Chapter 6 Fastening Operation

PAGE 6-34

6-5-3 Fastening Speed and Time

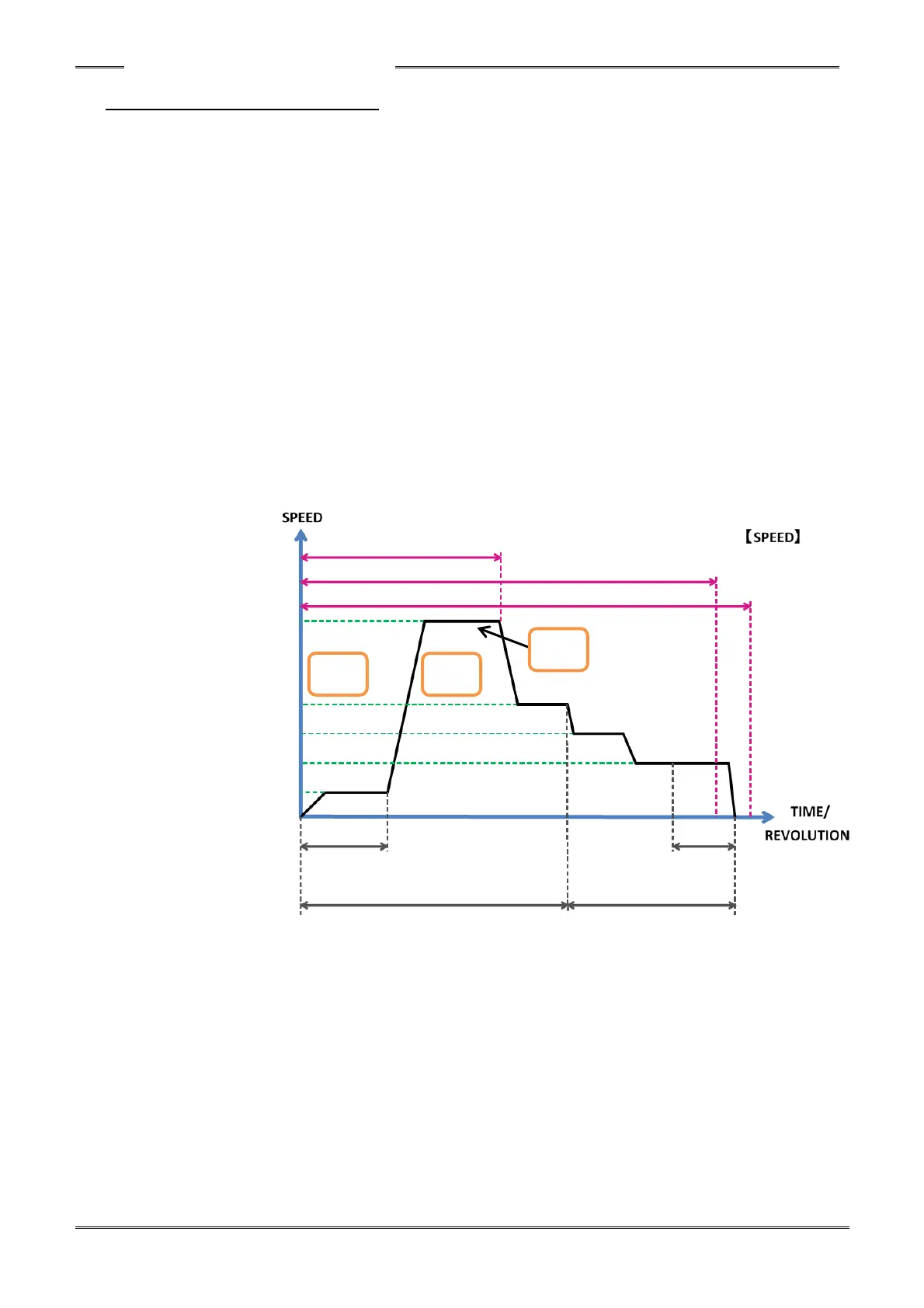

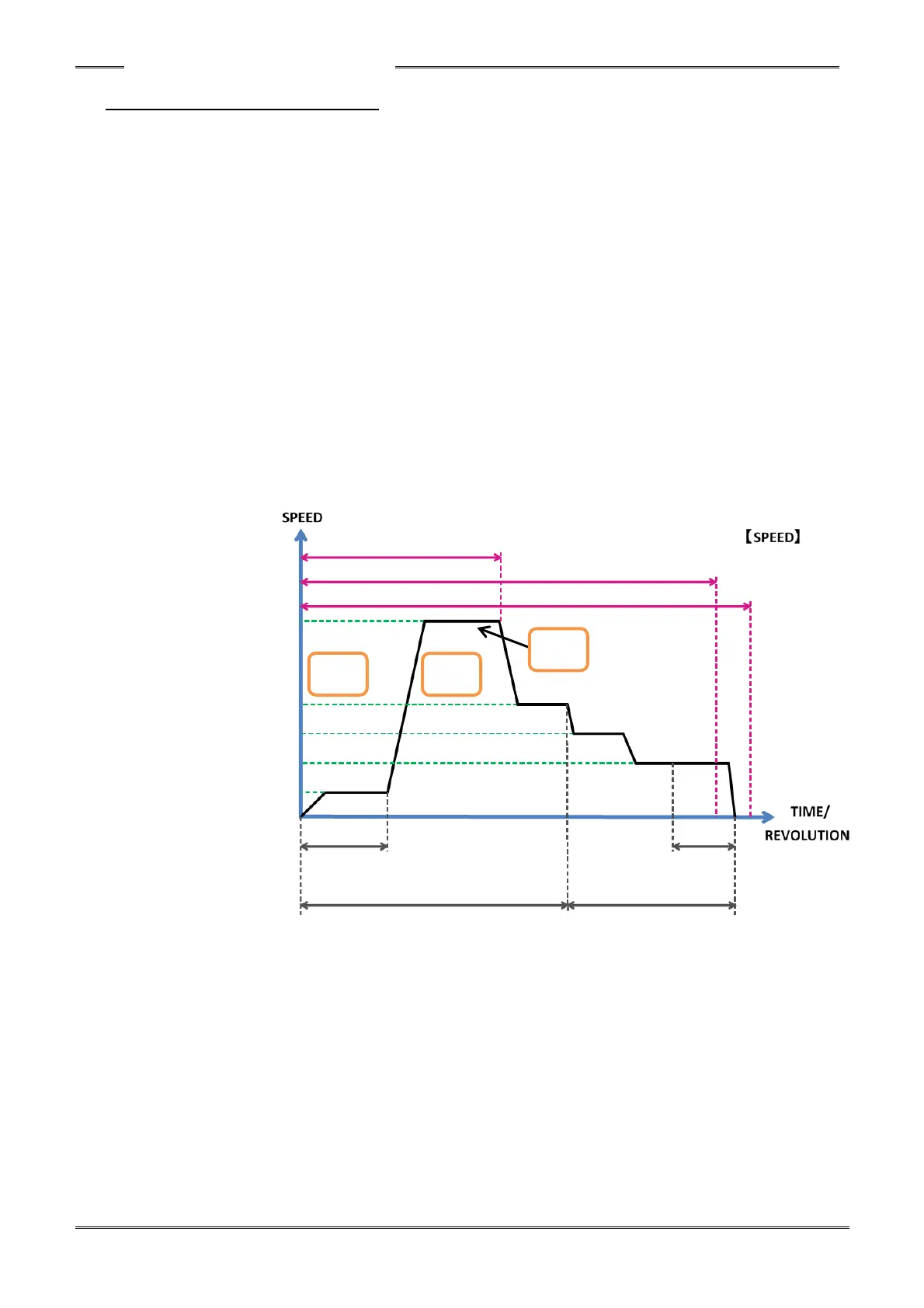

The HFC3000 System is user-programmable for operations involving multiple speed settings. The use of

multiple speeds during the fastening process aids in socket engagement, achieving cycle time and control

ling the applied torque during all stages. Speed functions work the same for Torque Control and Angle C

ontrol using any of the previously stated standard Judge functions. Special conditions that affect these op

erations will be identified in the appropriate section.

1. The system will fasten to the 1

ST

TORQUE/ANGLE value during the specified 1

st

TIME limits. The

following fastening operations occur during 1

st

time:

a) The system starts off running at INITIAL SPEED for the period specified by INITIAL TIME. The

initial time should be set to mitigate shock occurred at the fastening start time or to engage a bolt

and a socket.

b) Upon completion of INITIAL TIME the system switches to FREERUN SPEED for the period

specified by FREERUN REVOLUTIONS. The number of revolutions required to complete

INITIAL TIME will be deducted from the number of revolutions ran at FREERUN SPEED.

c) Once RAMP DOWN START TORQUE is detected or FREERUN REVOLUTIONS expires, the

system will switch from FREERUN SPEED to 1

st

SPEED and continue to fasten until 1

st

TORQUE/ANGLE is attained or the 1ST TIME HIGH LIMIT is reached. 1

st

SPEED is switched

right before the fastener is seated and is intended to provide adequate speed to seat the fastener

without getting a load to the tool.

Loading...

Loading...