HYDRAULIC SYSTEM TMS800E SERVICE MANUAL

2-66

Published 01-29-2014, Control # 496-00

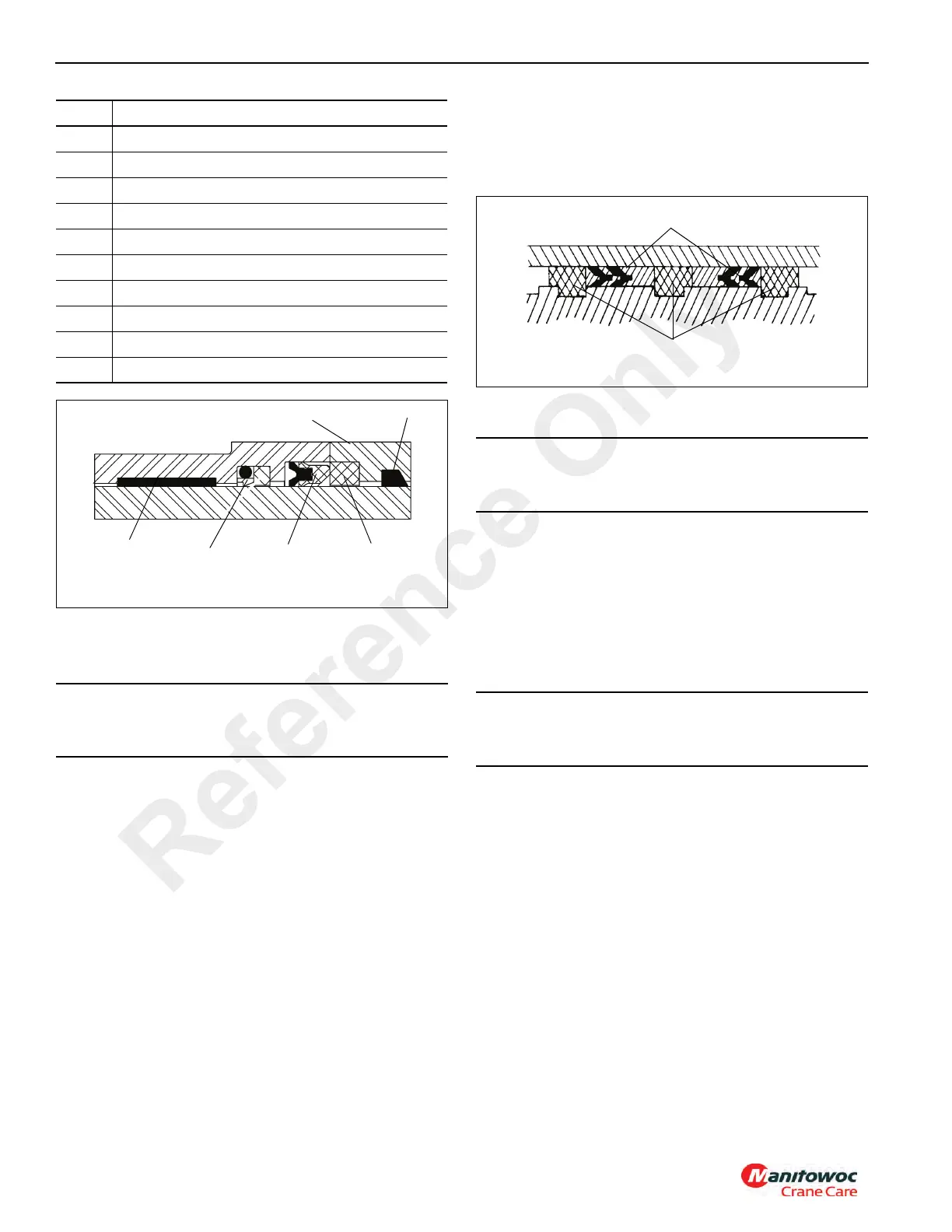

5. Install the retaining ring and head onto the cylinder rod.

6. Install the spacer onto the cylinder rod.

7. Install the O-ring and backup rings into the inside of the

piston.

NOTE: Use a new setscrew.

8. Screw the piston onto cylinder rod and secure with a

new setscrew.

