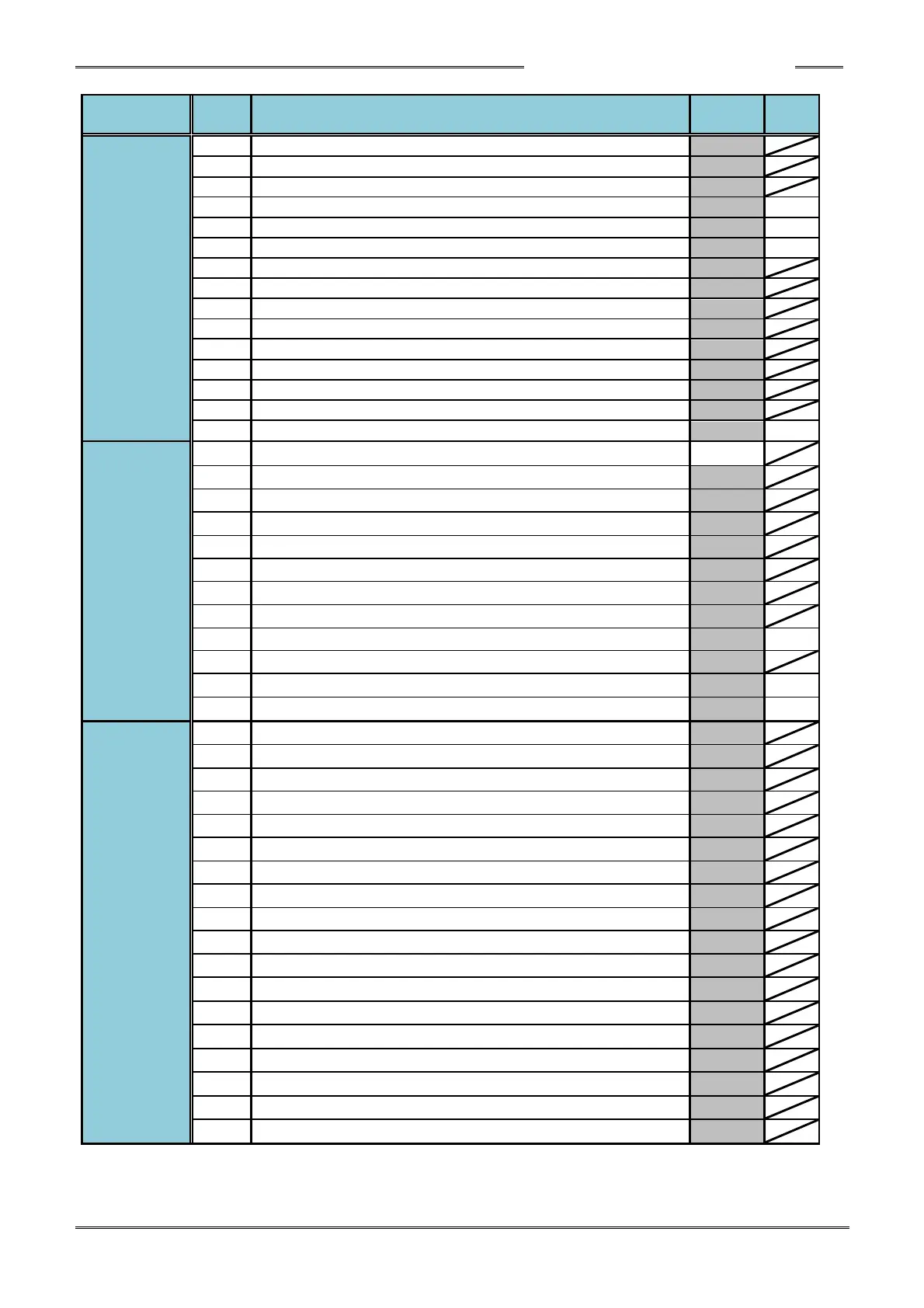

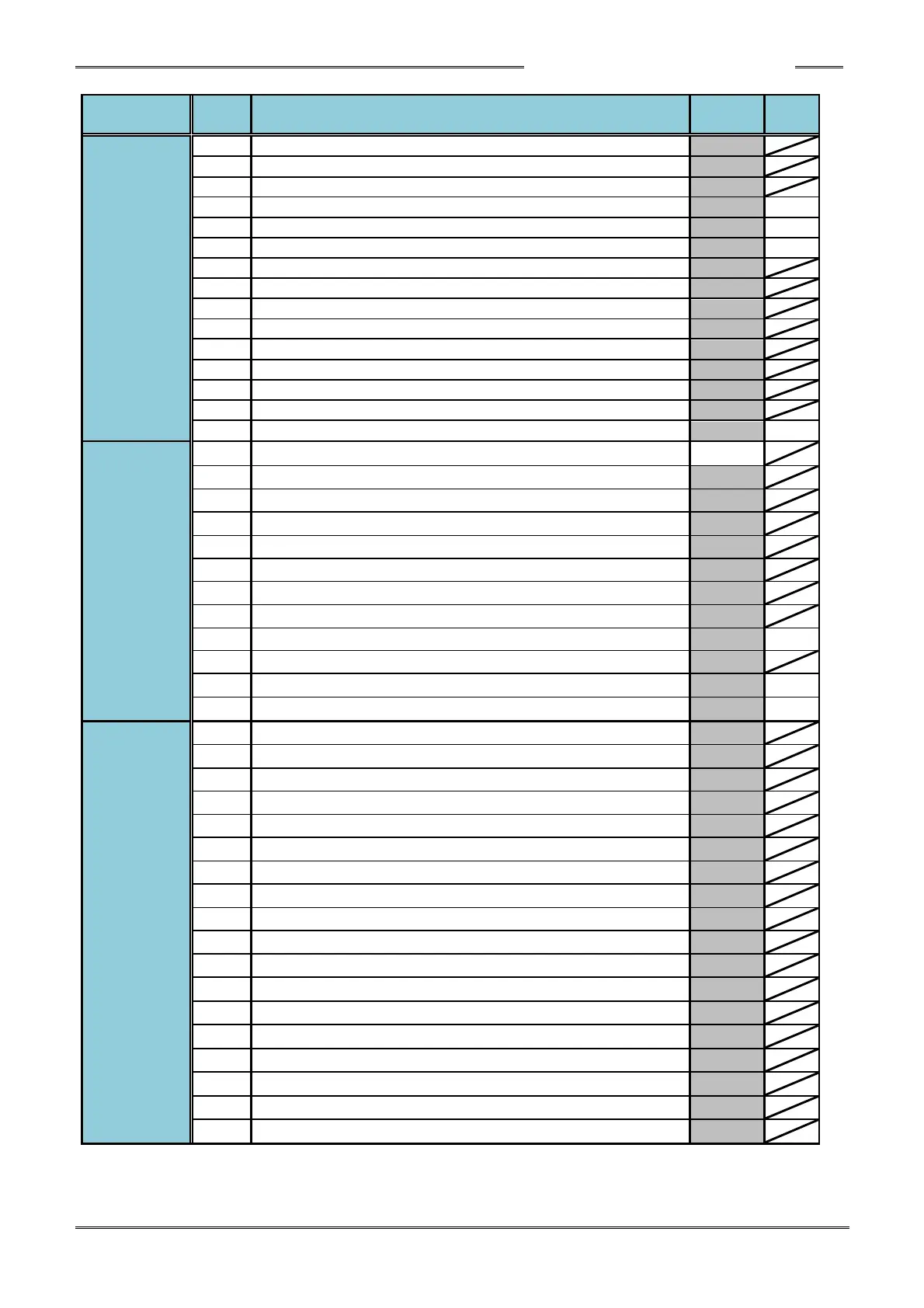

Chapter 6 Fastening Operation

PAGE 6-41

Connected Tool Information “015-P1”

Connected Tool CAL Torque Decimal Point Position

Connected Tool CAL Torque

Connected Tool CAL Voltage

Connected Tool ZERO Voltage

Connected Tool Internal Gear Ratio (×100)

Connected Tool Serial No. (upper 3 digits)

Connected Tool Serial No. (lower 4 digits)

Connected Tool Rotation Direction

Connected Tool Order No. (upper 2 digits)

Connected Tool Order No. (lower 5 digits)

Connected Tool Cycle Count (×1 million)

Connected Tool Cycle Count (×1)

Connected Tool Maximum Current

controller Setting Tool No.

controller Setup Tool Information “015M50”

Parameter Setting File Version

Sequence Setting File Version

PLC Output Layout Setting File Version

Fieldbus Setting File Version

Fieldbus Message Setting File Version

RS232C Input/Output Setting File Version

controller RS232C-1 Communication Speed

controller RS232C-1 Parity

controller RS232C-1 Stop Bit

controller RS232C-1 Word Length

Connected Fieldbus Information

controller Setting Fieldbus Information

Station No. (Node Address) (1 ~ 64 or 0 ~ 63)

Communication Speed (0 ~ 4)

Occupied Stations (1, 2, 3, 4)

Extended Cyclic Setting (1, 2, 4, 8)

I/O Setting Byte Length “PLC → MASTER Axis”

I/O Setting Byte Length “Master Axis → PLC”

Message Block Byte Length

Message Setting Byte Length “PLC → MASTER Axis”

Message Setting Byte Length “Master Axis → PLC”

IP Address (upper 6 digits)

IP Address (lower 6 digits)

Subnet Mask (upper 6 digits)

Subnet Mask (lower 6 digits)

Loading...

Loading...