General Maintenance 55

Finishing Up Replacing Sliding Shoes and Floor Guides

Apply the following procedure to finish up replacing the sliding shoes and floor guides:

1. Run the packer a few times.

1 a. If the packer is binding, apply some primer paint on the floor guide to find out where the

rubbing is occurring.

1 b. Run the packer a few times again. The location where the paint has come off indicates the

surface that needs to be grinded.

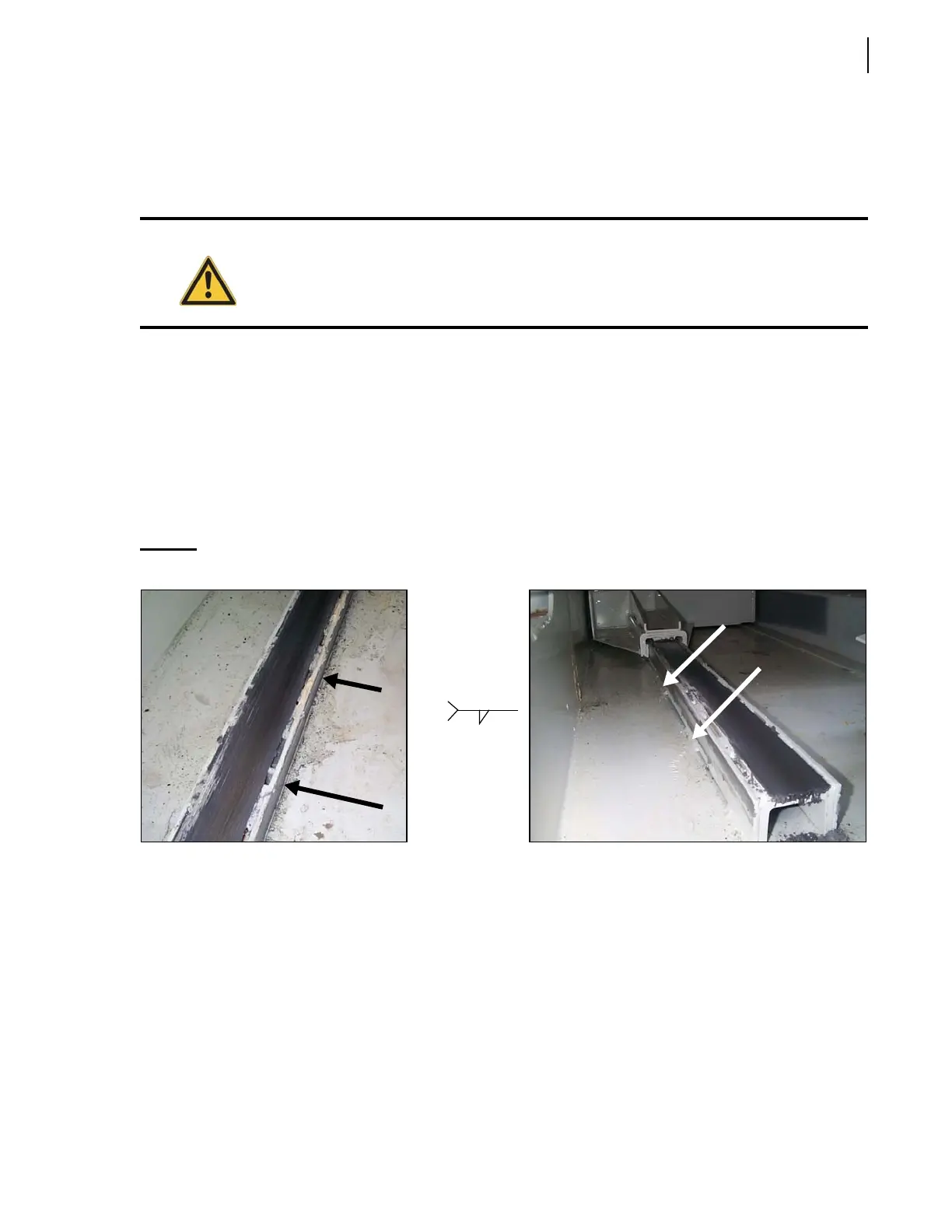

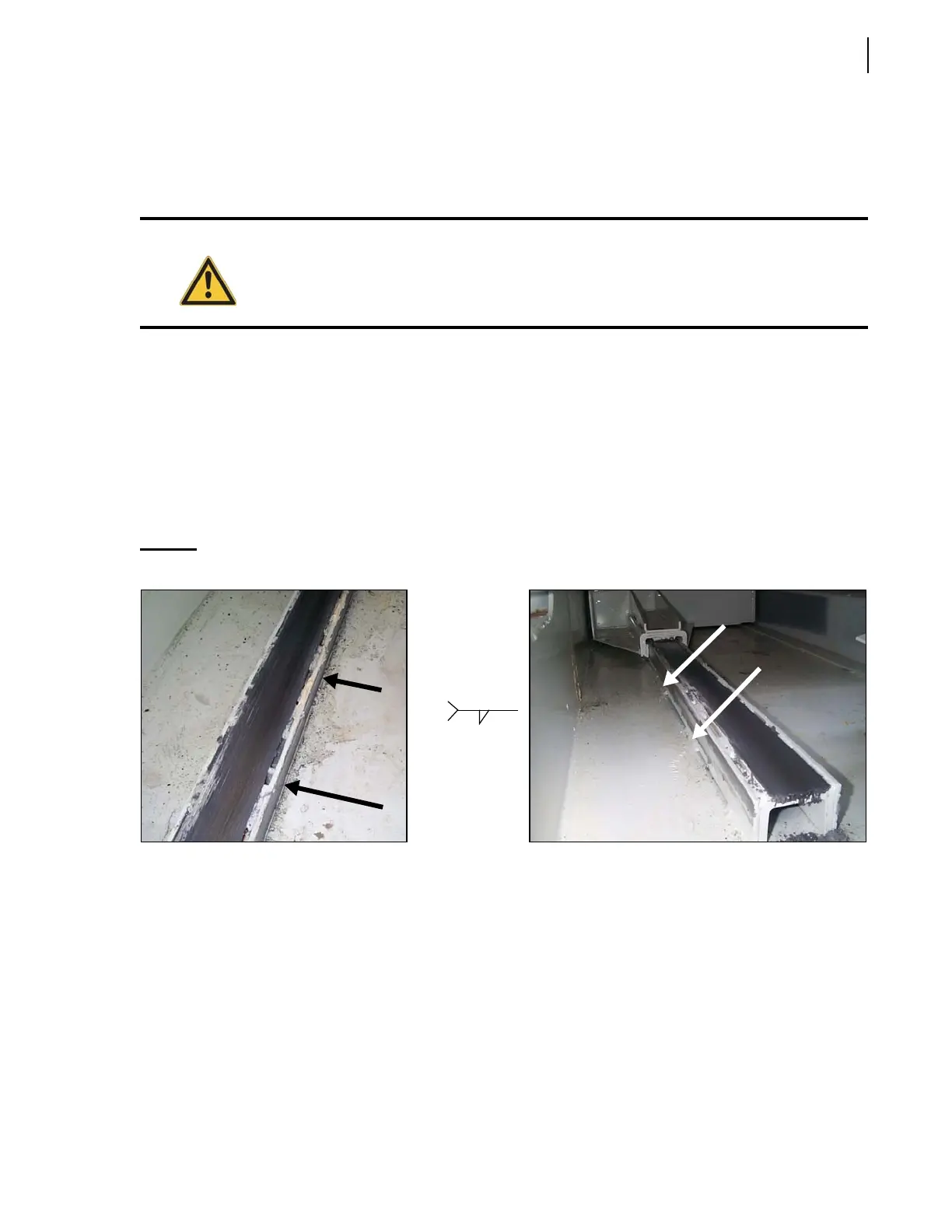

2. If the packer slides properly, weld the floor guides to the floor as illustrated in Figure 3-46.

3. Fully extend the packer to finish welding behind it.

4. Remove the temporary steel tubes installed in Step 7 on page 52.

5. Spray grease on the floor guides for preventing premature corrosion and wear.

Figure 3-46

Welds on both sides of floor guide

Floor Guides

Floor guides wear out over time, so their replacement is necessary for the packer to continue

operating properly. Usually, replacement of floor guides is done at the same time when sliding shoes

are replaced.

When sliding shoes need to be replaced because of wear, chances are floor guides need replacement

too. To replace floor guides, apply the procedure detailed in the “Replacing Sliding Shoes” section on

page 52. This procedure includes steps to remove and replace floor guides.

Danger!

Never enter the hopper while the packer is moving.

FCAW

3-123 ⁄ 8 ˝

Loading...

Loading...