Chapter 6 Fastening Operation

PAGE 6-20

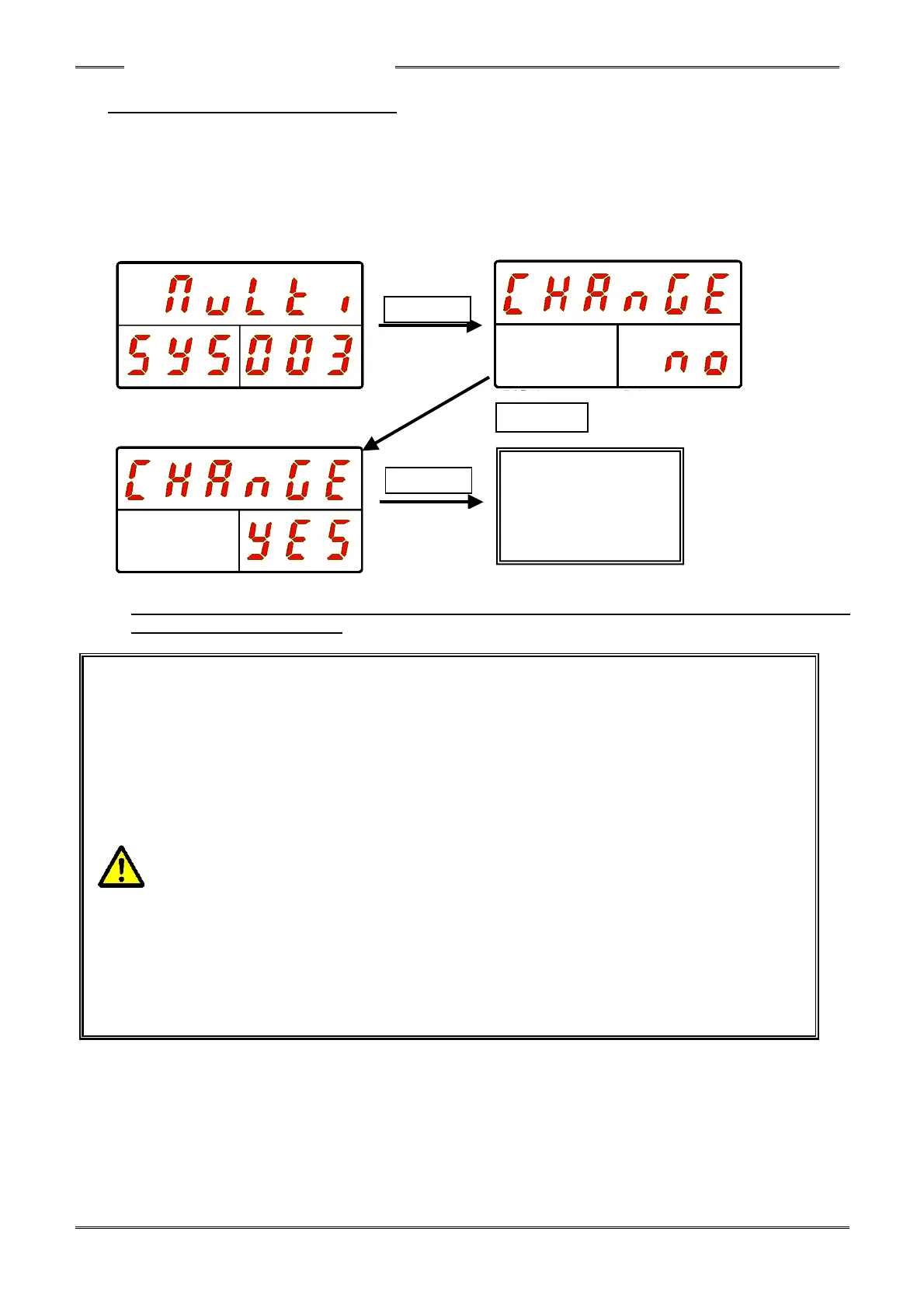

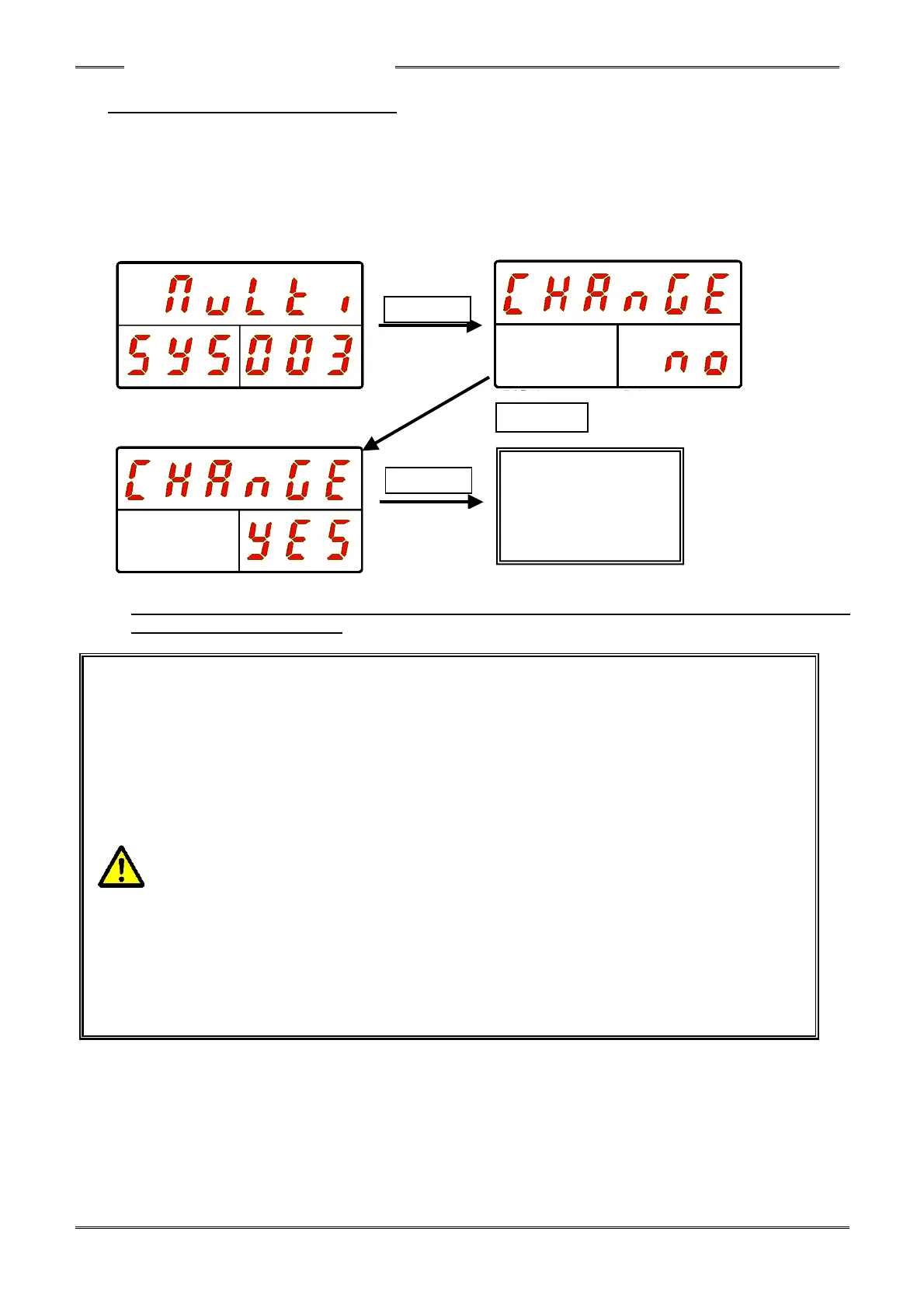

● System Parameter Setting Method

Parameter displayed with [SYS] in the PAR No. display is a System Parameter.

Press the [SET] push-button after editing the parameter. Once the SET push-button has been

pressed the [DATA] display will show “CHAnGE”and “no” will appear on the “D-NO” display.

“yES” or “no” can be selected by pressing the [▲] and [▼] buttons. If “yES” is selected, confirm the

entered data by pressing the [SET] button. The [SET] and [MODE] buttons will have no effect when

“no” appears.

*If neither YES or NO is not selected within 2 seconds, the new data will be ignored and the system

will exit the “Data Edit Mode”.

・The changed value will be saved into the internal memory at the moment the

BYPASS / PROGRAM mode is changed from BYPASS to RUN or when the BYPASS

signal turns from ON to OFF.

・If the power is turned off when changing the set value in BYPASS mode, the changed

value will be canceled and will be set back to the original value.

・Some of the system parameters (PAR No.000) are not changed, until the control

power is rebooted. (D-No.003 Function Version, D-No.011~016 TCP/IP Setting etc.)

・When the Controller Tool No. (PAR No. “SYS,” D-No. “200”) is changed, the fastening

parameter set values are subject to initialization and automatic correction due to the

tool size being changed.

・ The calibration torque, Rate 1 - 3 high and low limits, Full Scale current, High current

limit, and the Current limit are subject to re-initialization (Power off/on).

・ If the Torque, Speed, or Current low limit set value falls outside the high or low limit

value of the tool for which the set value was changed, this set value is subject to

automatic correction.

Loading...

Loading...