EM100-C User Manual

0084292

Page 68 of 81

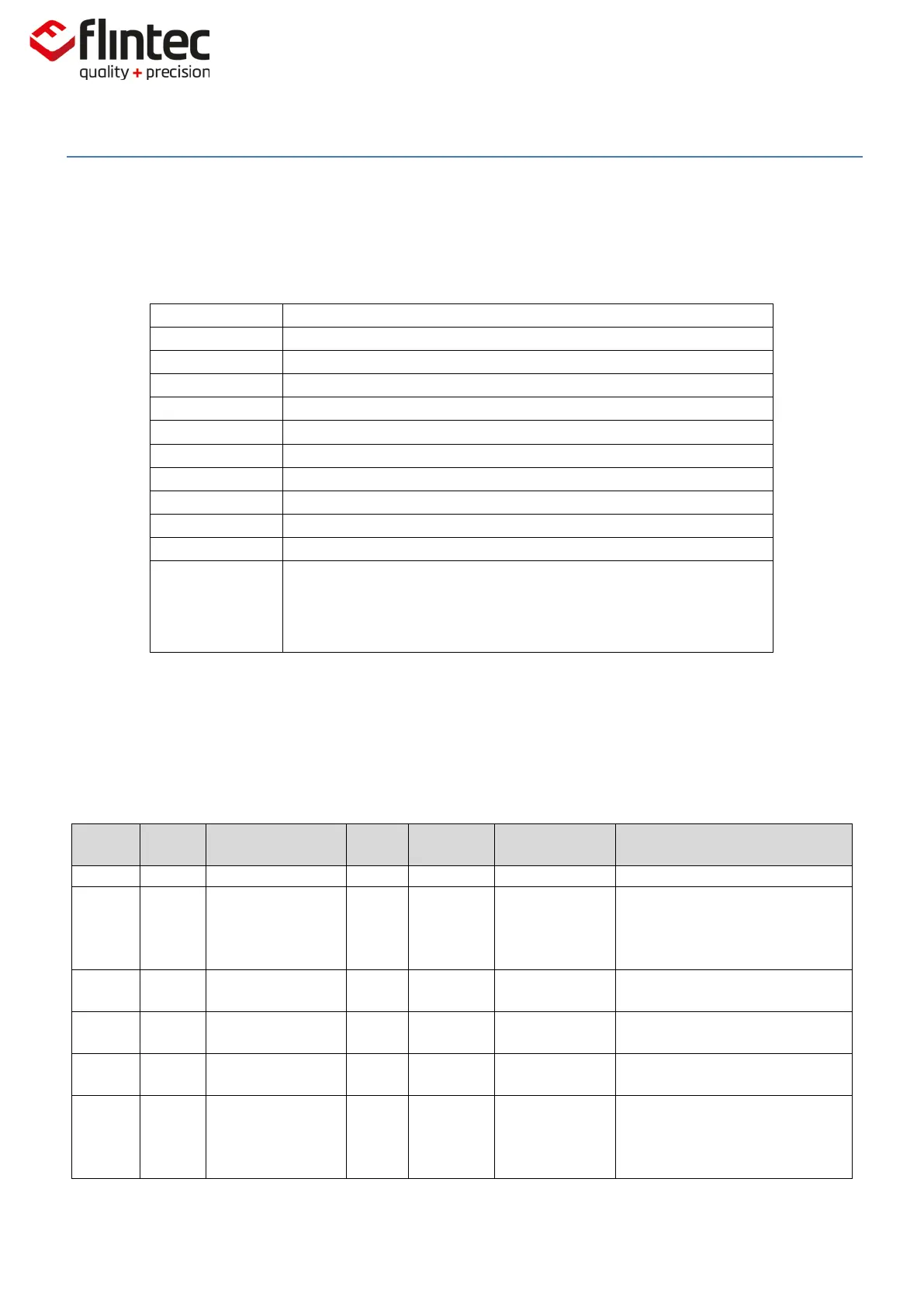

6.2. Communication Profile

Abbreviations used in tables:

32-bit IEEE754 Floating Point.

Traceable Access Code (incremented when saved).

Get the current TAC value by reading index 2300,3. Write the

same TAC value to this index to enable calibration. When the

calibration is saved, the TAC value auto increments by one.

