3. Operation

Fieldbus Communication

76

RCP6

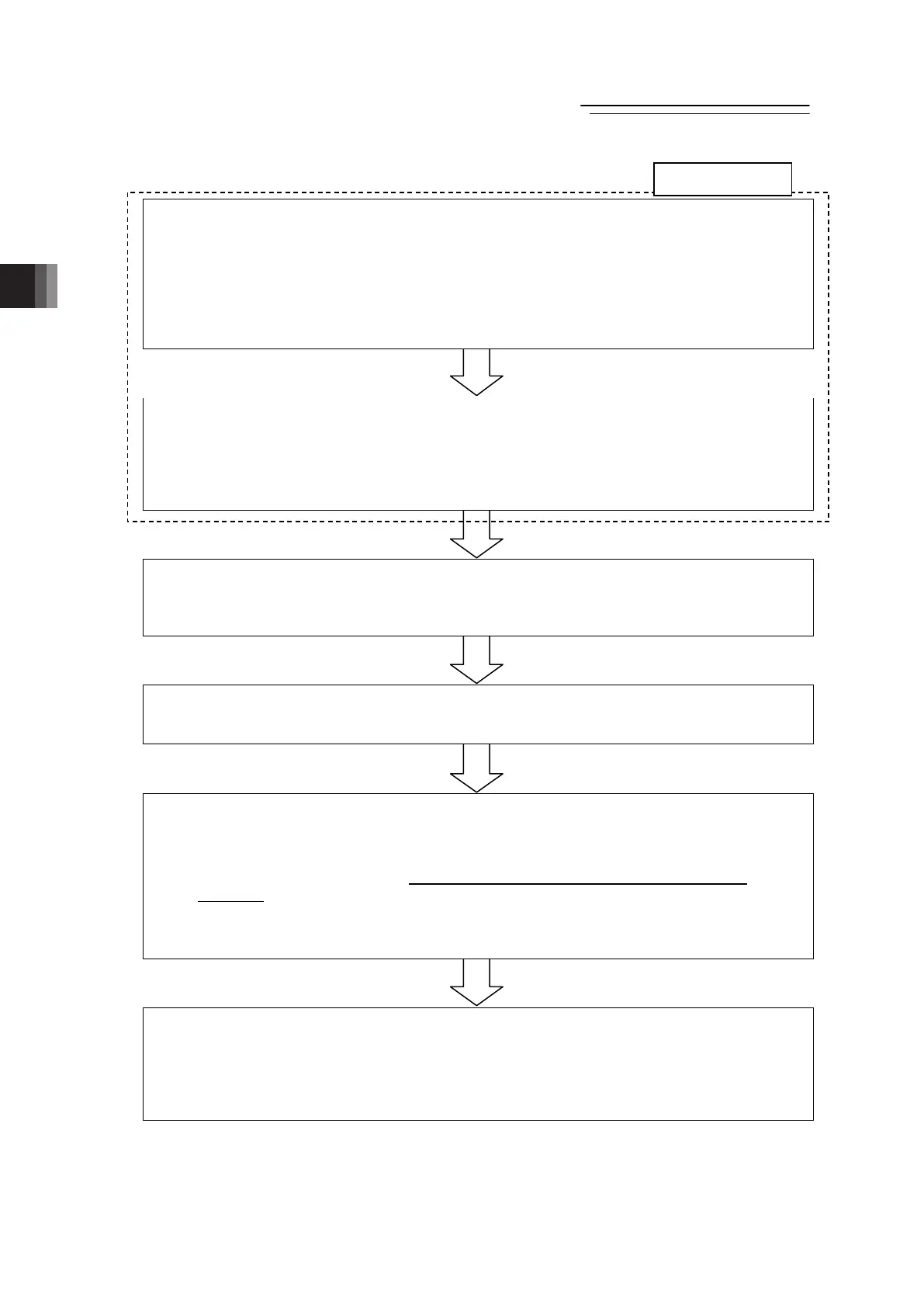

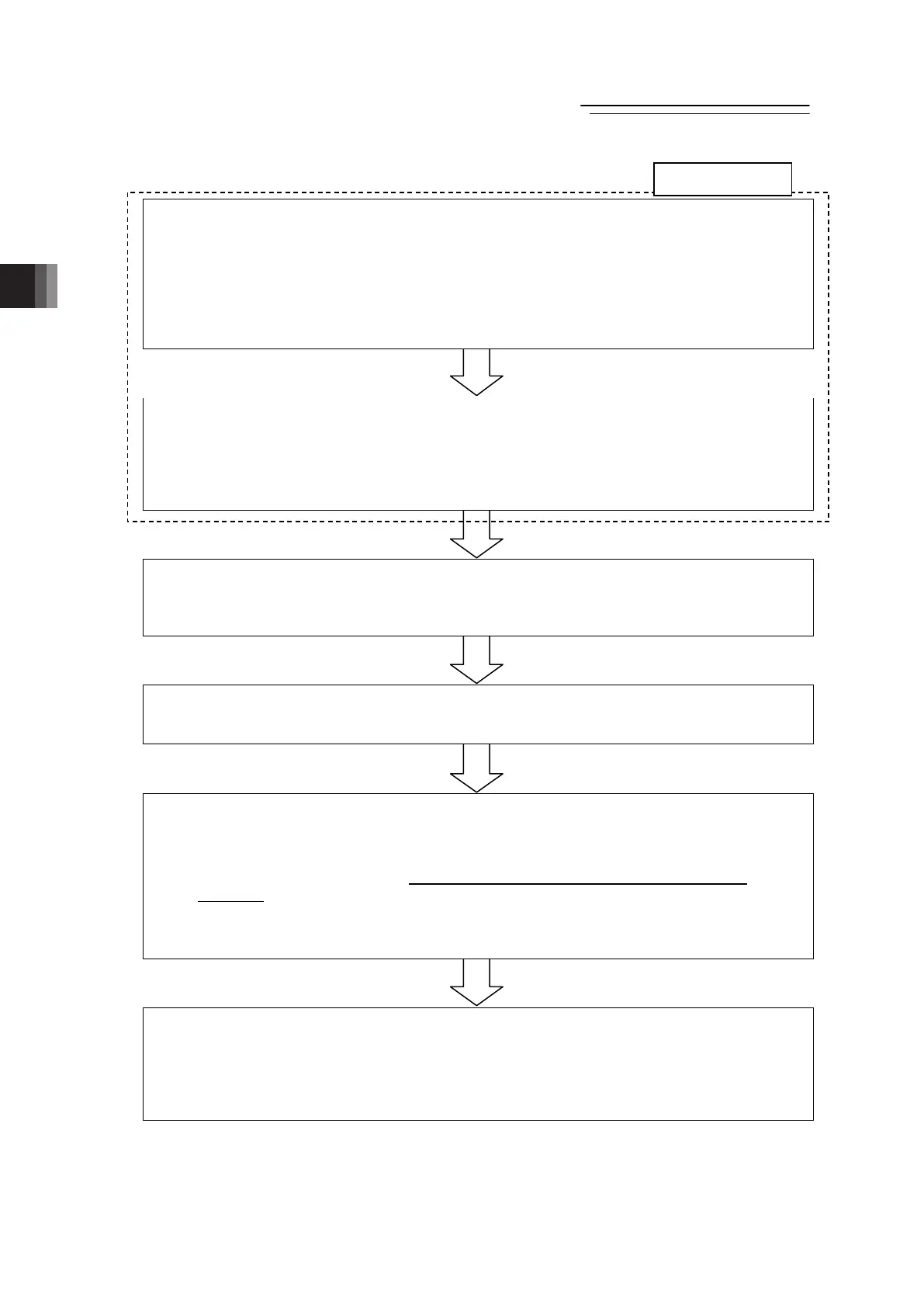

[Basic Operation Procedures]

[1] Operation Mode Setting [Refer to Sections 3.2.1 and 3.8]

Establish the settings for those such as the slave addresses in the Fieldbus using Gateway

Parameter Setting Tool. Establish the settings of the operation mode for all the axes.

1) Establish the setting following the procedure described in Section 3.2.1.

All the connected axes will be in the same operation mode.

2) Setting the gateway parameters to suit the system to be used.

Establish such conducting as the calendar function (clock setting) use or the speed unit

change in Direct Indication Mode.

[2] Parameter Settings [Refer to Sections 3.2.2]

Establish the parameter settings on all the connected axes by using a teaching tool such as

the PC software.

Set the zone (Parameters No.1 and 2) and soft limit (Parameter No.3 and 4) that suit to the

system.

[Refer to Chapter 8 Parameter]

[3] Setting of Position Data [Refer to Sections 3.3]

(Note) Setting of Direct Indication Mode is not necessary.

Set the data for those to be used such as target position, speed, etc. to the position

data.

[4] Fieldbus Settings [Refer to Sections 3.4.1 and 3.4.2]

Assign RCP6S gateway to PLC (master unit).

[Refer to the instruction manuals for the master unit and PLC]

[5] Link to Network

1) Put the operation mode setting switch on the front panel of RCP6S gateway unit to AUTO

side and reboot the power. (By putting to AUTO, Fieldbus line activates.)

2) Once the link to PLC (master unit) is established

(Note 1)

, turn ON MON Signal of the

gateway control signals

(Note 2)

. While MON Signal is ON, control from fieldbus is

available.

Note 1: By referring to 3.9 Fieldbus status LEDs display, confirm that the communication is

established in the normal condition.

Note 2: Refer to 3.4.2 Control Signals of Gateway.

[6] Operation Control in Each Operation Mode [Refer to Sections 3.4.3 to 3.4.8]

1) Send the information of the target position, speed, acceleration/deceleration, etc. from

PLC (master unit) to the RCP6S gateway.

2) The actuator follows the received information of the target position, speed,

acceleration/deceleration, etc. to perform a positioning at the specific coordinates.

3) Confirm the status of positioning complete.

Initial Settin

3.1.1

Loading...

Loading...