Chapter 6 Fastening Operation

PAGE 6-9

[Tool Response•St1.] (0~255) Factory Adjustment only

[Tool Response•St2.] (0~15) Factory Adjustment only

[Tool Response•Ad1.] (0~255)

The actual sensing level of the starting trigger switch is indicated.

[Tool Response•Ad2.] (0~255)

The actual sensing level of the F/R slide switch is indicated.

[Tool Response•G. Gyrosensor Shake Detection Angle]

-2048° ~ +2047°

[Tool Command•Ct1.] (0~255) (Factory Adjustment only)

CAL ON, GYRO RESET, etc.

[Tool Command•Ct2.] (0~255) (Factory Adjustment only)

Angle conversion constant (fixed at 67)

[Tool Command•LEd.] (0~255) (Factory Adjustment only)

LED-related command

[Tool Command•BuZ.] (0~255) (Factory Adjustment only)

Buzzer-related command

[Tool Command•Gan. Gyro Restriction Angle] (0~255)

[Fieldbus•Status Monitor•FbS]

Fieldbus connection condition: In the normal state, “4” is indicated.

Any other number indicates a disconnected state (STOP mode is activated and

operation is disabled).

[Angle Head Torque Variation [%]]

Displays the current torque variation rate of the angle head after the fastening

operation.

When the rate exceeds the value set in D-No.541“[Angle Head Torque Variation]”,

A.09-10 “Angle Head Torque Variation Abnormal” occurs.

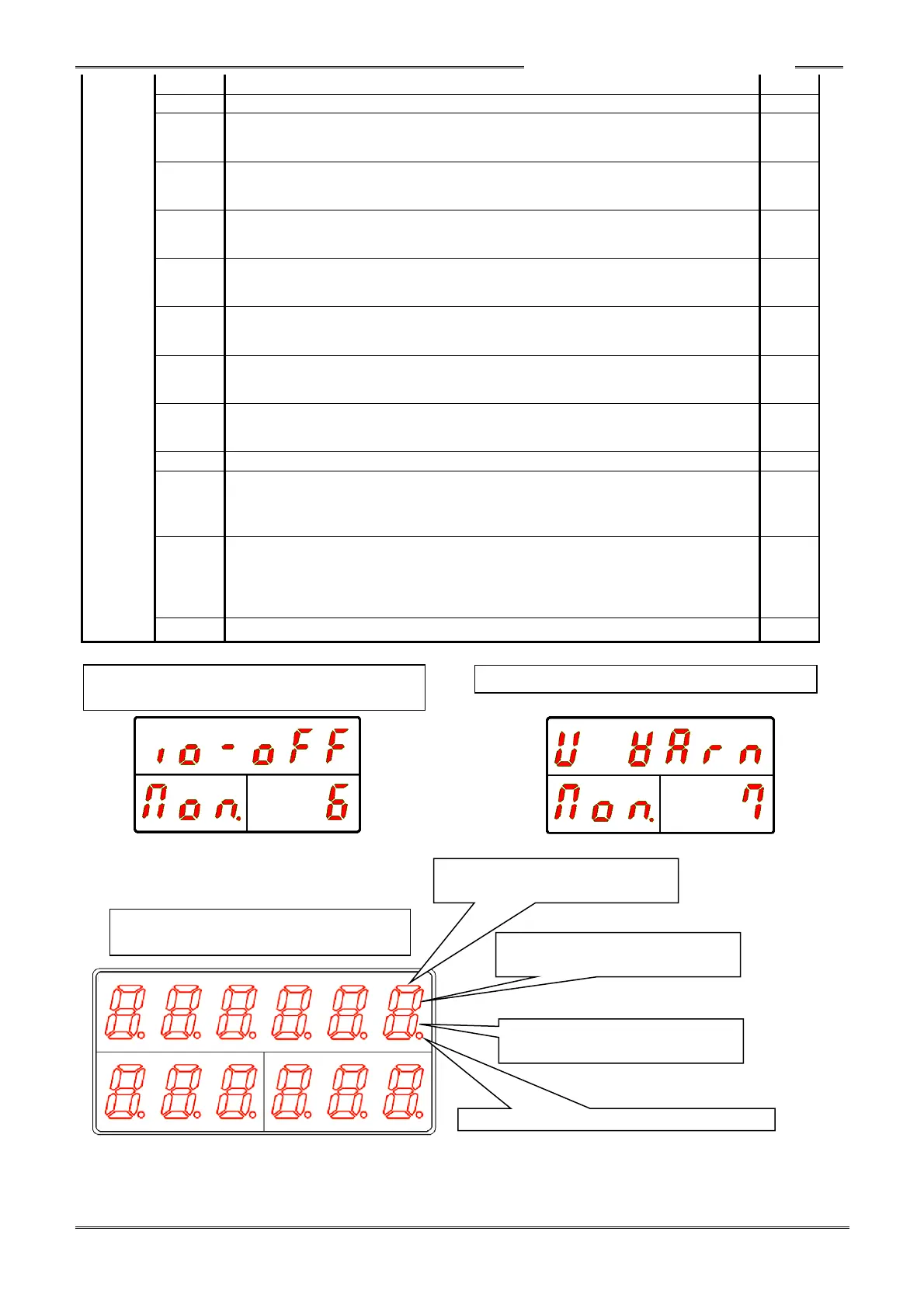

D-No. 006: External I/O Disabling Function

(DIP SW2: SW No. 6 is ON)

