- 146 -

15.Driving /clutch/driven wheel/foot driving device

Preparation documents-----15.1 Clutch/driven wheel----15.5

Failure diagnosis -15.2 Disassemble clutch and driven wheel --15.6

Left crankcase cover---15.3 Installation---------15.7

Driven disc------------------15.4 Foot starting device---15.8

15.1 Preparation documents

Note

in operation, no 注 oil shall stick to triangular belt, and shall be cleaned if any to minimize possibility of sliding between triangular

belt and wheel.

Function: driving disc/clutch/driven wheel form stepless speed variator. Driving disc 从 and driven wheel

transfer torsion through triangular belt.

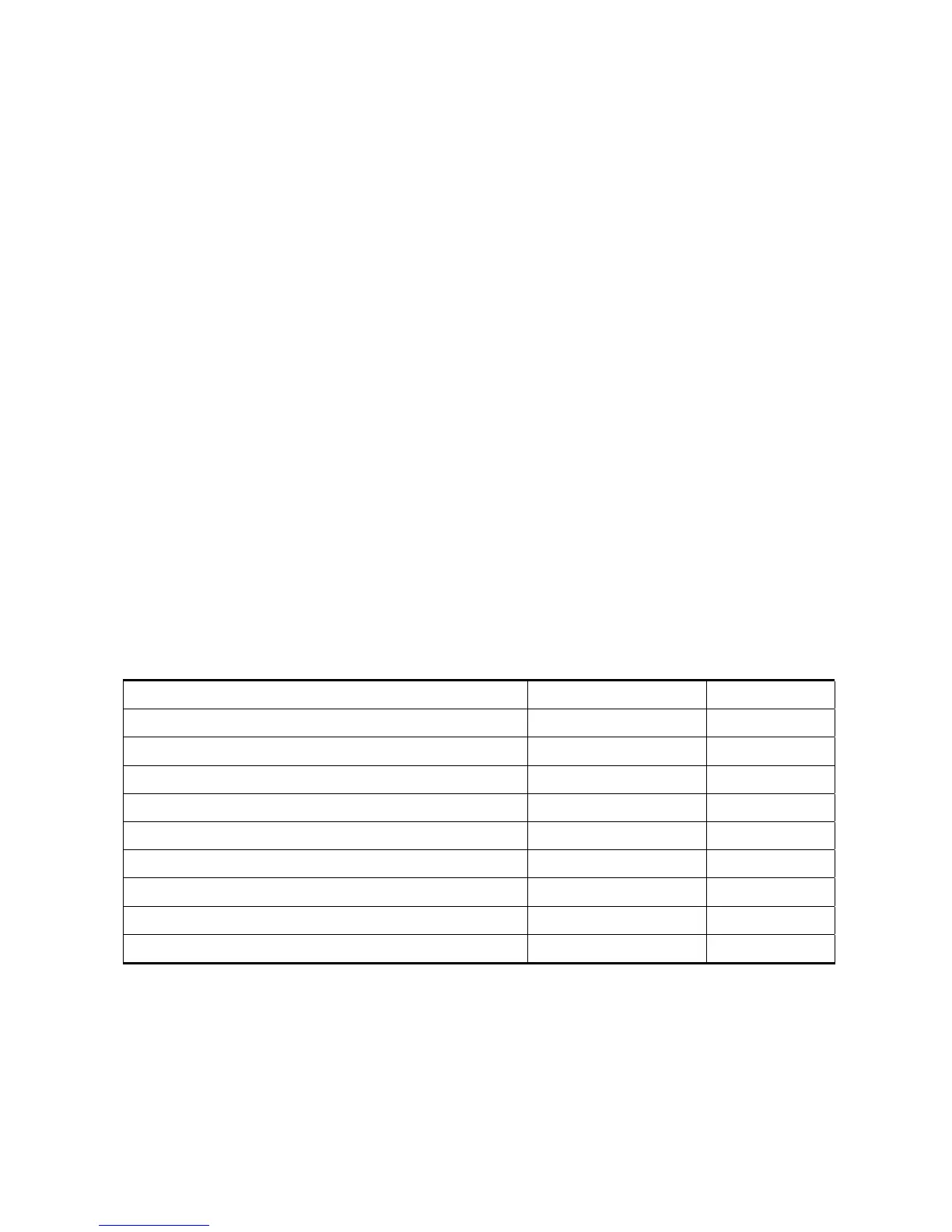

