144 Hydraulic System

Refer to the hydraulic pressure table to adjust each function of the lifting arm. Before performing the

procedure, make sure that all function levers and their adjustment screws have been properly

identified on the valve.

NOTE: A helper may be needed when adjusting arm pressure. Use all necessary safety precautions

around the vehicle at all times.

To adjust the proportional valve main relief pressure:

1. Secure the arm working area using safety tape or barricades.

2. Install the lever on the proportional valve to adjust.

3. Move the lever back and forth to remove any residual hydraulic pressure in the system.

4. Connect a 0–4000 psi gauge on the quick coupler located on the proportional valve.

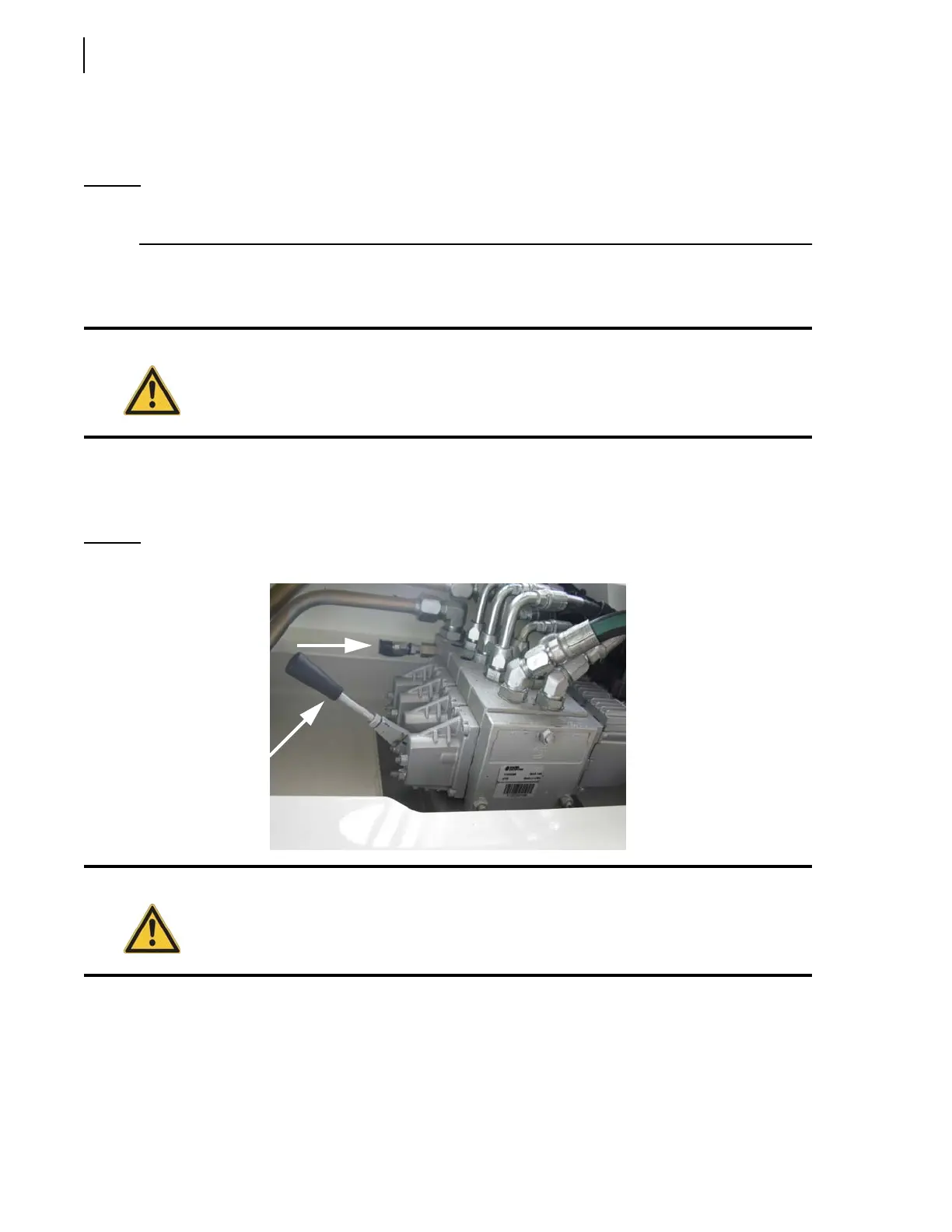

Figure 5-22

Control lever and quick coupler

5. Start the engine and engage the hydraulic system.

6. Retract and maintain the arm to the end of its stroke using the lever.

7. Adjust the main relief valve to 2000 psi (2700 psi in case of a 300-gallon gripper) using the

adjustment screw. Turn the hex wrench clockwise to raise pressure, or counterclockwise to lower

pressure.

Warning!

Stay out of the path of the arm while manually moving the Right Hand™.

Failure to do so may result in severe injury, or even death.

Warning!

Make sure that the ball valve on the suction line is completely open before starting the

engine. Failure to do so may damage the hydraulic system.

Loading...

Loading...