224 Lifting Arms

Adjusting Up/Down Holding Valve Pressure

NOTE: The up/down cylinder on a standard lifting arm has no holding valve on it. However, it has a

pressure relief cartridge that provides stroke-end cushioning during extension of the cylinder.

The up/down cylinder on a HD lifting arm is fitted with a holding valve as well as a cushioning

adjustment screw which is used to adjust the stroke-end cushioning during extension/

retraction of the cylinder.

NOTE: If the cushioning effect needs to be adjusted, simply turn the cushioning adjustment screw

accordingly: clockwise to increase cushioning effect; counter-clockwise to reduce it.

To adjust the up/down holding valve pressure:

1. Apply all safety measures to ensure safety around the vehicle at all times.

2. Make sure that the parking brake is applied.

3. Locate the holding valve on the up/down cylinder (see Figure 10-20).

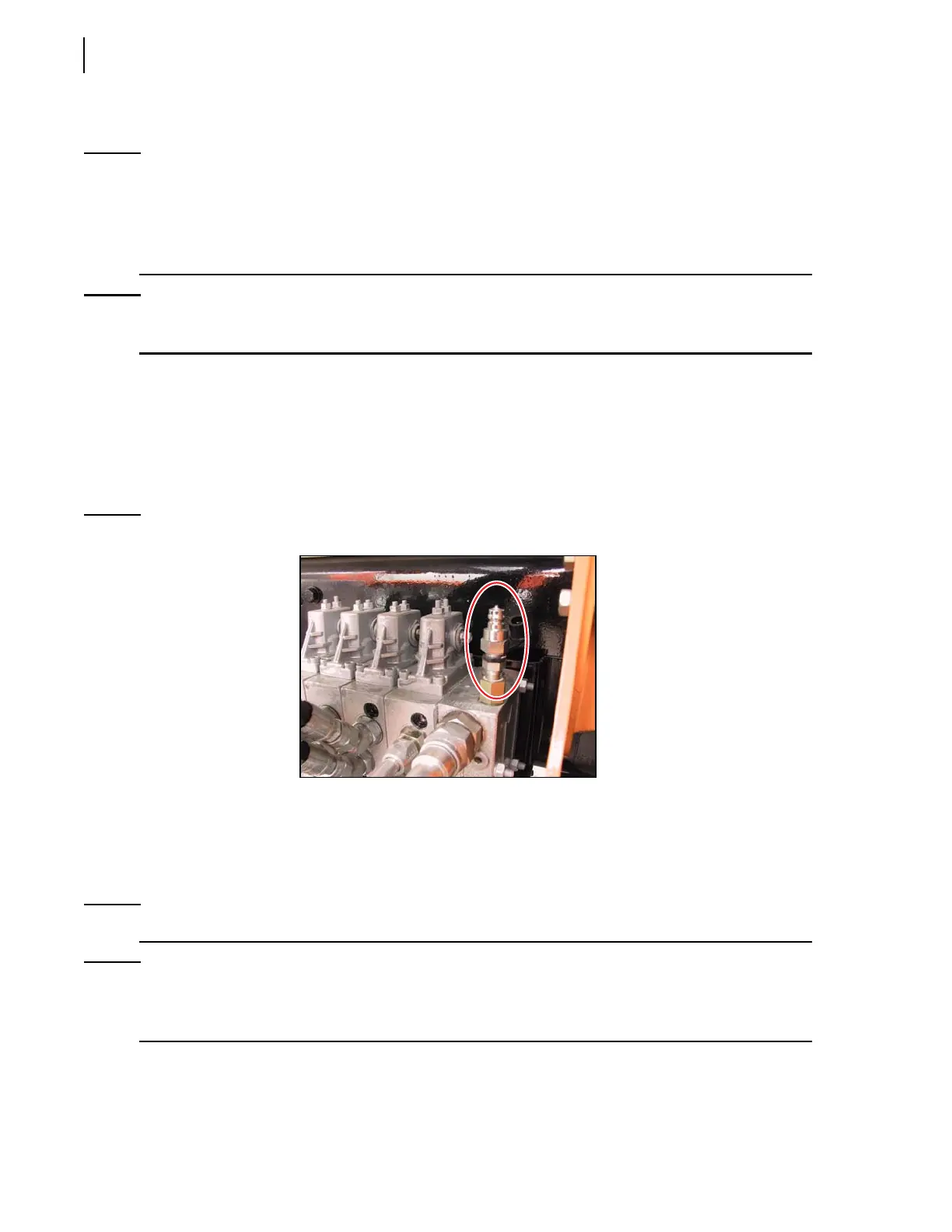

4. Connect a pressure gauge to the automated arm valve.

Figure 10-19

Quick coupler for pressure gauge

5. Start the engine and engage the hydraulic pump.

6. Using a lever on the valve, manually raise the Right Hand™ arm gradually.

7. If the gauge does not indicate a pressure of about 700 psi when the automated arm starts going

down, adjust the up/down holding valve adjustment screw to set the pressure properly.

NOTE: Turn the screw counter-clockwise to increase pressure or clockwise to reduce pressure.

NOTE: This pressure value of 700 psi is a reference value; it could be more or less. It all depends on

how much pressure the up/down holding valve needs to resist to a downward pulling force of

at least 1000 lbs.

Loading...

Loading...