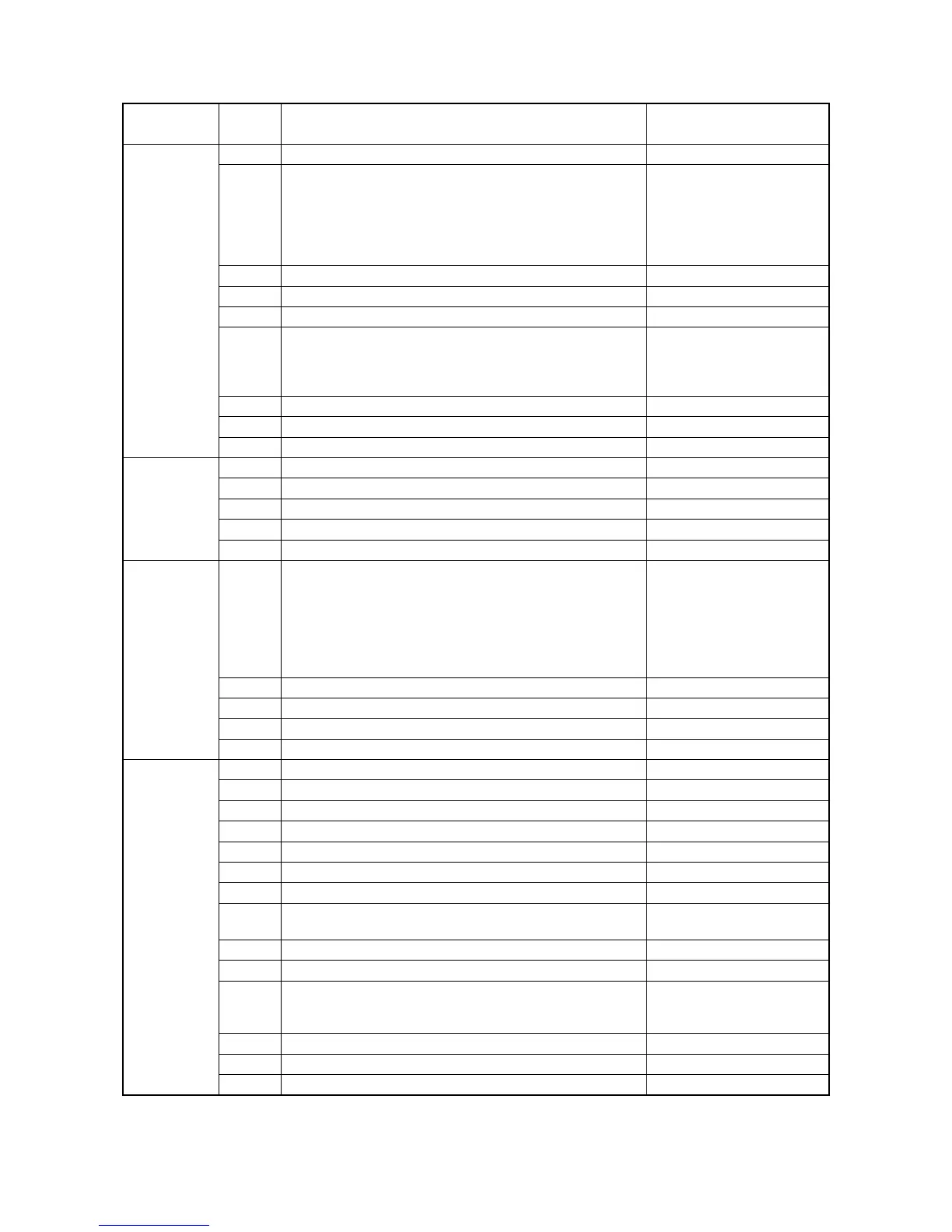

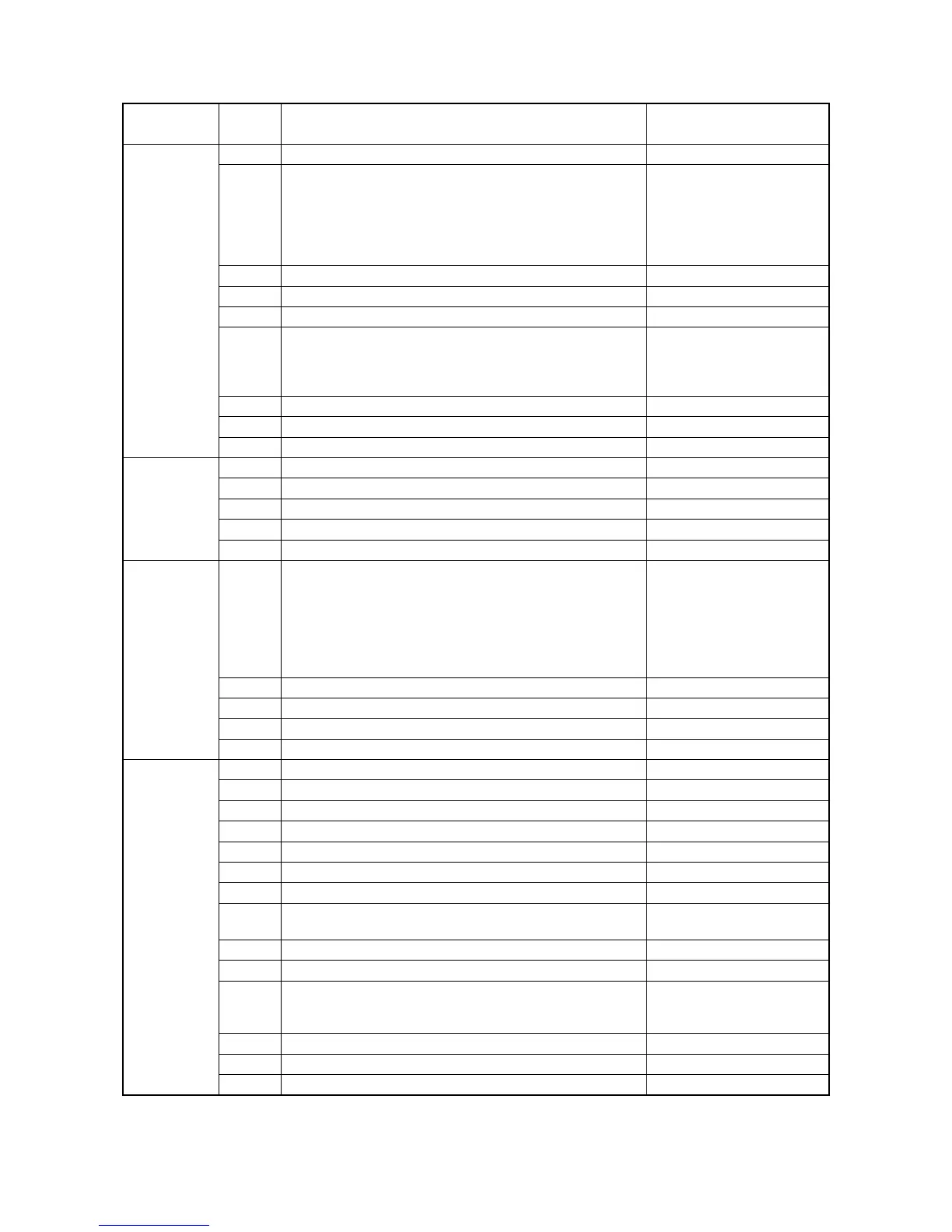

2GN/2GP/2GR-7

1-3-3

High voltage U100 Setting the main high voltage -

U101

Setting the other high voltages

Developing bias AC component frequency at image formation

Developing shift bias potential at image formation

Developing bias AC component duty at image formation

Transfer control voltage

Separation control voltage

28

*1

1

*1

50

*1

130

*1

20

*1

U102 Setting the cleaning interval for the main charger 5

*1,*2

U109 Displaying the drum type -

U110 Checking the drum count -

U112 Setting toner refresh operation

Time of toner refreshment

Developing bias on time

120

*1

700 (30 ppm)

*1

540 (40/50 ppm)

*1

U114

Setting separation charger mode

MODE1

*1

U117 Checking the drum number -

U118 Displaying the drum history -

Developing U130 Initial setting for the developing unit -

U144 Setting toner loading operation MODE2

*1

U150 Checking sensors for toner -

U157 Checking/clearing the developing drive time -

U158 Checking the developing count -

Fuser and

cleaning

U161 Setting the fuser control temperature

Driving start temperature when warm-up starts

Control temperature for displaying [Ready for copying.]

Control temperature during printing

175 (30 ppm)

*1,*2

185 (40/50 ppm)

