214880 158 Revision A

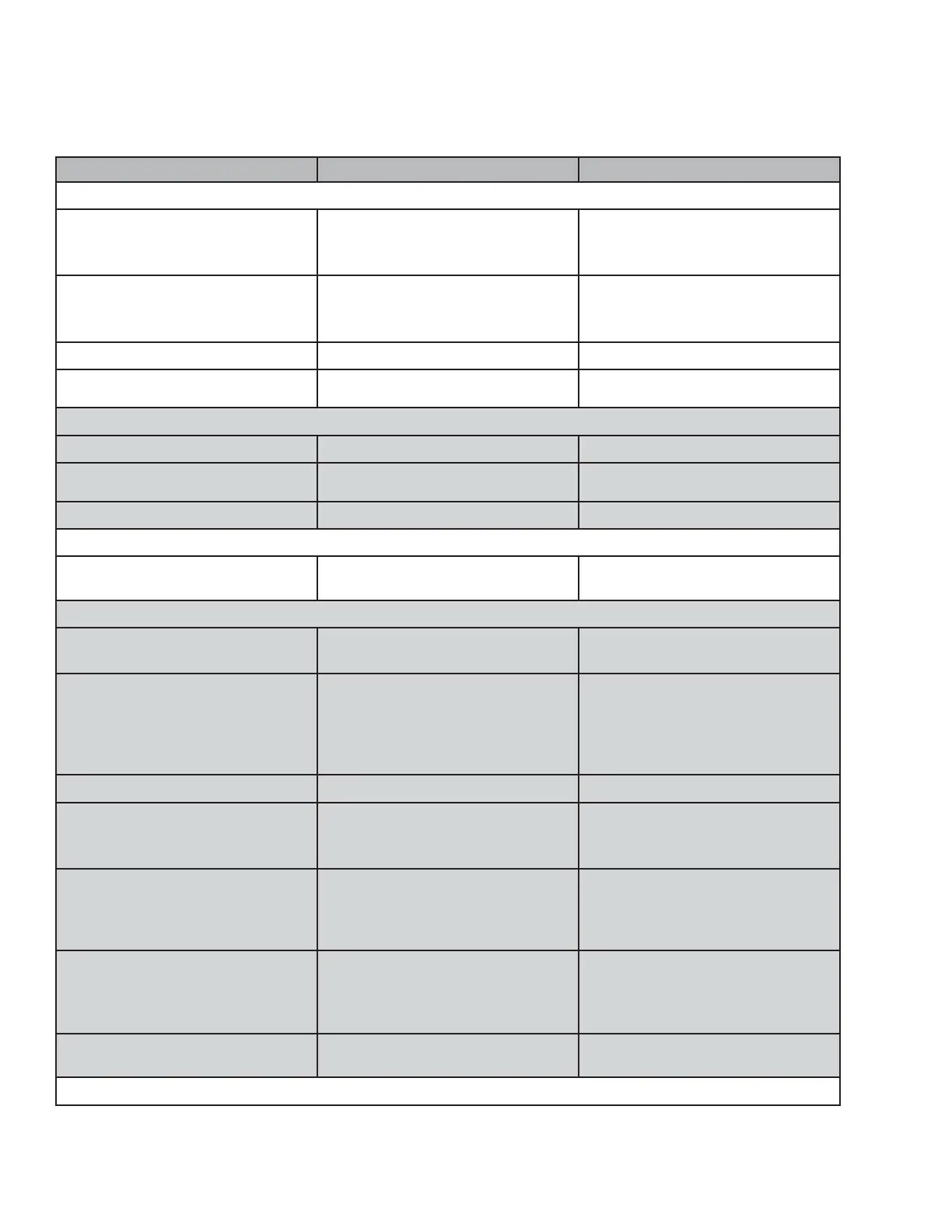

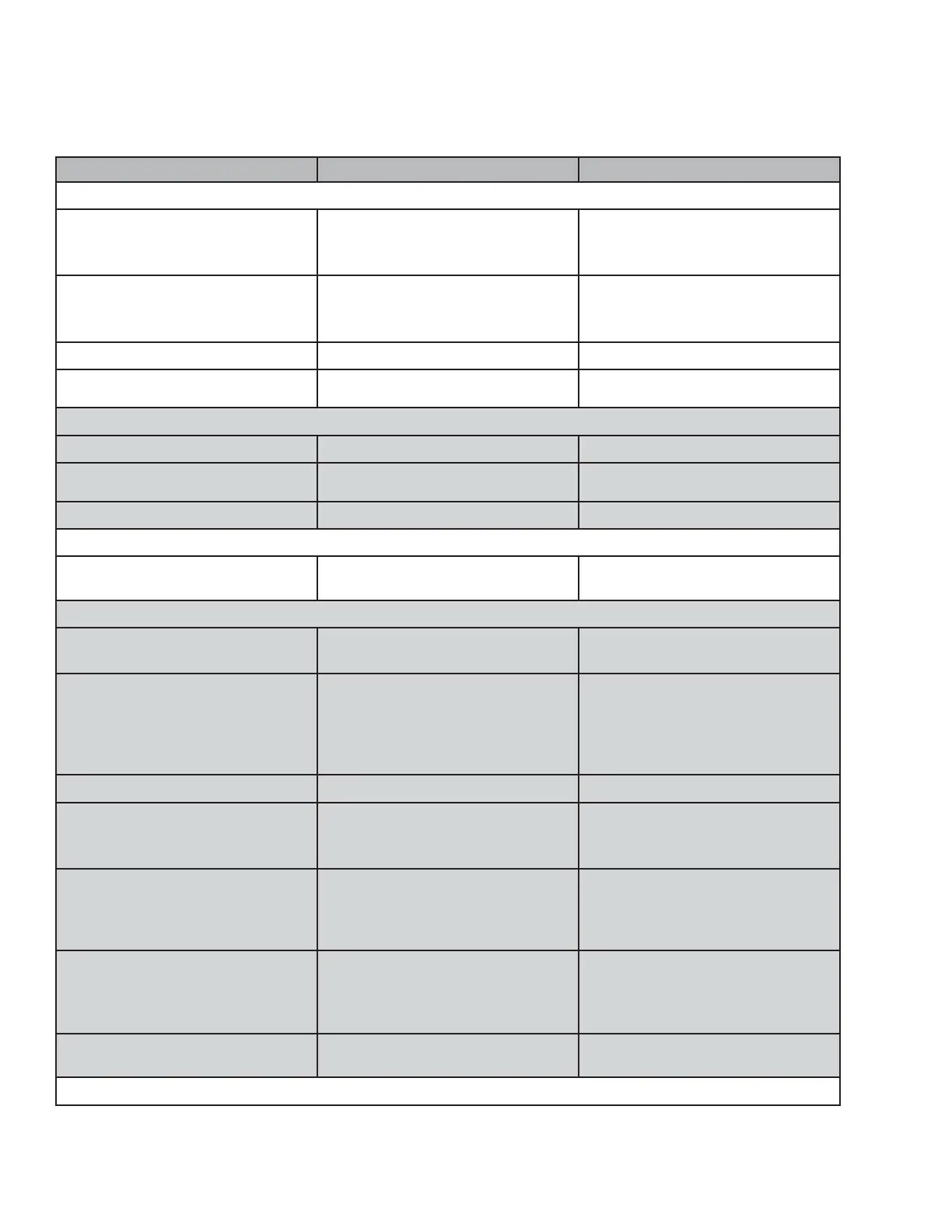

6.2 Mechanical Problems

Problem Solution Refer to

Symptom: Excessive noise

Bent discblade Replace blade.

• Removing Discblades, page 90

• Installing Discblades, page 92

Conditioner roll timing off

Check roll timing and adjust if

necessary.

• Checking Roll Timing, page 51

• Adjusting Roll Timing, page 51

Bent drum deflector Replace drum.

4.5.7 Maintaining Drums, page 100

Conditioner roll gap too small Check gap and adjust if necessary.

• Adjusting Roll Gap, page 49

Symptom: Excessive vibration or noise in header

Mud deposits on conditioner rolls Clean rolls.

—

Conditioner rolls contacting each other Increase roll gap.

• Adjusting Roll Gap, page 49

Conditioner rolls contacting each other Check roll timing. Checking Roll Timing, page 51

Symptom: Excessive heat in cutterbar

Incorrect level of lubricant in cutterbar

—either too little or too much

Drain lubricant and refill with specified

amount.

Draining the Cutterbar, page 74

Symptom: Frequent blade damage

Mud on cutterbar

Remove mud from cutterbar. Do NOT

allow mud to dry on cutterbar.

—

Spindle bearing failure

Replace spindle bearing.

• Removing Cutterbar Spindles,

page 81

• Installing Cutterbar Spindles, page

83

Header float set too heavy Increase float. Refer to windrower operator’s manual

Material wrapped around spindle Remove disc and remove material.

• Removing Discblades, page 90

• Installing Discblades, page 92

Cutting too low in rocky field

conditions

Decrease header angle, increase float.

• 3.8.1 Cutting Height, page 44

• Refer to windrower

operator’s manual

Ground speed too high in rocky field

conditions. At high ground speed,

header tends to dig rocks from ground

instead of floating over them

Reduce ground speed.

—

Discblades incorrectly mounted

Check all blade mounting hardware

and ensure blades are free to move.

Inspecting Discblade Hardware, page

89

Symptom: Excessive wear of cutting components

TROUBLESHOOTING

Loading...

Loading...