142

7.4 SVPWM control

Goodrive200 series inverters provide internal SVPWM control which can be used in cases where it

does not need high control accuracy. It is also recommended to use SVPWM control when one

inverter drives multiple motors.

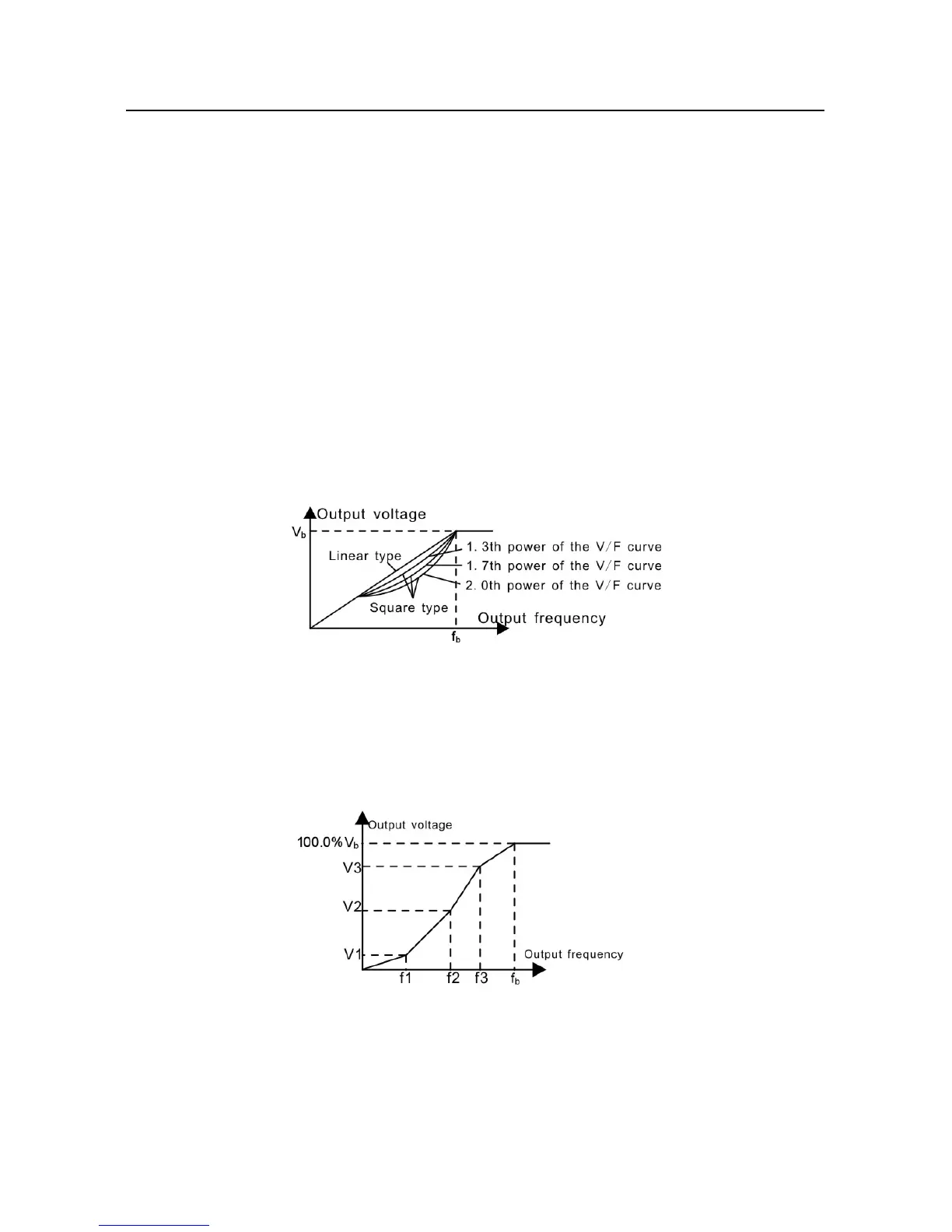

Goodrive200 series inverters provide multiple V/F curve modes. The user can select the

corresponding V/F curve to the site needs. Or they can set the corresponding V/F curve to their

own needs.

Recommendations:

For the load of constant torque, such as the conveyor belt which runs linearly. It is properly to

select linear V/F curve because it needs constant torque.

For the load of decreasing torque, such as fans and water pumps, it is properly to select

corresponding 1.3th, 1.7th or 2nd power of V/F curve because the actual torque is 2-squared or

3-squared of the rotating speed.