*1,*2

190 (30 ppm)

*1,*2

200 (40/50 ppm)

*1,*2

190 (30 ppm)

*1,*2

200 (40/50 ppm)

*1,*2

U163 Resetting the fuser problem data -

U167 Checking/clearing the fuser counts -

U196 Turning the fuser heater on -

U199 Checking the fuser temperature -

Operation

panel and

support

equipment

U200 Turning all LEDs on -

U201 Initializing the touch panel -

U202 Setting the KMAS host monitoring system -

U203 Checking DP operation -

U204 Setting the presence or absence of a key card or key counter OFF/COUNTER

*1,*2

U206 Setting the presence or absence of the coin vender -

U207 Checking the operation panel keys -

U208 Setting the paper size for the paper feeder Inch specifications: Letter

*1,*2

Metric specifications: A4

*1,*2

U220 Setting the trial functions -

U223 Operation panel lock Unlock

*1,*2

U234 Setting punch destination Inch specifications: INCH

*1

Metric specifications:

EUROPE METRIC

*1

U236 Setting the limit for the ejection section of the built-in finisher OFF

*1,*2

U237 Setting finisher stack quantity 0/0

*1,*2

U240 Checking the operation of the finisher -

Section Item

No.

Content of maintenance item Initial

setting*

*Initial setting for executing U020, *1: The item initialized for executing U020, *2: The item initialized for executing U021

Loading...

Loading...