CHAPTER 4: OPERATION 47

MOVE S2

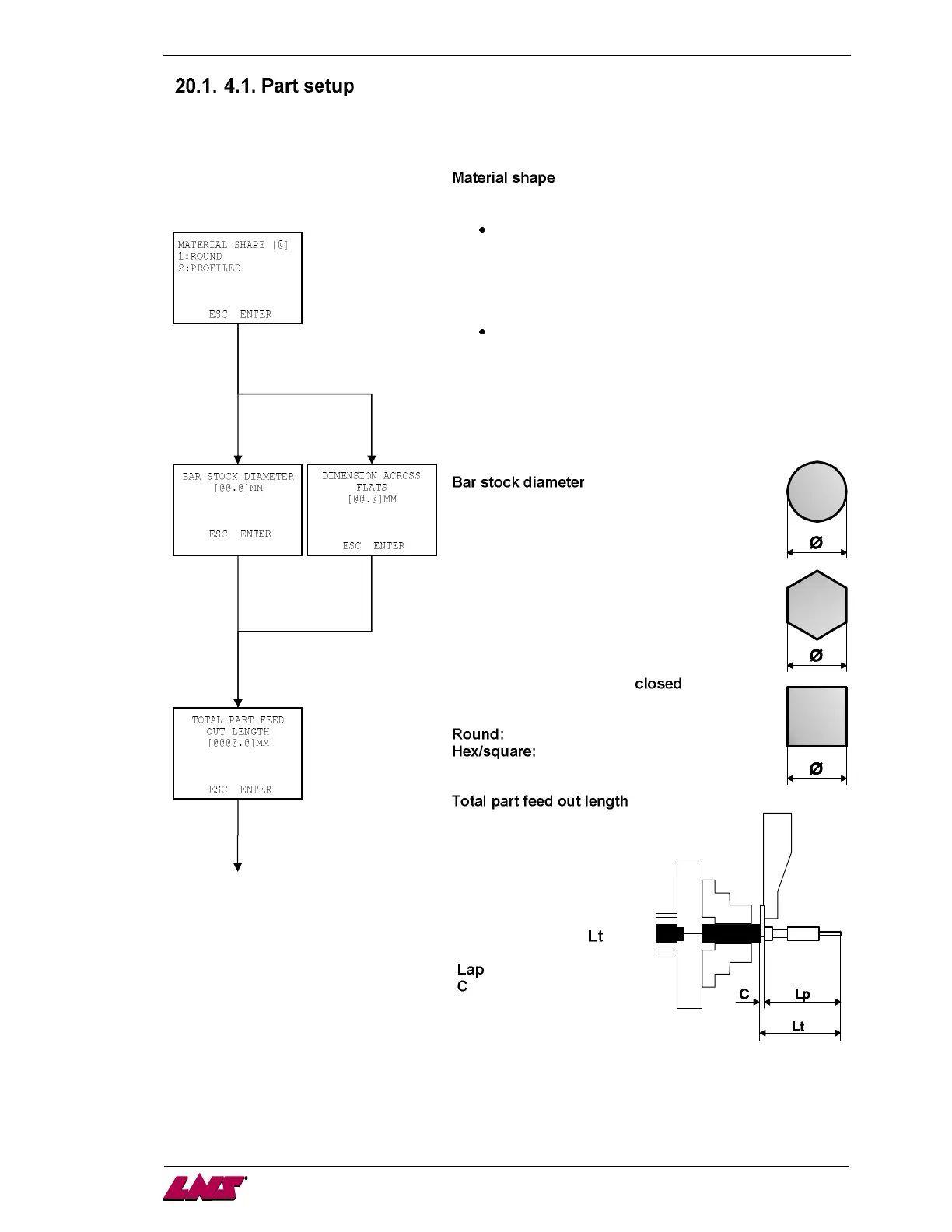

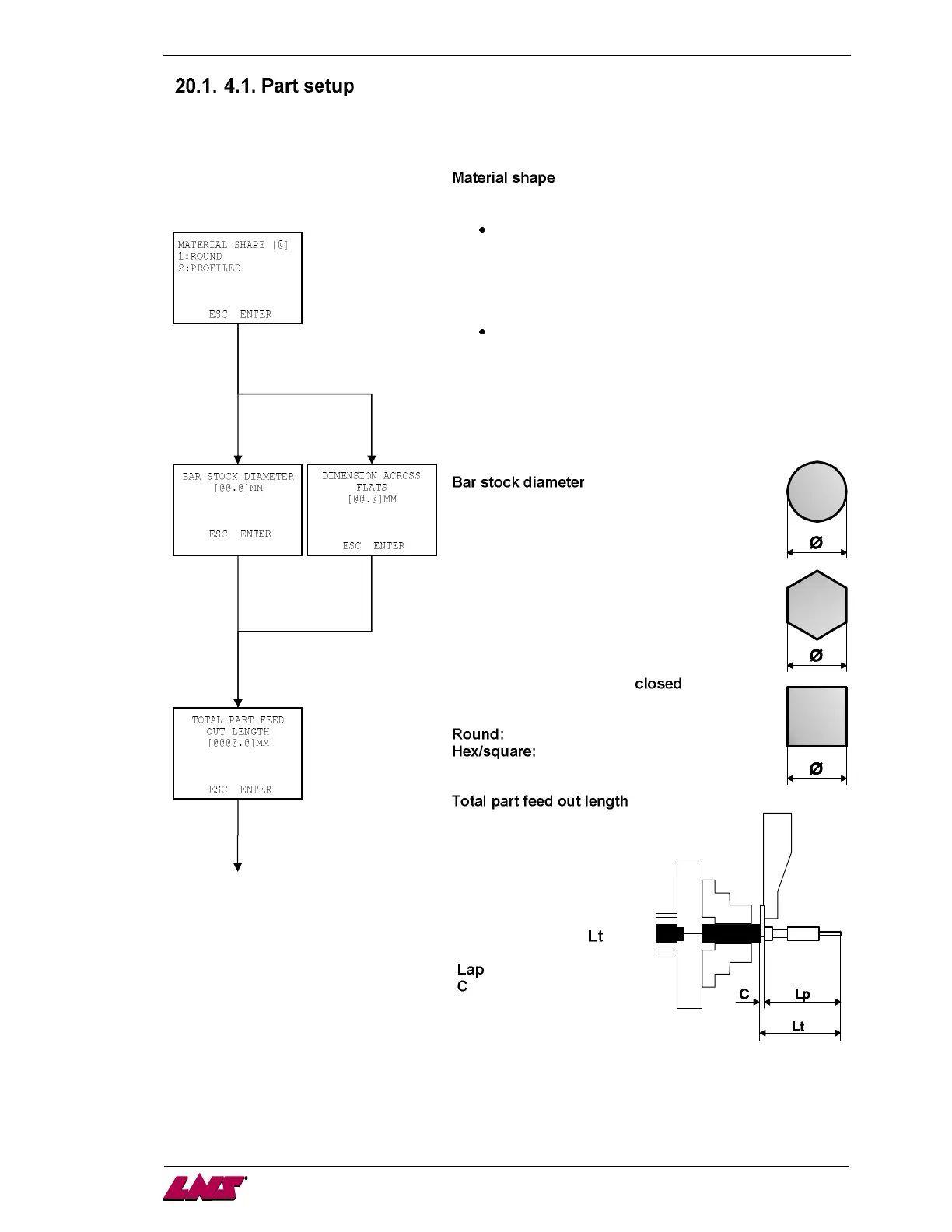

All handling, adjustments, and settings that need to be done on the bar feeder for executing a part are

included in the start-up. This section presents a brief explanation of the start-up parameters of the bar

feeder.

If parameter 2 is selected:

When the material is profiled, the bar feeder will try

several times (for 2 minutes), to position the bar

inside the clamping device of the lathe. The

accuracy of the positioning is also assured by a

positioning procedure designed specifically for

profiled bars.

The setting of the loading table and of the fingers

changes. This setting is automatically done by

motor M3.

As soon as parameter 1 is selected, the M3 motor

automatically repositions the table and the fingers in

standard position.

It is important, at each change in start-up, that

the diameter of the new bars that the bar feeder

will load is updated in the parameters.

The PLC, therefore, takes this into account and

adapts the torque of the pushers. A greater

precision of positioning can therefore be

guaranteed. Moreover, small diameter bars will

not bend under the pressure of the pusher.

The value of the diameter entered will

automatically determine the

position of

the front rest jaw.

outer diameter

dimension across flats

The servomotor is precise

enough to feed the part

during the opening of the

clamping device of fixed

headstock lathes.

The feed-out length (

)

includes the part length

(

), the cut-off tool width

(

) and the face-off length.

Loading...

Loading...