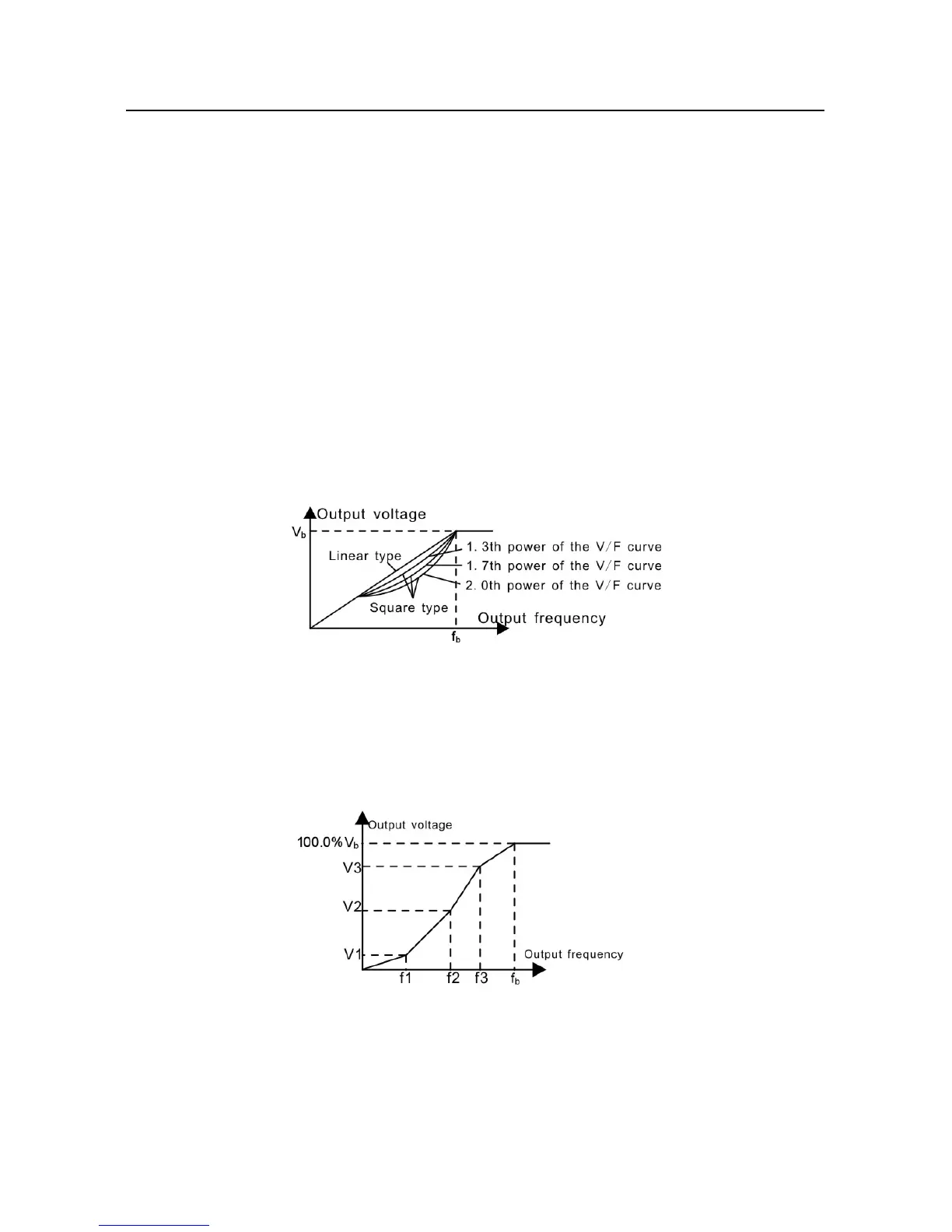

Goodrive200 series inverters provide multi-dots V/F curve, the user can change the output V/F

curve by setting the voltage and frequency of three middle dots. The whole curve is consisted of 5

dots. The starting dot is (0Hz, 0V), and the ending dot is (the basic frequency of the motor, the

rated voltage of the motor). During the setting processing: 0≤f

1

≤f

2

≤f

3

≤the basic frequency of the

motor; 0≤V

1

≤V

2

≤V

3

≤the rated voltage of the motor.

Goodrive200 series inverters provide special function code for SVPWM control mode which can

improve the performance of SVPWM control by means of setting.

1. Torque boost

Torque boost function can compensate the performance of low speed torque during SVPWM

Loading...

Loading...