Chapter 6 Fastening Operation

PAGE 6-11

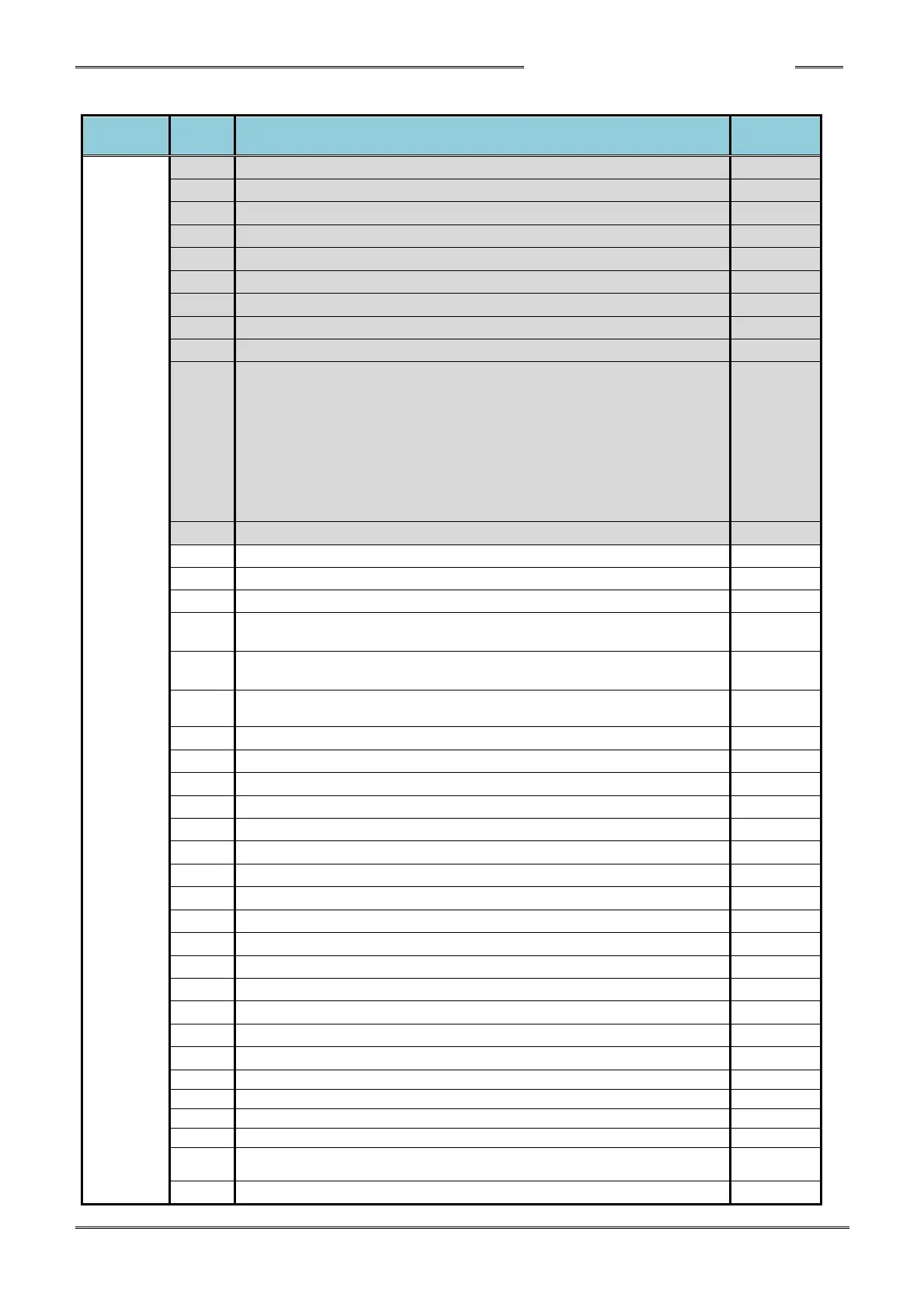

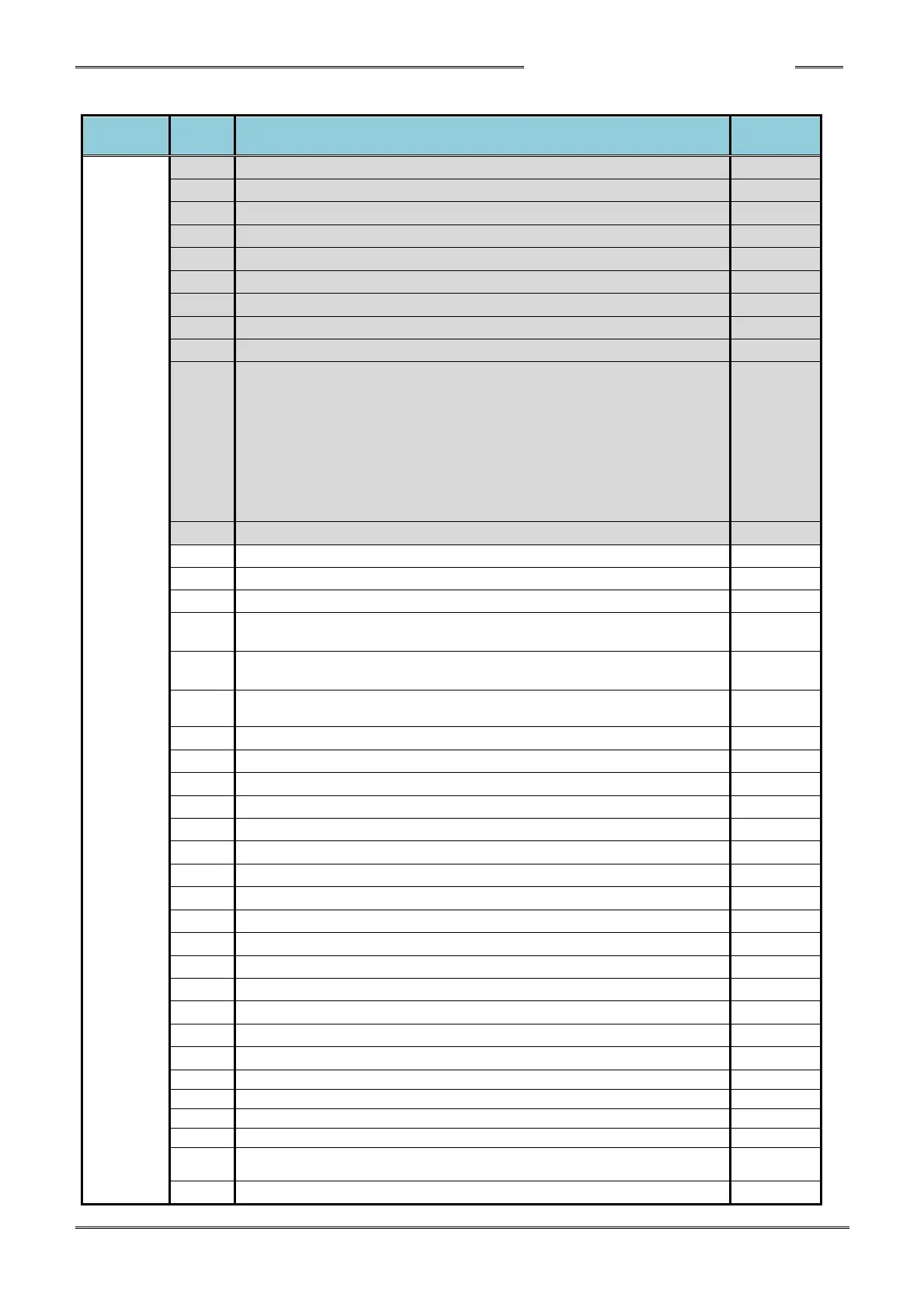

●List of Contents Indicated in the Fastening Result Mode (Reject display rotates (auto) for gray items only)

Fastening Result

reject:REJECT(Fastening NG)

accept:ACCEPT(Fastening OK)

abn:Stop by ABNORMAL(Abnormal occurs) signal

stop:Stop by loss of the STOP (Emergency Stop) Signal

reset:System clear by RESET(Reset) Signal

bypass:Stop by BYPASS(Bypass) Signal

st-off:START signal loss during BUSY (while operating) signal

1st Reject item (The D-No. of the fastening Reject item that occurred first is displayed)

Fastening method (trq: torque method, ang: angle method

Number of fastening steps

Self-Check Flag (SC)

ON :Check Performed OFF :Check Not Performed

Reverse Flag (RV)

ON :Reversed OFF :Not reversed

Servo lock flag (SL)

ON: servo lock performed OFF: servo lock not performed

SNUG Torque Judgment tq H

Final Torque (Offset Torque) tq H/L

Rate 1 Incremental Torque

Rate 2 Incremental Torque

Rate 3 Incremental Torque

Peak Current during fastening H/L (Current High/Low Limit Warning Display)

Current (Amp) Value at the time when fastening is completed

Axis cycle count (×1 million) * “--" if less than 1 million cycles

Tool cycle count (×1 million) * “--" if less than 1 million cycles

ACCEPT COUNT *0 to cycle count (0 to 99)

This DATA is always [c##] for COUNT/D-No. 00.

Peak Torque (Upper Display) Final Angle (Lower Display)

Loading...

Loading...