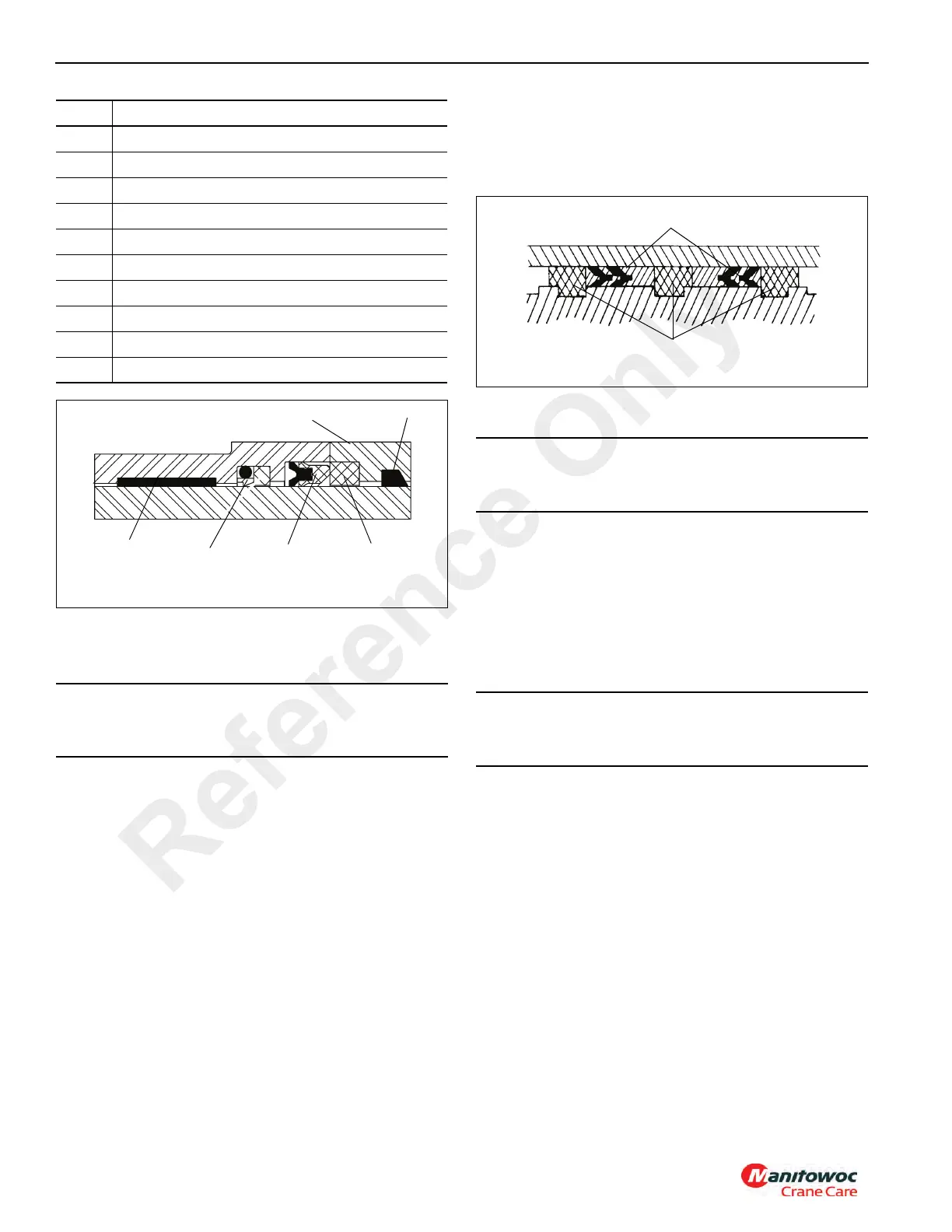

9. Install the guide lock rings and hydrolock seals onto the

outside of the piston, see Figure 2-47.

10. Install the wear ring on the outside of the spacer.

11. Clean all oil from the threads of the cylinder head and

apply Loctite #290 to the threads.

12. Lubricate the piston and head with clean hydraulic oil

and install the rod assembly into the cylinder barrel with

a slight twisting motion.

13. Using a chain wrench, secure the cylinder head and

retaining ring to the cylinder barrel.

14. Pressurize and cycle the cylinder with hydraulic oil

pressure. Test the cylinder at 331 bar (4800 psi). Check

for proper operation and any leakage. Make repairs as

needed.

15 Wear Ring

16 Spacer

17 Backup Ring

18 O-ring

19 Setscrew

20 Piston

21 Seal Assembly

22 Guidelock Ring

23 Barrel

24 Reducer

CAUTION

Improper seal installation could cause faulty cylinder

operation.

Item Description

Wiper Ring

Deep Z Seal

Buffer Seal

Retaining Ring

FIGURE 2-46

Backup Ring

Wear Ring

6488-1

CAUTION

Do not scratch the grooved and gland surfaces or

damage the seals and O-rings.

CAUTION

Do not use air pressure to cycle the cylinder. Use only

controlled hydraulic pressure.

FIGURE 2-47

Hydrolock Piston Seals

Guide Lock Ring

Reference Only

Loading...

Loading...