Installation Instructions

9.12.10 Panda_5000i_PMS_eng.R01 - Kapitel/Chapter 5: Installation Instructions Seite/Page 59

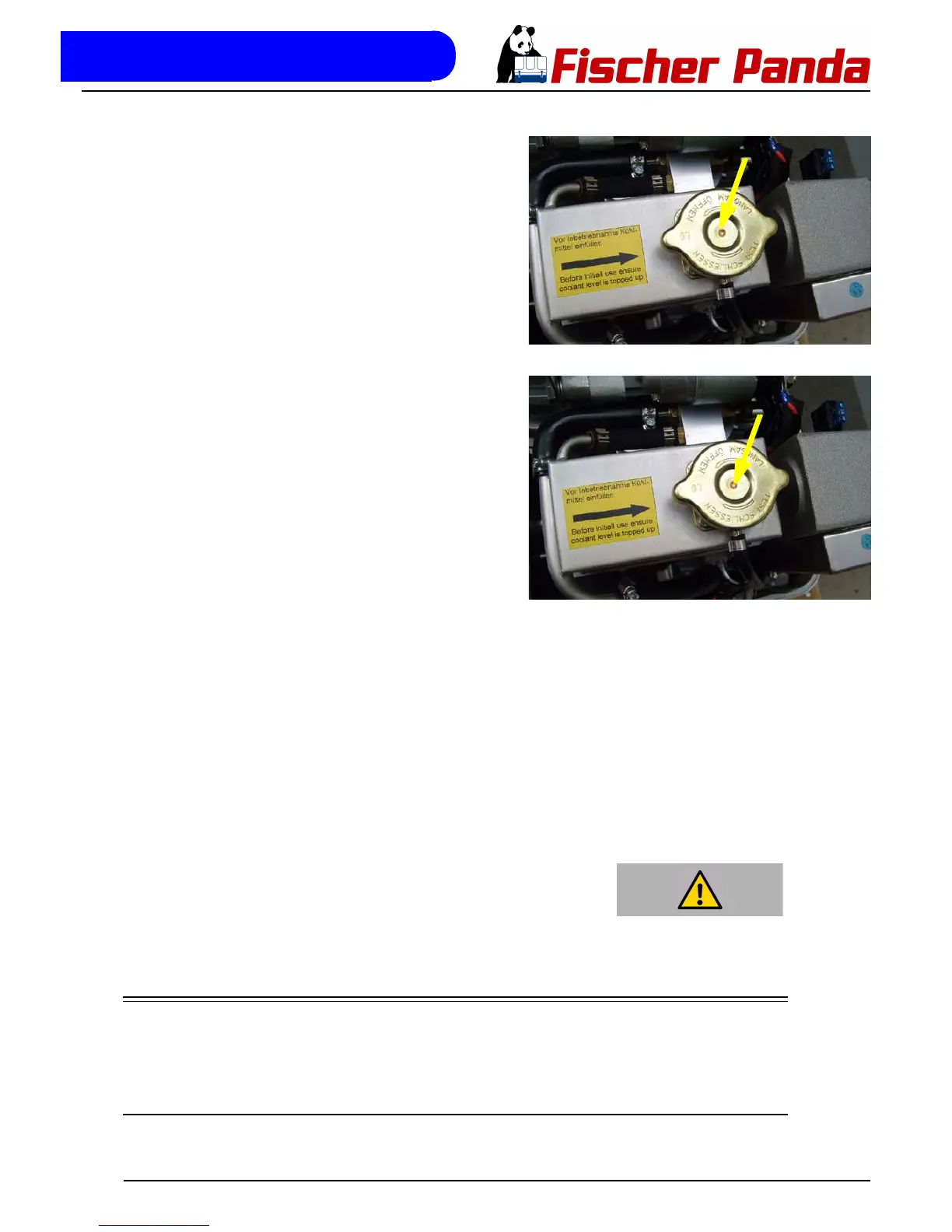

Fig. 5.5.1-1: Cooling water filler neck

2. Filling the cooling water circle

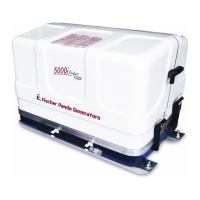

Fig. 5.5.1-2: Cooling water filler neck

a. Fill in the prepared mixture (cooling water with anti-

freeze protection according to the intended mixture) at

the filler neck at the cooling water tank slowly so long,

until cooling water reach the max. level at the neck.

Anti-freeze

In the interest of safety, the freezing point of the closed circuit coolant should be checked on a regular basis. Be

sure that the coolant/antifreeze mixture is good for at least -15°C (5°F) and if it is possible that y our genset experi-

ences lower temperatures, for example during storage or transportation, then the entire cooling system should be

drained and purged. To purge the cooling system, compressed air at about 0.5 bar (7.5 psi) is sufficient.

Electric cooling water pump

Connect the cooling water pump to an external DC power supply and start the pump. Refill the the cooling water at

the filler neck while the pump runs.

3. De-aerating

The cooling water circuit of the generator is self de-aerating.

ATTENTION! During the de-aerating process it must be checked again

and again if the cooling water is indeed circulating. If air

bubbles established in the internal cooling water pump,

it could be, that the cooling water circuit is not circulate.

Then the generator would be warming very fast and swit-

ched off by overheating.

5.6 Watercooled Exhaust System

By injecting the outlet raw water into the exhaust manifold, the exhaust gases are cooled and the noise emissions

from the exhaust system are reduced.

5.6.1 Installation of the standard exhaust system

The generator exhaust system must remain completely independent and separate from the exhaust system of any

other unit(s) on board. The exhaust hose has an inner diameter of 40 mm (1.6") (Panda 15000 and above approx.

Loading...

Loading...