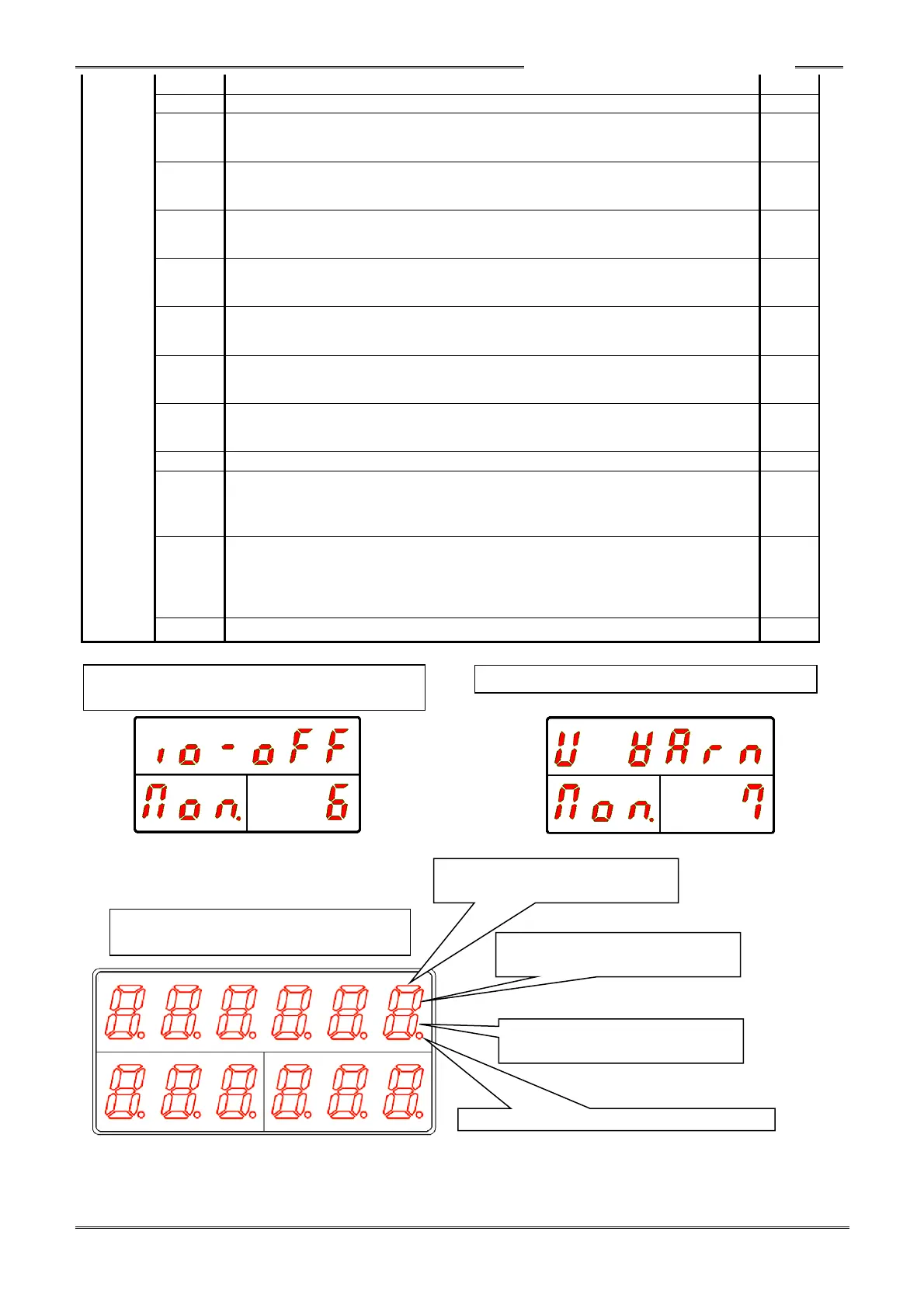

D-No. 7: ZERO/CAL Voltage Error Warning

D-No. 006: Simplified I/O Monitor

(DIP SW2: SW No. 6 is OFF)

Lit up during forced output (all digits).

Standard Inputs (lit up if ON)

bit0 ... bit11

Standard Outputs (lit up if ON)

bit0 ... bit11

AUX. Input (lit up if ON)

Batch reset input signal

Loading...

Loading...