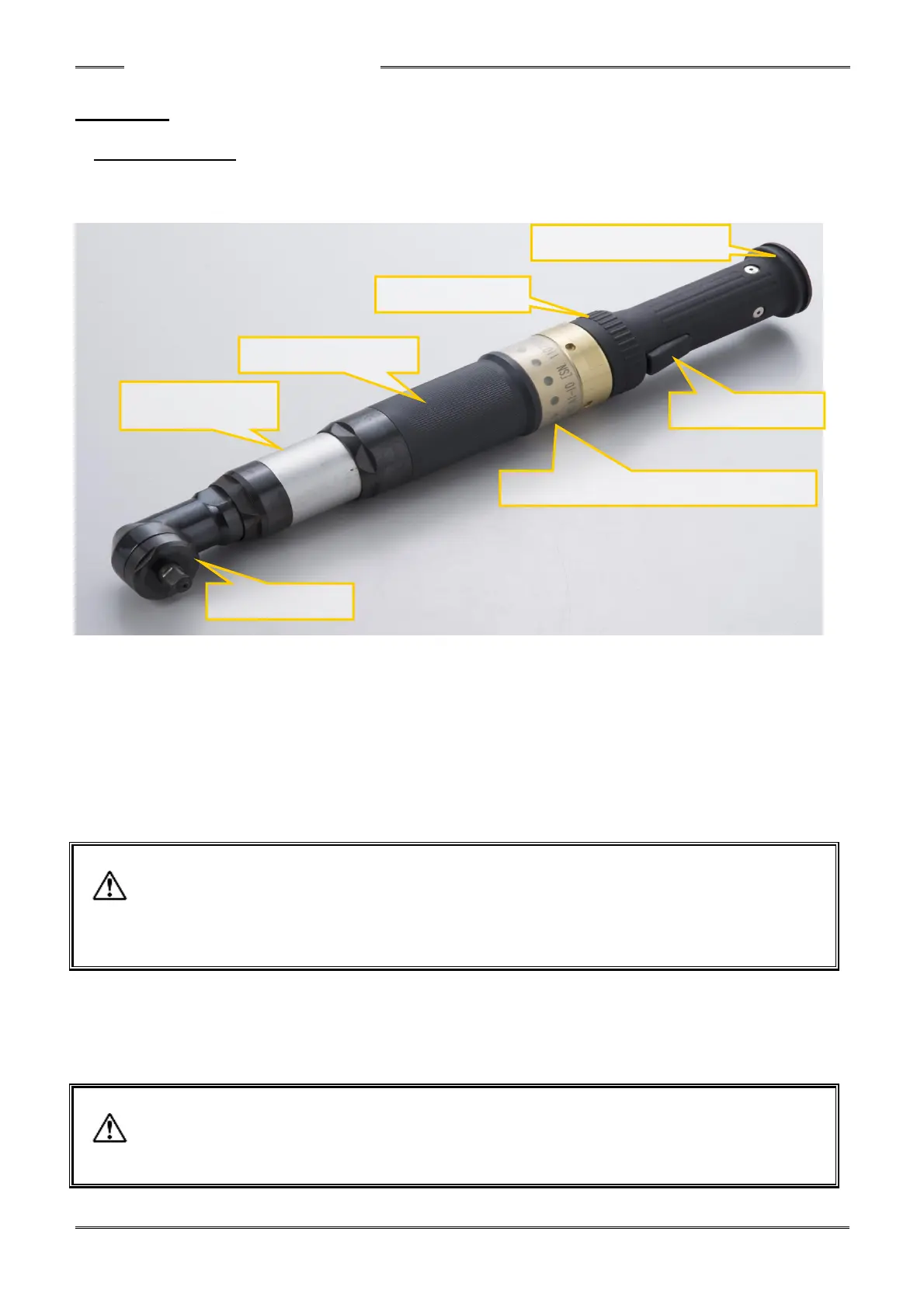

3-2-1 Angle Tool

Right angle hand-held type fastening tool provided with angle head, planetary gear, torque

transducer, servomotor, indicator LEDs, and operating switches.

①Starting switch: When the switch is depressed, the tool (output square drive) rotates for fastening.

When the switch is released (during rotation of the tool), the fastening (rotation)

stops. For normal fastening operation, the start switch must be held until

fastening is completed. (Deadman type operation)

②Reverse switch: Used to switch between normal and reverse rotation direction.

Ring (rotational) type switch – Rotate ring to switch between normal/reverse

operation (*in older models, this is a pushbutton type switch). When the reverse

rotation mode is selected, the judgment LED flashes orange.

When the start switch is turned ON in this state, the reverse (rotation) operation is

performed until the Start switch is released.

* When loosening a fastener that has already been fastened over 5N

・

m, the default

REVERSE HIGH TORQUE LIMIT setting will stop the reverse operation as a safety

precaution.

This can be changed in the setting of the fastening REVERSE HIGH TORQUE LIMIT

parameter. If changed, be careful of torque reaction caused by higher torque.

③ Judgment / Status LED indicators (4 LEDs):

When the fastening result is OK (Accept), the green LED lights.

In the case of TOTAL OK (Total Accept), the green LED flashes.

When the fastening result is NG (Reject), the red LEDs lights.

In the reverse rotation mode and during power up, the orange LED lights.

* When using a tool-hanging clamp around the (Torque transducer/planetary gear area)

ensure the correct selection and do not over-torque the clamp or damage can result.

Over tightening, the clamp can cause deformation of the tool case, affecting the rotation

of the tool and/or accuracy of fastening torque.

Loading...

Loading...