KurzB‐SeriesOperationsGuide6–8

Flow Meter Configuration

Forexample,theSeries454PFTBmodelisdesignedtodirectlydriveasolenoid(upto12Wat24

VDC)toprovidethecompressedgascleaningtothesensor.FortheK‐BAR2000PB,onlyoneofthe

sensorcontrolboardsneedstohavethesolenoiddrivemodifications.Allunitsrespond

tothe

externaltriggercommandatthesametimeandmaskthepurgeblastfromtheoutputdata.

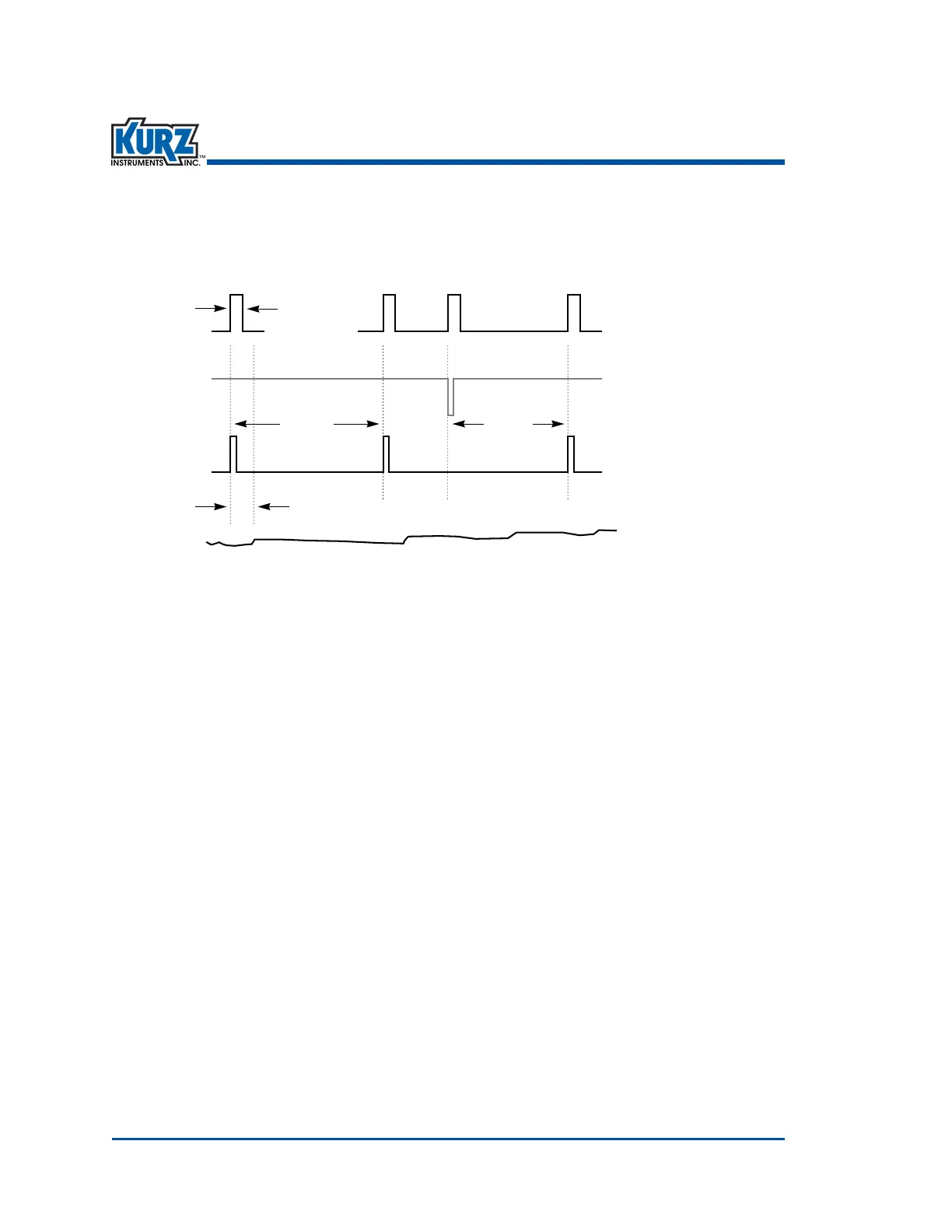

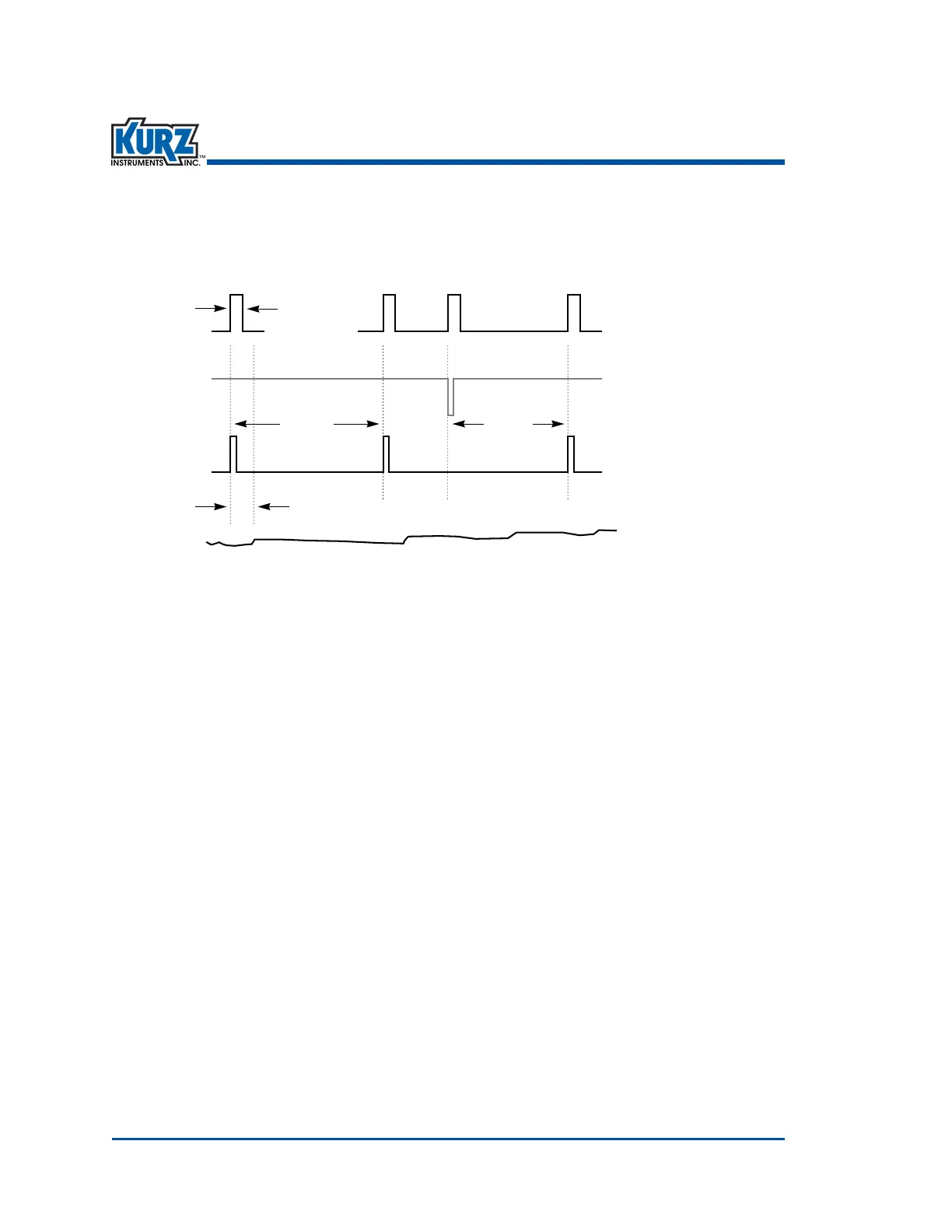

Figure 6‐1. Maskedpurgeblast

Wiring for the Purge Controller

Thepurgecontrollersetuprequiresconnectinga24VDC12WmaximumsolenoidtotheDO2or

solidstaterelaychannel#2.Pin#TB6‐1is+24VDCandTB6‐2istheGNDconnection.Seethefield

wiringdiagramforanexampleofthesolenoidwiring.Therecommendedwiring

gageis18 AWG

(1.02mm),althoughthegageandlengtharenotcriticalforthisconnection.

Note ThiswiringinformationonlyappliestothePurgeversionofthe

Series 454PFTB.

ThecontactclosureforactivatingthepurgeisonpinsTB6‐8ordigitalinput1(DI1)andground

(TB6‐6).Thewidthoftheactivationpulsemustbeatleast25 mslong,andthepurgewillstarton

theleadingedge(orfallingfromlogichightolow).

Purge

Output

Purge Start

Contact

Closure

Internal

Purge Timer

Flow Data

Output

Purge Time

Hold Time

Interval Interval

Loading...

Loading...