48 CHAPTER 4: OPERATION

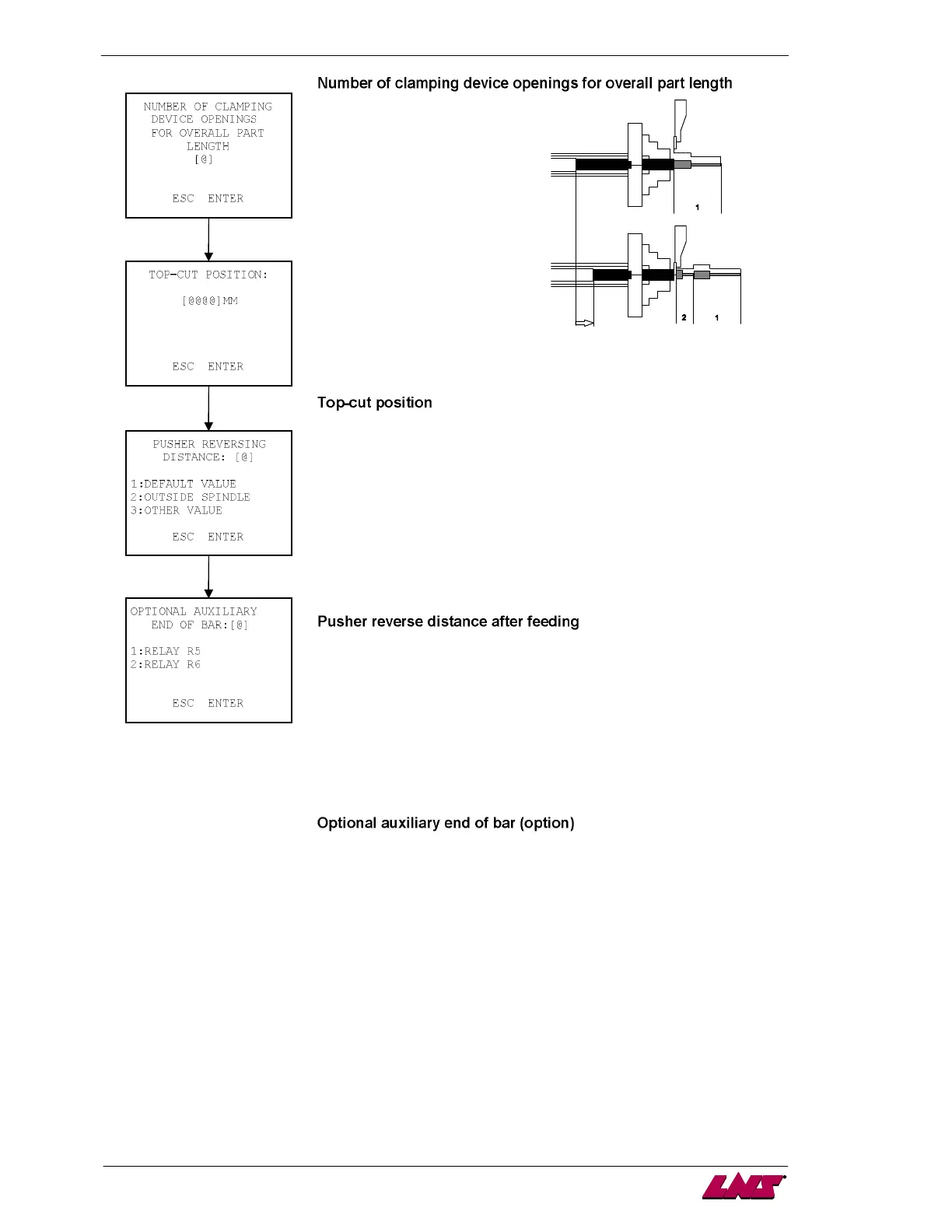

MOVE S2

When the machining of a part

requires several openings of the

clamping device (for ex.: a long

part, or transfer of the part to the

sub-spindle), some interface

conflicts may occur during the

feeding process.

It is important for the bar feeder to

be “informed” of the number of

times the clamping device must

open for the machining of a part.

The bar feeder only carries out the first positioning for a single part.

The following positioning (if any) must be done by the turret.

During the loading cycle, the bar is automatically loaded and positioned

into the spindle, outside the clamping device of the lathe (chuck or

actuator).

