3 System Description

User Guide 17

3.1.2 SYSTEM COMPONENTS

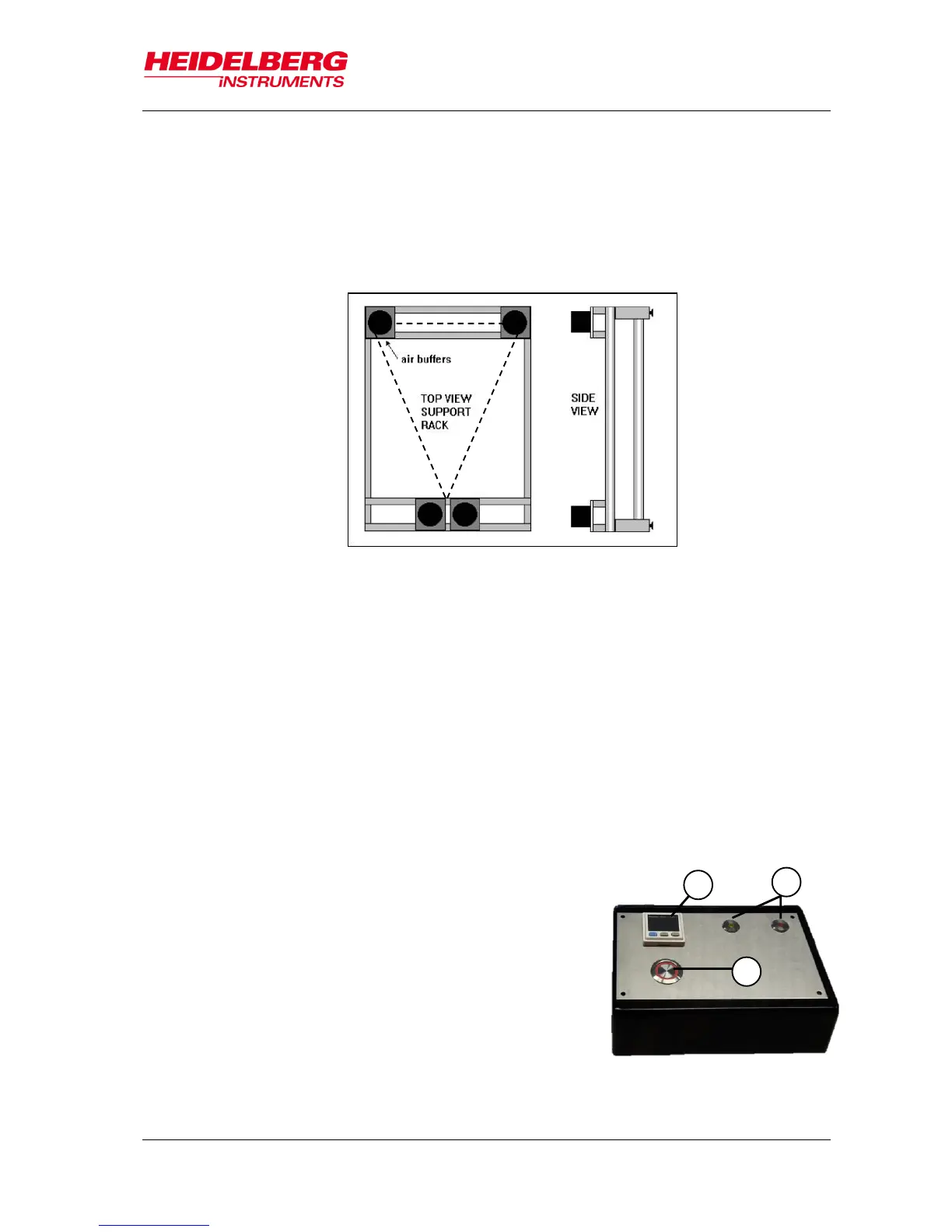

SYSTEM SUPPORT

A heavy-duty aluminum construction and four buffers that are filled with air to ensure

vibration isolation support the granite base plate. To avoid any unnecessary bending

forces in the base plate, these buffers are arranged in a triangular geometry (the two

buffers at the front side are close together and act as one point).

HEIGHT-ADJUSTABLE FEET

The granite construction stands on four height-adjustable feet. By varying the height

of the feet the system is leveled in correspondence with the ground condition in the

location the system is installed. The castor wheels of the flow box are not height-

adjustable.

