214880 84 Revision A

NOTE:

Right discs (A) and left discs (B) are slightly offset as shown, depending on which idler gear the spindle is turning.

• Spindles that rotate clockwise have left-leading threading

• Spindles that rotate counterclockwise have right-leading threading

DANGER

To avoid bodily injury or death from unexpected start-up or fall of a raised machine, stop engine, remove key, and

engage windrower lift cylinder safety props before going under machine for any reason.

CAUTION

Discblades have two sharp cutting edges that can cause serious injury. Exercise caution and wear gloves when working

with blades.

1. Park on a flat, level surface.

2. Lower the disc header fully, shut off engine, and remove key.

NOTE:

To prevent oil from spilling from the cutterbar while installing disc spindles, ensure the disc header is on a flat, level

surface, and is tilted all the way back.

3. Determine suitable spindle rotation pattern for crop conditions. Refer to 4.5.3 Replacing Cutterbar Spindles, page 80.

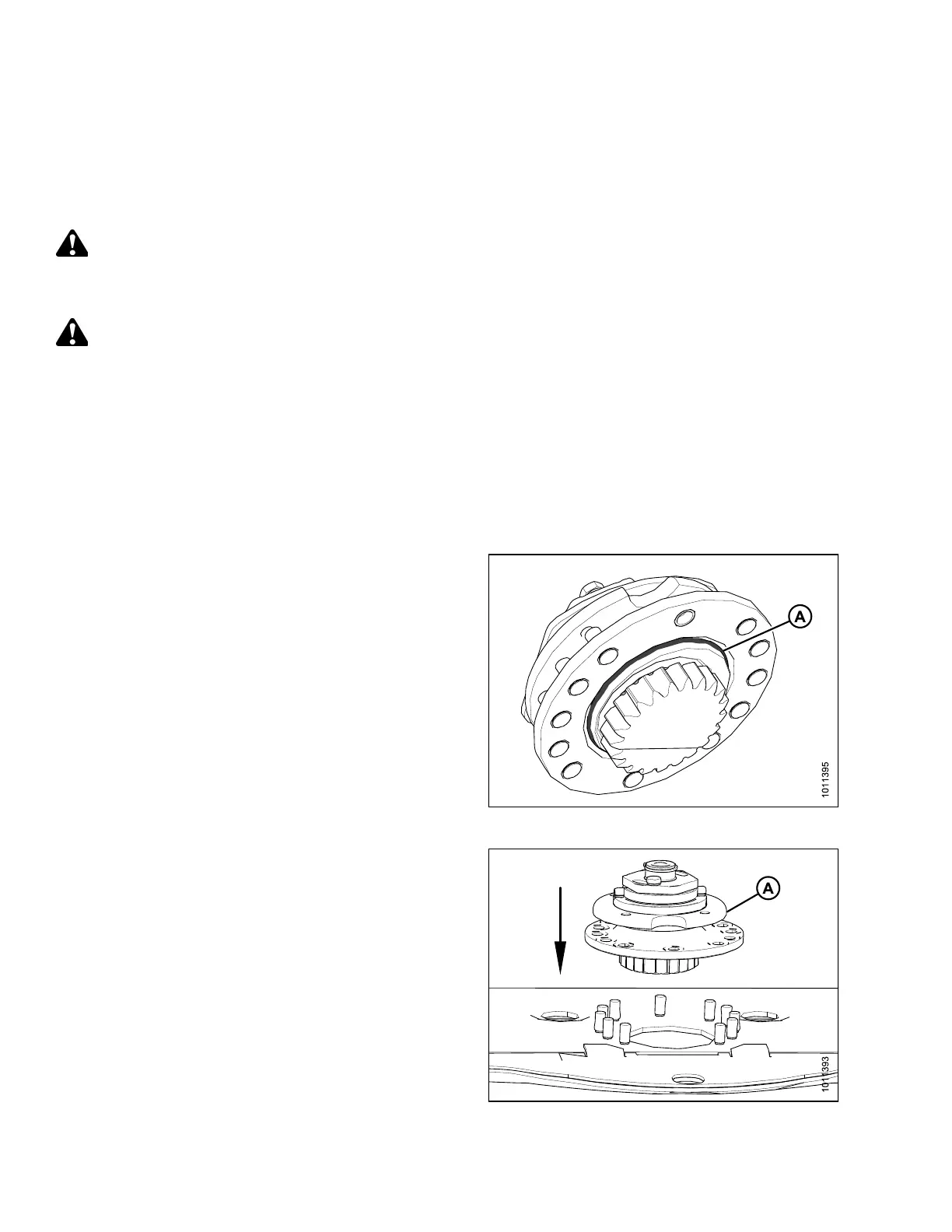

Figure 4.35: Left Spindle O-Ring

4. Ensure that spindle O-ring (A) is properly seated, cleaned,

and undamaged.

