180 Troubleshooting

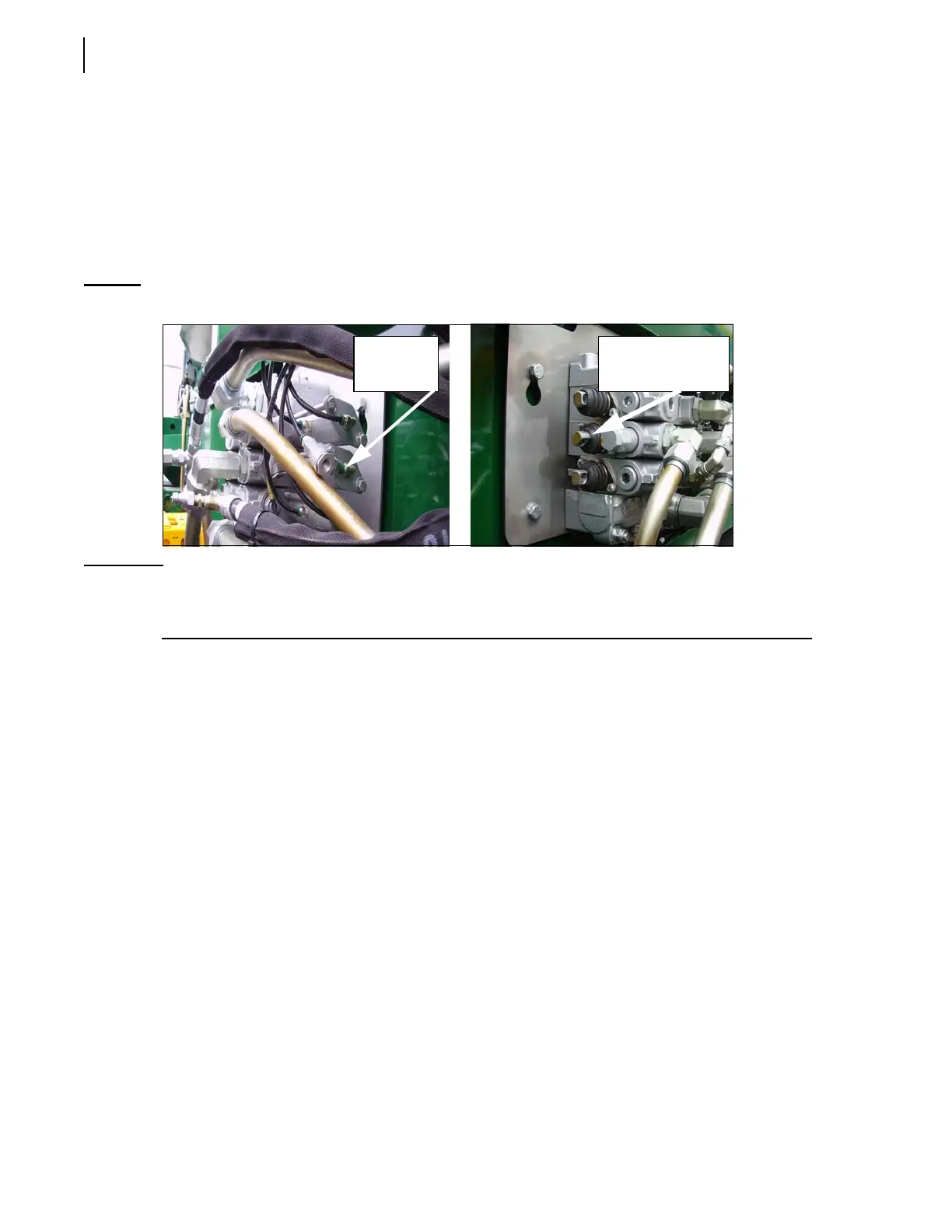

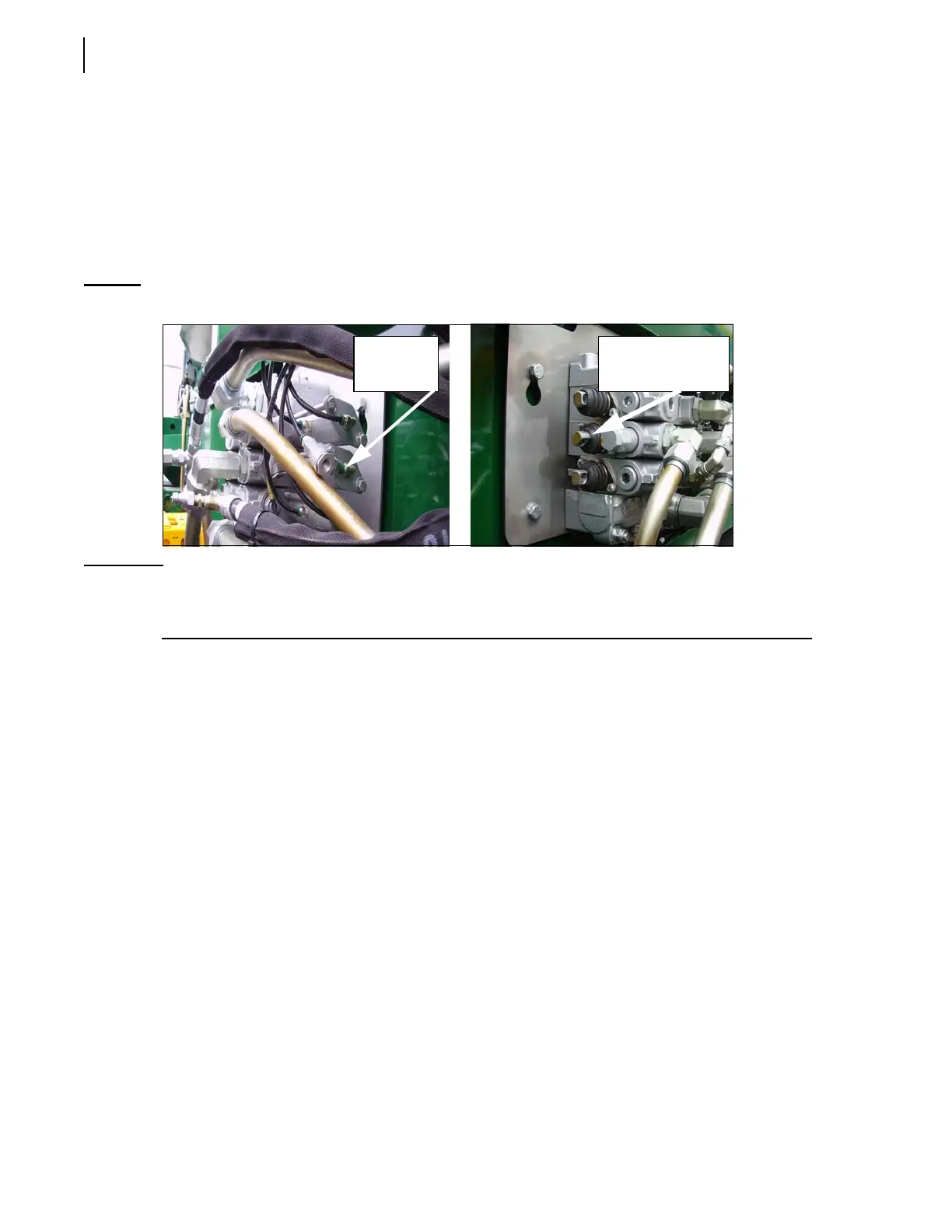

4. Inject compressed air on one side of the actuator to ensure that the spool moves freely inside the

valve (the same process will have to be done for the other side of the actuator).

• If the spool is not moving freely, lubricate or replace the air actuator.

• If the spool is moving freely, try injecting air in the tube and see if air is exiting from the quick

exhausts valves, close to the packer valve section actuator.

• If not, check that air lines are not blocked or bent, and, if necessary, replace the quick exhaust

valves.

Figure 8-7

Injecting compressed air

IMPORTANT: If air is leaking by the opposite port of the pressurized side of the actuator when both hoses are

removed, this could indicate that the o-ring on the air actuator piston is leaking. If needed

disassemble, clean, and lubricate with grease, or replace the o-ring.

Hydraulic spool

should move back

and forth.

Inject

compressed

air

Loading...

Loading...