ADJUSTMENTS AND SETUP

5

- 27 -

302.028

5.2.2 Bar pusher working position -

Adjustment

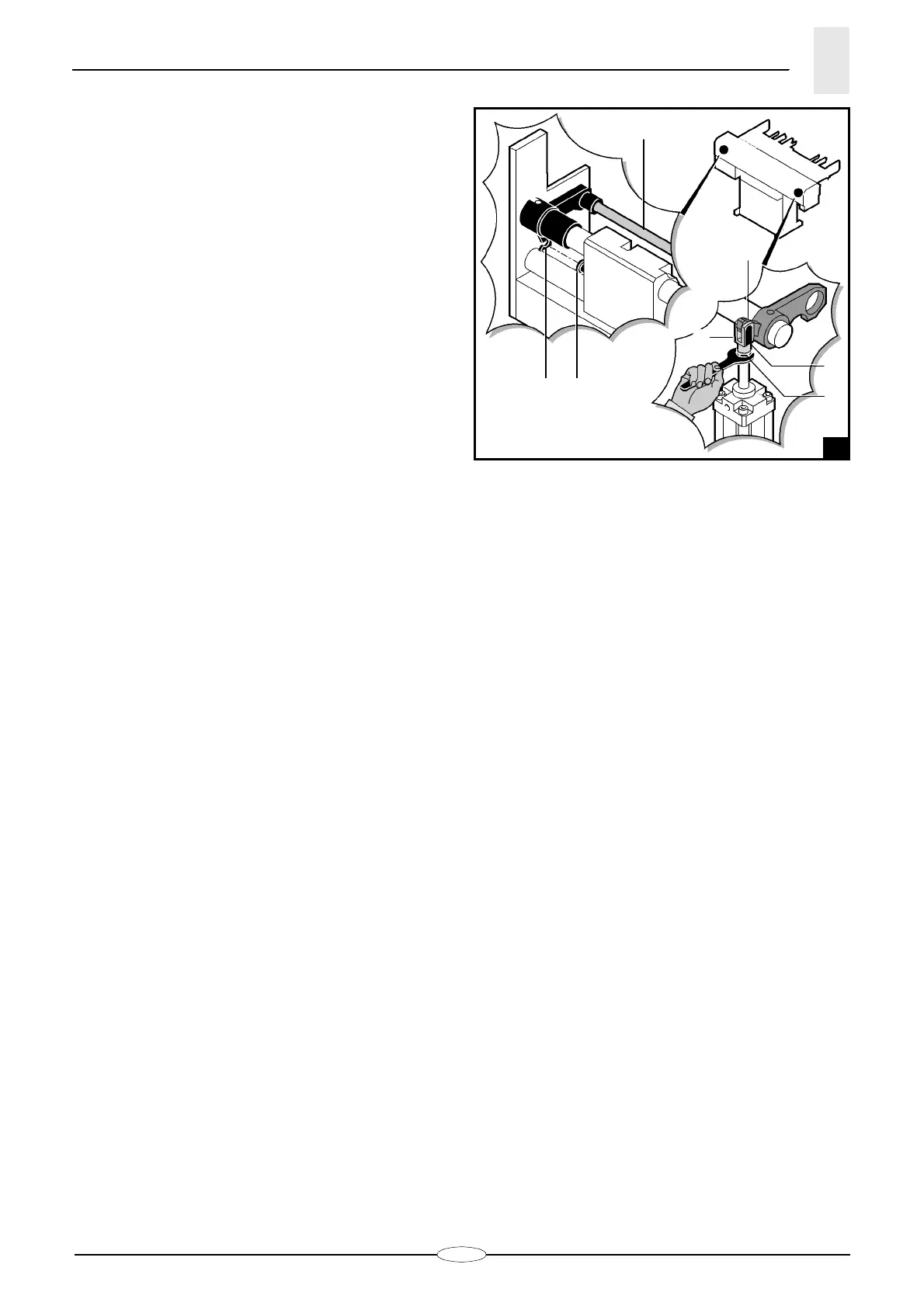

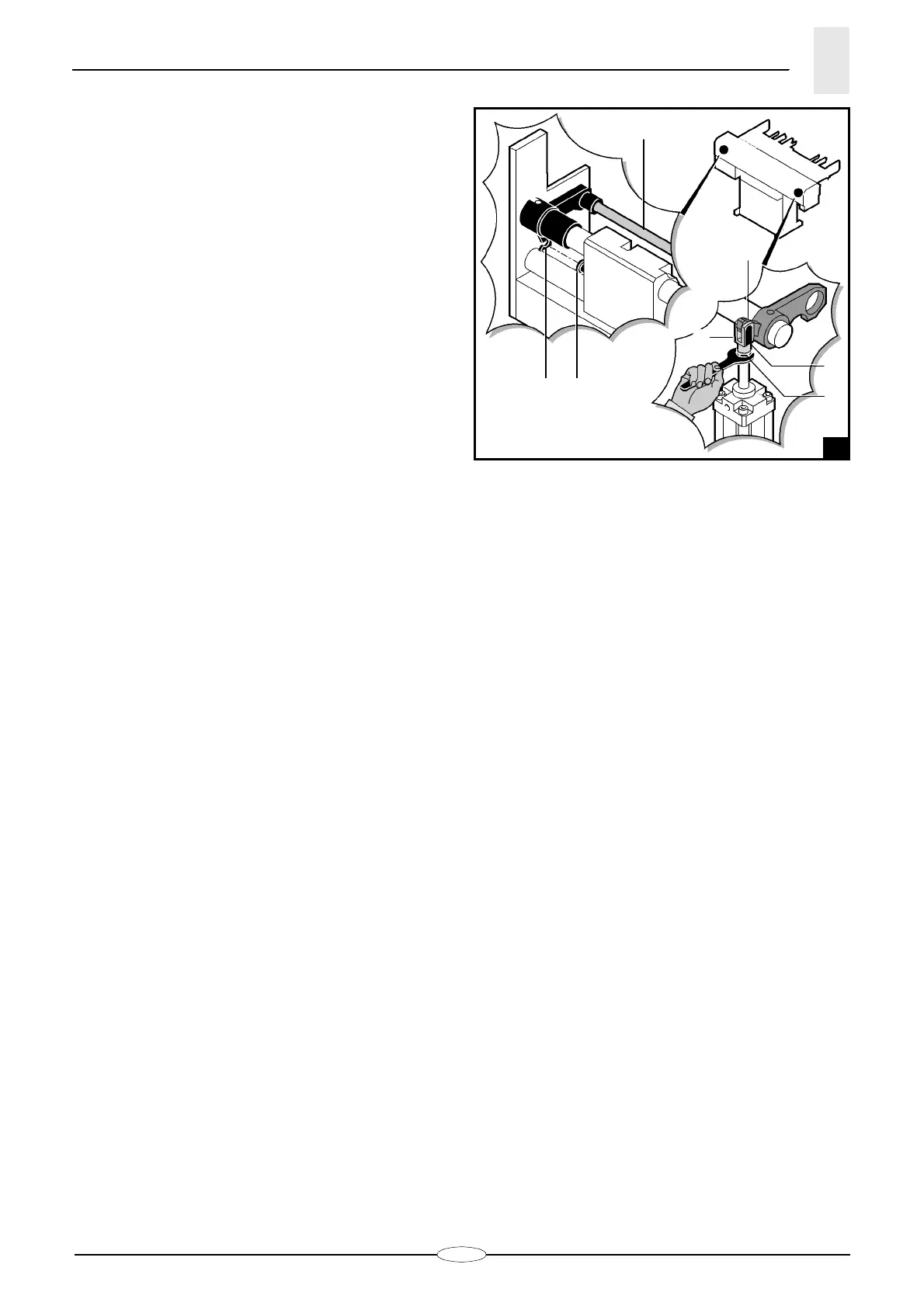

(fig. 2)

When the bar pusher

A

has been lowered, the groove

on lever

B

must be aligned with the carriage pin

C

.

To adjust the bar pusher working position:

– remove the rear guard;

– remove the pin

D

and pull the lever

E

;

– loosen the nut

F

. Then, either tighten or loosen the

fork pin

G

depending on what you need to do;

– tighten the nut

F

and fit the pin

D

again.

5.3. ADJUSTMENTS ACCORDING TO BAR TYPE

- FOREWORD

They include all the preliminary adjustments that must

be made according to the diameter, length and section

type of the bar to be machined.

5.3.1 Reduction sleeves - Diameter change-over.

5.3.2 Magazine inclination - Adjustment.

5.3.3 Bar selection - Adjustment.

5.3.4 Covering frame - Adjustment.

5.3.5 Guide lifting limit switch - Adjustment.

5.3.6 Bar pusher - Selection and installation.

5.3.7 Bar passage guide (optional) - Adjustment.

5.3.1 Reduction sleeves - Diameter change-over

To support bars in the lathe, it is advisable to insert

reduction sleeves into the spindle.

Their inner diameter shall be equal to the bar pusher

diameter + 1 mm.

Example:

to make sure that ø12 mm bar pusher never touches

the spindle inner part, the inner diameter of the spindle

liners must be at least 13 mm.

Loading...

Loading...