73 / 123Issued: 13.08.2012 Version: KST PLC mxAutomation Logix 1.0 V1 en (PDF)

7 Programming

Outputs

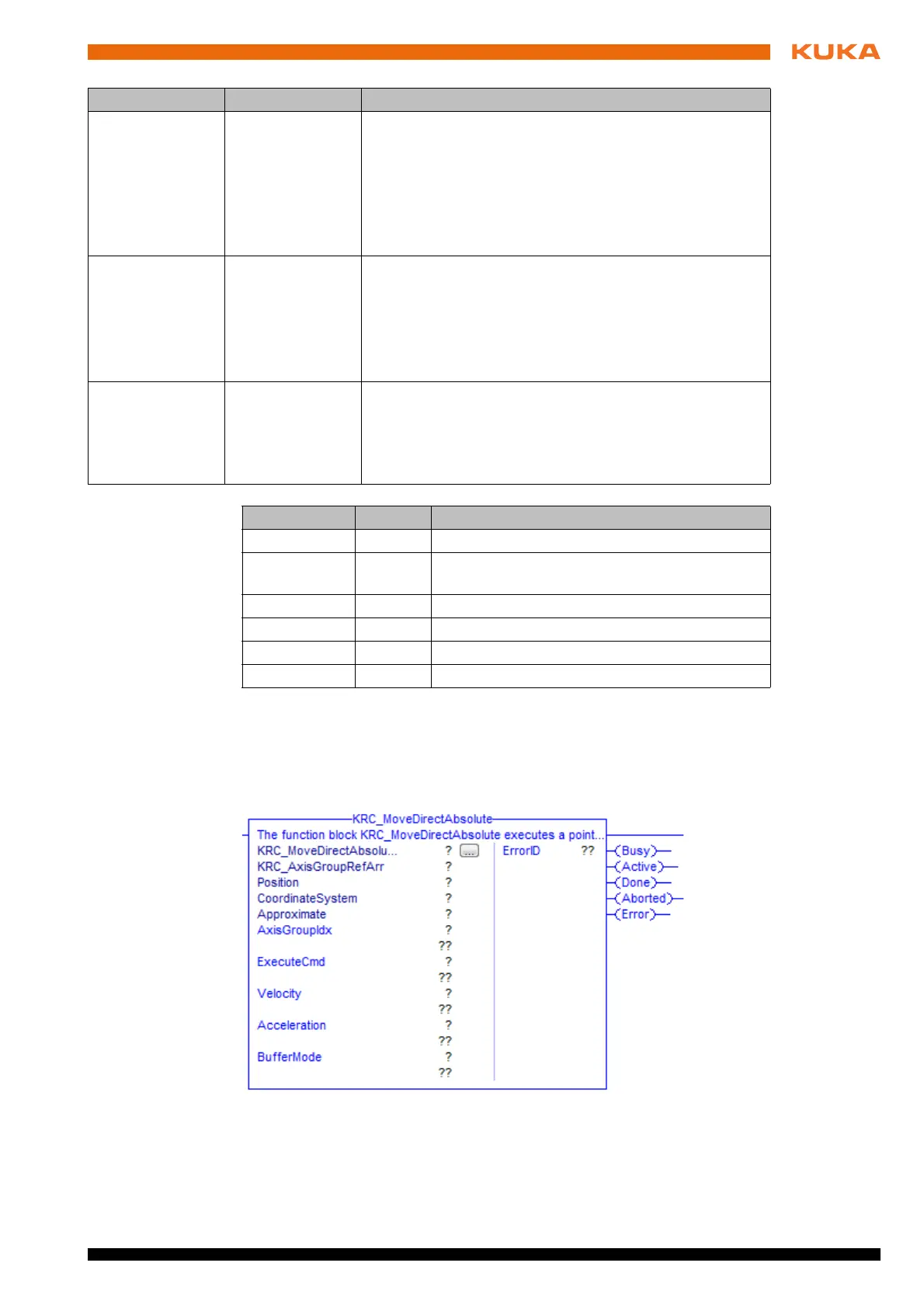

7.7.3 Moving to a Cartesian position with a PTP motion

Description The function block KRC_MoveDirectAbsolute executes a point-to-point motion

to a Cartesian end position. The coordinates of the end position are absolute.

Memory

Acceleration INT Acceleration

0 … 100%

Refers to the maximum value specified in the machine

data. The maximum value depends on the robot type and

the selected operating mode.

Default: 0% (= acceleration is not changed)

OriType INT Orientation control of the TCP

0: VAR

1: CONSTANT

2: JOINT

(>>> "OriType" Page 28)

BufferMode INT Mode in which the statement is executed

1: ABORTING

2: BUFFERED

(>>> "BufferMode" Page 27)

Parameter Type Description

Parameter Type Description

ErrorID DINT Error number

Busy BOOL TRUE = statement is currently being trans-

ferred or has already been transferred

Active BOOL TRUE = motion is currently being executed

Done BOOL TRUE = motion has stopped

Aborted BOOL TRUE = statement/motion has been aborted

Error BOOL TRUE = error in function block

Fig. 7-41: Function block KRC_MoveDirectAbsolute

Loading...

Loading...