BASE PLATE (MAIN BLOCK)

The main unit has a granite base that gives stability to the system. It has been

selected for its low thermal expansion coefficient. The granite base plate is

supported by air buffers that ensure effective vibration isolation and has threaded

holes to accept other system components. Medium and high-power lasers are

mounted at the bottom of the base plate to minimize heat generation in the areas

that are sensitive to heat.

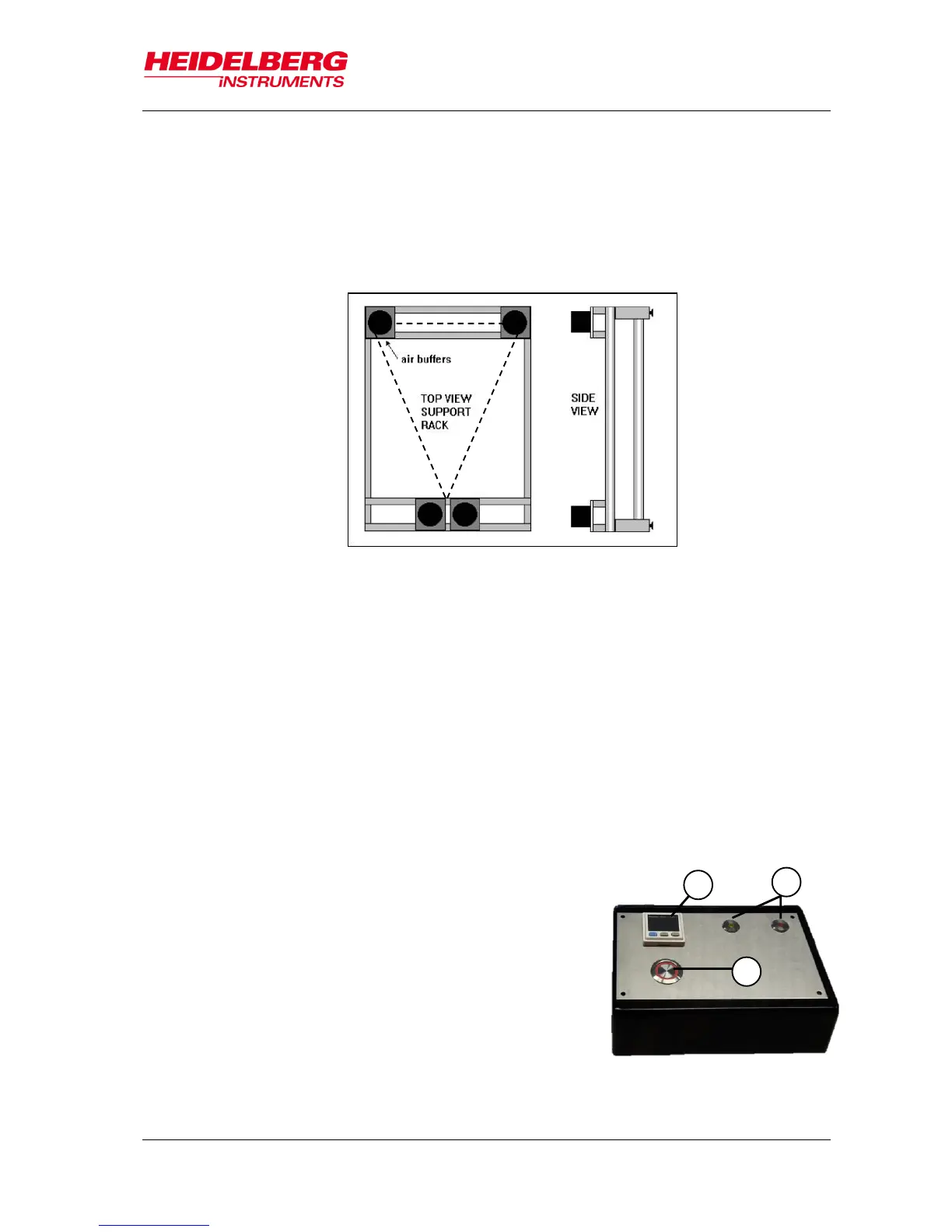

OPERATOR PANEL

The operator panel has a push button (1) that opens

the vacuum inlet to fix the substrate on the chuck. For

observing the vacuum status, a display (2) shows the

current vacuum status. However, it is not necessary to

observe the status because the wizard informs about

vacuum supply problems. The panel also contains two

LED lights (3) indicating the status of the laser. The

lights are on throughout the whole exposure

procedure. When the window is open, the lights are

off indicating that the laser(s) is (are) off (see 4.2.3

Info Section).

Loading...

Loading...