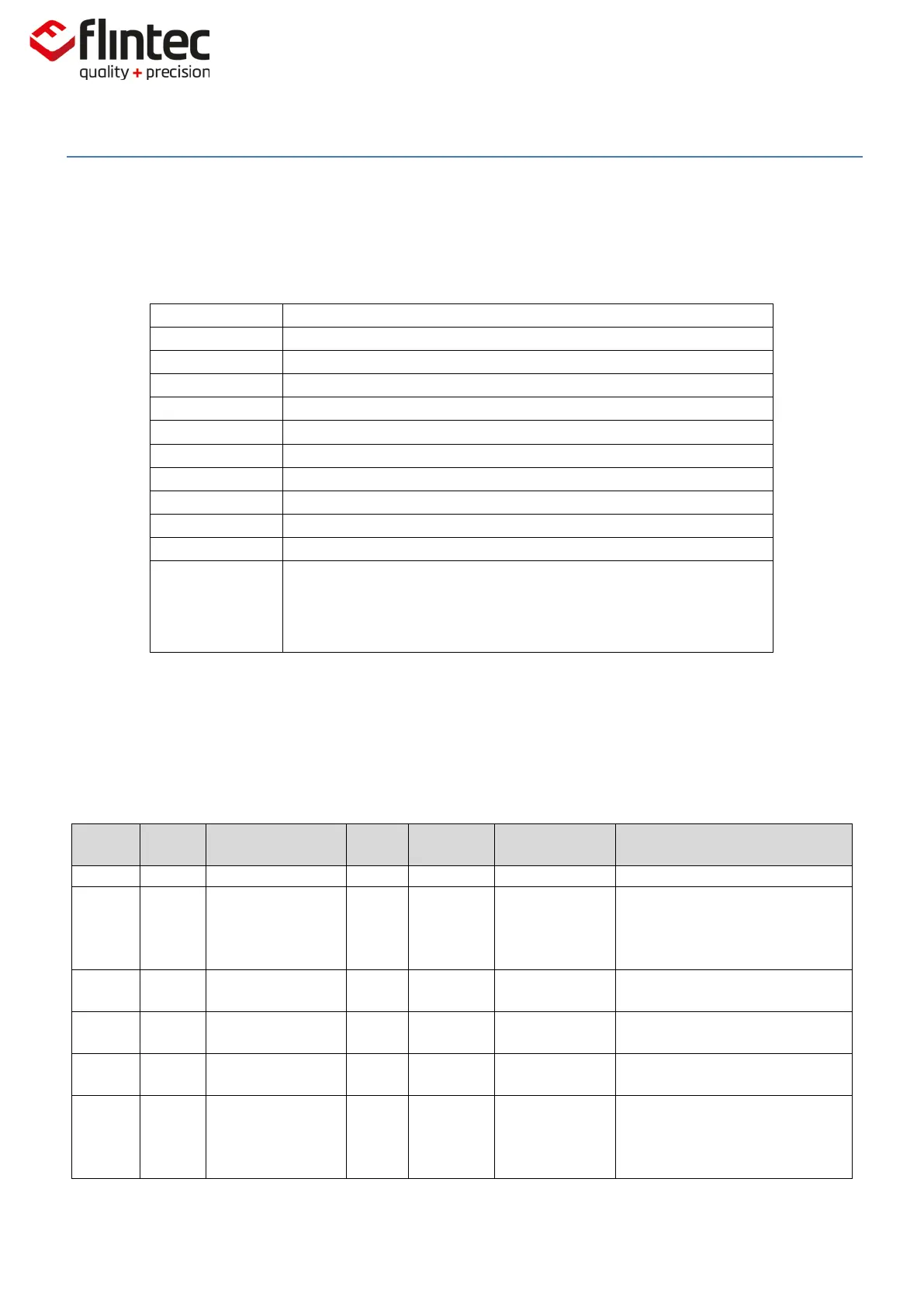

6.2.1. Object Dictionary

The EM100 object directory of the CANopen communication system is described below.

6.2.1.1. Communication Segment

Non-standard device profile.

Bit 1: Comms Error.

Bit 2: Manufacturer Specific

Error.

Status Register.

Message.

COB_ID of the Sync Message.

Period.

Cycle-Time in ms. Set by NMT

master. 100Chex. and

100Dhex. are used if index

Loading...

Loading...