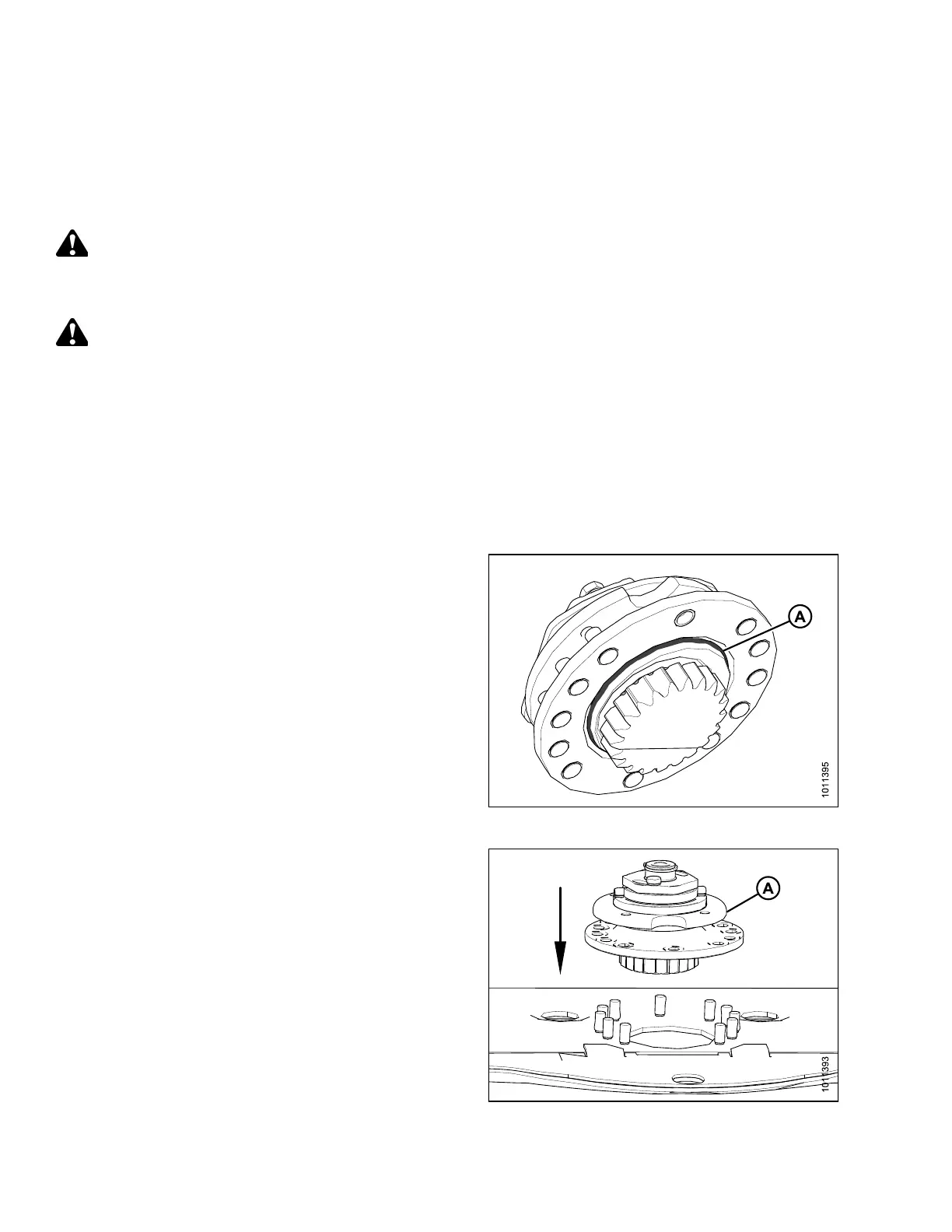

Figure 4.36: Left Spindle

5. Insert spindle (A) into cutterbar.

MAINTENANCE AND SERVICING

Loading...

Loading...