This positioning corresponds to a value (Z) programmed by the

operator, which is equal to the distance between the measuring cell

and the position of the material in the lathe clamping device.

With this system, the setting is the same for any bar length. Further

information in the chapter 4. Operation, point 3.4.4.2.

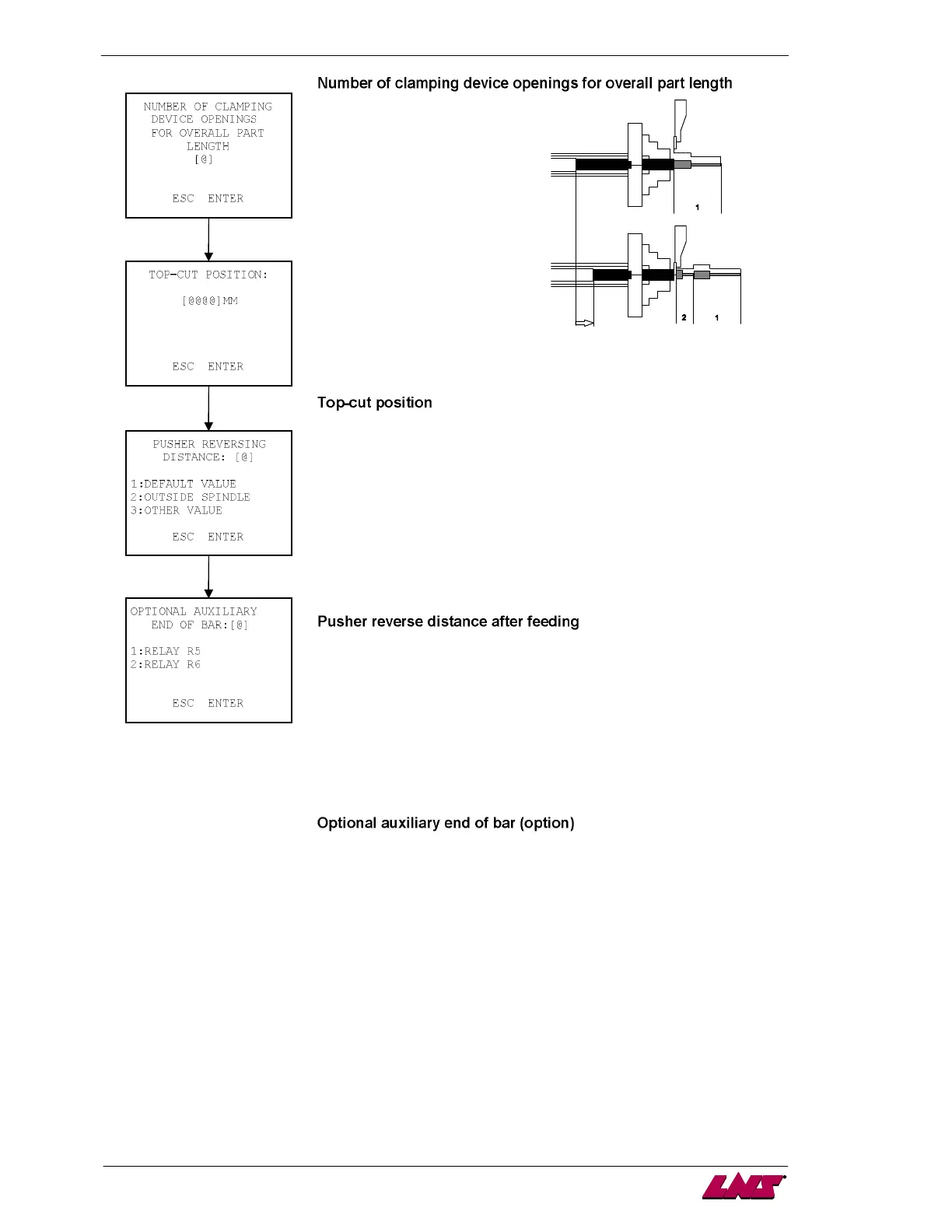

In production cycle, each time the clamping device of the lathe closes,

the feeding pusher moves backwards so as not to come into contact

with the rotating bar. The value of the reverse distance is set at 4 mm

at the factory.

1. Default value (4 mm)

2. Outside of the spindle

3. Enter the desired value

When machining remnants (A) that are rather long, a second mode of

production for machining the rest of the stock can be selected

(depending on the capabilities of the lathe).

Loading...

Loading...