4.2 Pre-dive checks

The following should be performed prior to each dive:

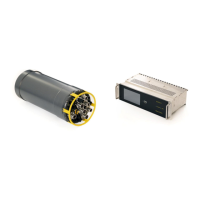

1. Check that the subsea canister is properly mounted and connected to cathodic protection

2. Ensure that the air vent fitting is firmly capped

3. Ensure that the end cap is properly mounted

4. Check and hand-tighten all connectors

4.3 Post-dive checks

The following should be performed after each dive:

1. Rinse the outside of the subsea canister with fresh water

2. Visually check for damage, scratches and pitting corrosion

3. Check all cables for wear or damage and hand-tighten all connectors

4.4 Cables and connectors assembly and disassembly

It is important for the reliability of the system that cables and connectors are assembled and

disassembled in a proper way.

Before assembly of cables please note the following points:

1. Ensure that the cable integrity are intact and that no pins are damaged or corroded.

2. Clean surface and pins with a suitable electro cleaner, type CRC 2.26 or equal.

3. Dry off with clean cloth or compressed air.

4. Grease the rubber section of the connector with a thin layer of Molycote 111 or equal.

5. Assemble the connector and tighten by hand.

6. All connectors that are not used must be plugged with depth rated dummy

connectors.

Important: Never use any kind of tool to tighten any of the connectors.

After the first dive it is important to check and tighten all connectors as they may appear to be

loose due to the influence of the water pressure during the dive.

When disconnecting any connector, check for damage and corrosion. If the connector will be

disconnected for a longer period, it is important to cover the unprotected parts using a suitable

dummy or protection cap.

Loading...

Loading...