Installation Instructions

Seite/Page 72 Panda_5000i_PMS_eng.R01 - Kapitel/Chapter 5: Installation Instructions 9.12.10

tions "Bleeding Air from the Fuel System" must be read after initial operation or after it has stood still for a long

period, in order to preserve the starter battery.

ATTENTION!

Non-return valve for the fuel return pipe

If the fuel tank should be installed over the level of the genera-

tor (e.g. daily tank), then a non-return valve must be installed

into the fuel return pipe to guarantee that through the return

pipe no fuel is led into the injection pump.

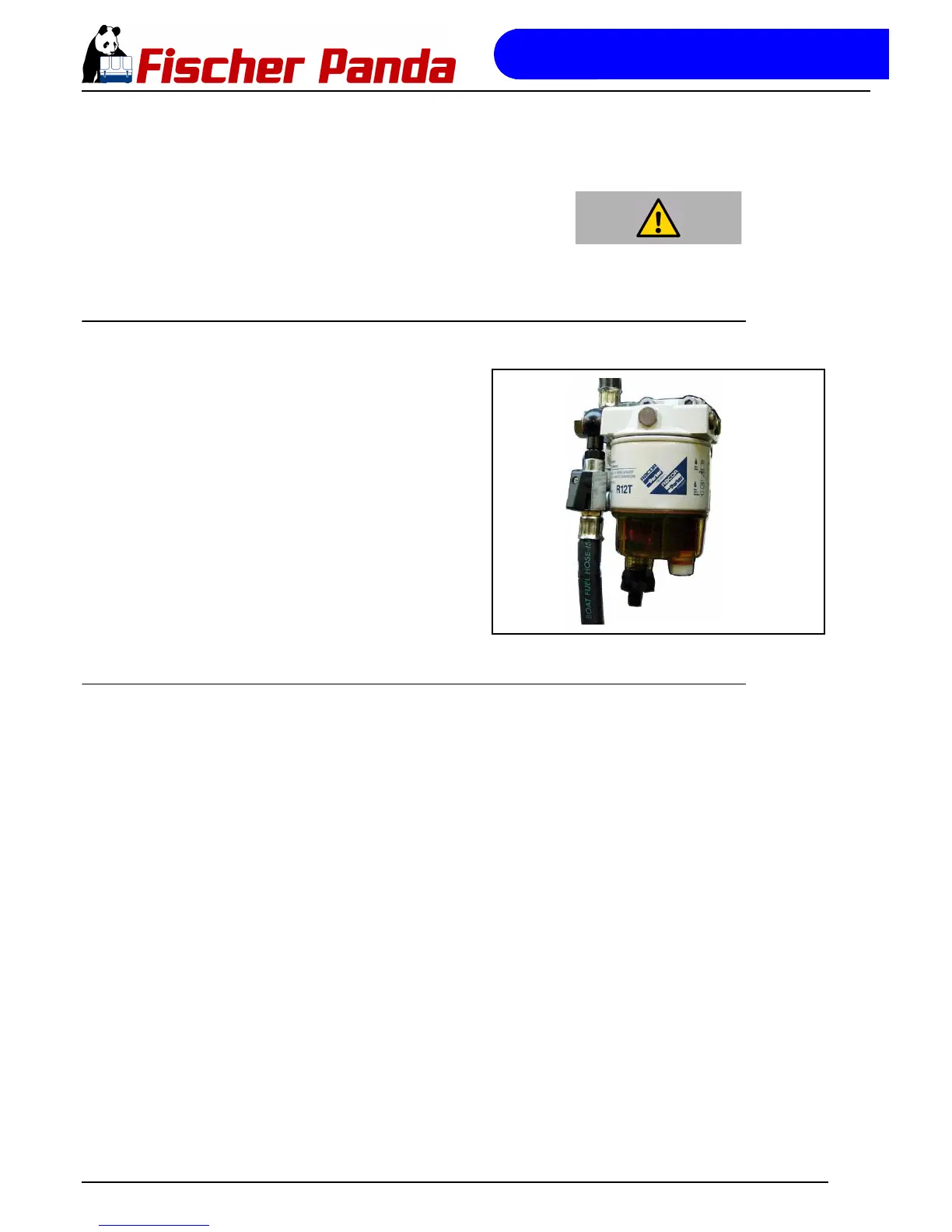

5.7.4 Position of the pre-filter with water separator

Fig. 5.7.4-1: Pre-filter with water separator

Additionally to the standard fine filter a pre-filter with water

separator must be installed outside of the sound insulation

capsule in the fuel system line (not included in the delivery).

5.7.5 Ventilating air from the fuel system

Normally, the fuel system is designed to vent air itself i.e. as soon as the electric starter motor starts; the fuel pump

starts working and the fuel system will be air-vent automatically after some time. It is, nevertheless essential, to vent

the system as follows prior to the first operation (as all hoses are empty):

1. Switch main power switch on control panel "ON".

2. Push failure bypass switch and hold tight.

The electric fuel pump has to be run audibly. By moving the failure bypass switch you can hear the solenoid valve of

the generator starting and stopping (when the sound insulation cover is taken off).

3. After the fuel pump has been running 3 to 4 minutes, because the failure bypass switch has been pressed down,

the bleeding screw of the solenoid valve has to be unscrewed. The switch has to be continuously depressed, when

opening the screw. A piece of cloth or absorbent paper should be put under the connection to avoid fuel entering the

sound insulation cover.

4. The air vent screw can be screwed in again, as soon as fuel runs out without bubbles. Then release the depres-

sing the failure bypass switch.

5. Starting the generator

Now the generator can be started by pushing the "START"-button. The generator should start after a short while.

One of the pipe union nuts of an injection hose has to be unscrewed, should the unit not start; then try to restart the

generator. After the generator has started, the pipe union nut has to be tightened again.

Main power switch "OFF"

Loading...

Loading...