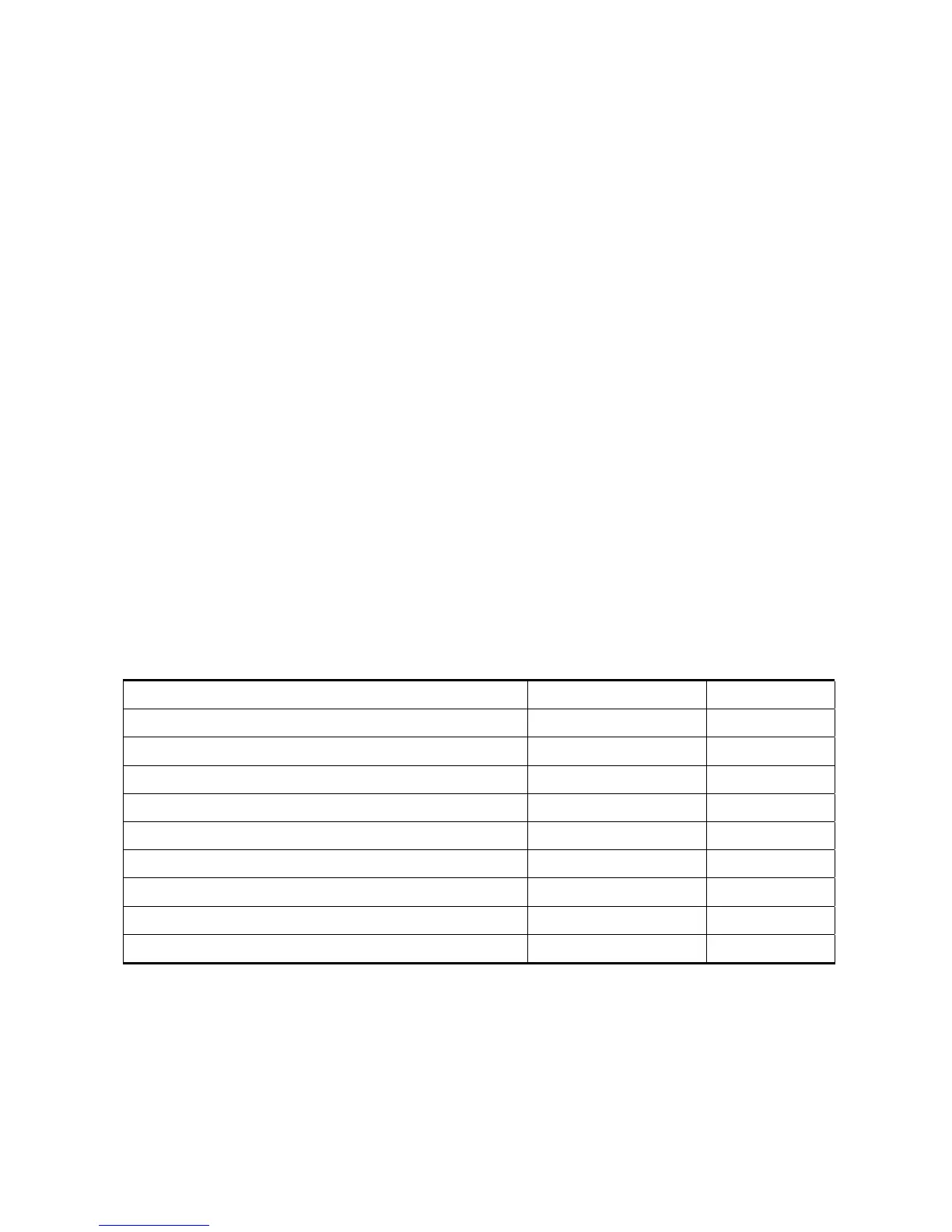

Preparation standard unit: mm

Item Standard value Usage limit

Right semi-diameter of driving wheel 25.989-26.052 26.06

OD of slid bushing 25.96-25.974 25.94

Width of triangular belt 17 16

Thickness of clutch abrasion piece 1.8 1.5

ID of clutch outer bushing 118-118.3 118.5

Free length of clutch compression spring 68-70 68

OD of driven wheel right semi-shaft 32.95-32.975 32.94

ID of driven wheel left semi slid bushing 33-33.025 33.06

OD of boll bearing 14.92-15.08 14.4

15.2 Failure diagnosis

Motor fails not make cycle run low horsepower shaking driving

Worn triangular belt Worn triangular belt broken clutch abrasion piece spring

Loading...

Loading...