CHAPTER 3: SETTING INTO OPERATION 21

MOVE S2

The bar feeder MOVE S2 is delivered totally assembled. Because of this, it is possible to proceed directly

to its alignment when in place behind the lathe.

Before proceeding with the alignment of the bar feeder, ensure that the lathe is stable and

preferably leveled. The bar feeder must be placed as close as possible to the lathe's

spindle.

The alignment may be carried out using a nylon string, an optical tool, etc. If you do not have any

alignment tools, contact LNS or its local representative so they may take care of the bar feeder

installation.

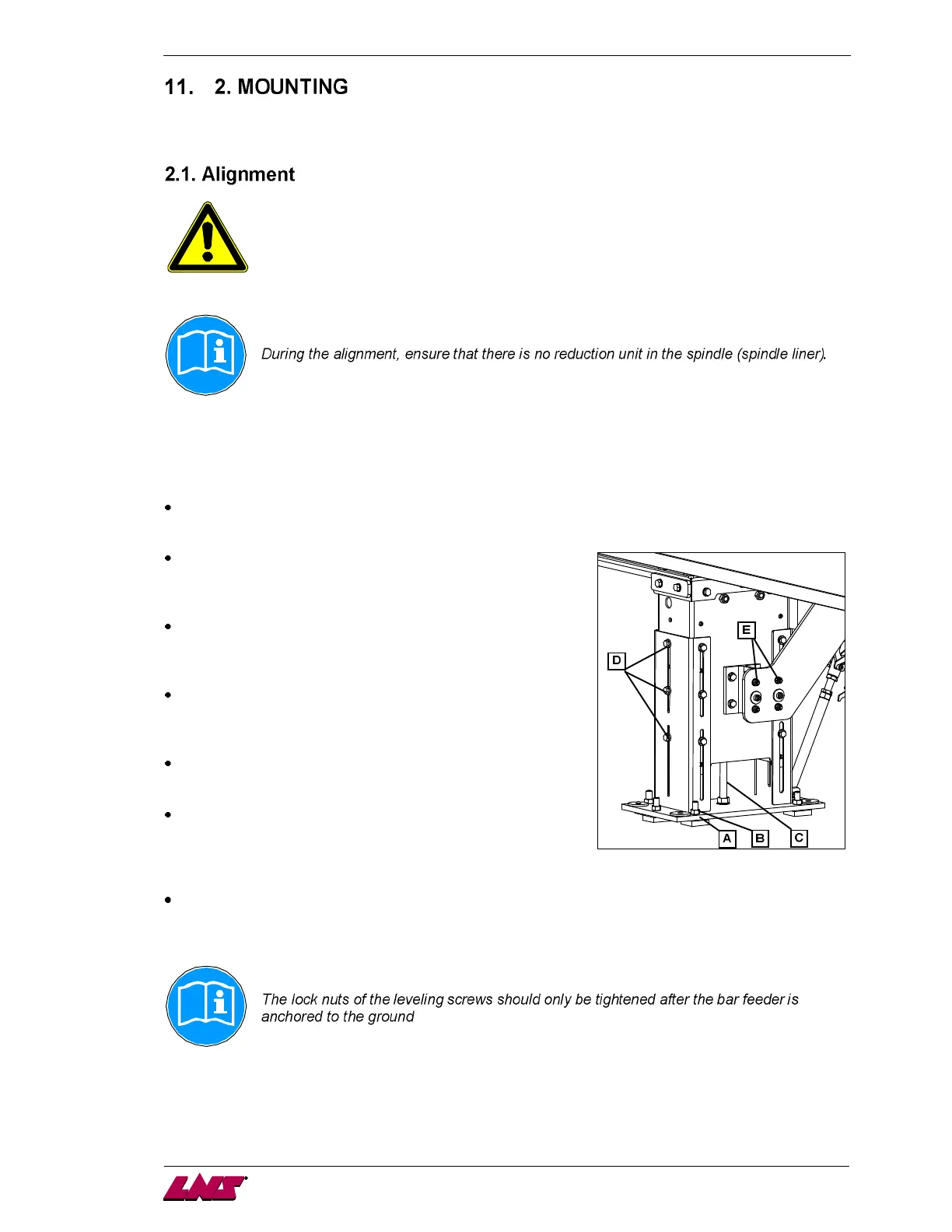

On each foot, loosen the lock nuts (A) of the leveling screws (B). Then, make sure that the weight of

the bar feeder is evenly distributed over the 12 support points.

Loosen the nuts and locking screw (D) and make sure

that the central screws (C) of the front and rear feet are

supported.

Open the guiding channel and place the level crosswise

on the lower part. Adjusting the screws (B), set the lateral

level.

Adjusting the central screws (C), set the height of the bar

feeder. Normally, when the reference point is known, this

adjustment is done at the factory.

Don't forget to adjust the supporting screws of the bar

magazine (E).

Together with the vertical alignment, proceed with the

lateral alignment, by shifting the apparatus. If you don't

have the needed material to perform this operation,

please contact LNS or its local representative.

When the alignment is satisfactory, tighten all locking screws (D). Check the alignment and, if

necessary, correct it with the screws (B).

.

Loading...

Loading...