HYDRAULIC SYSTEM TMS800E SERVICE MANUAL

2-88

Published 01-29-2014, Control # 496-00

can be accelerated by pushing the piston/seal

assembly through a honed or polished tube with an

inside diameter equal to the nominal cylinder bore to

plus 0.25 mm (0.010 in).

g. Install the wear ring in the wear ring groove.

3. Place the rod on a clean table.

4. Install the head and then the piston onto the rod noting

the proper orientation of each component. Torque the

piston locknut.

5. Brush piston seals and head seals with hydraulic oil.

6. Install the rod assembly into the barrel. Alignment is

critical. Watch the seals as they pass into the barrel to

ensure that they are not nicked or cut.

7. Slide the head into the barrel and align the retaining ring

drilled hole on the head with the barrel mill slot. Insert

the blunt, curved end of the retaining ring into the hole

and slowly work the head around, using the spanner

wrench until no part of the ring protrudes from the slot.

8. Install the remaining port plugs.

9. Pressurize and cycle the cylinder with hydraulic oil

pressure. Static pressure test the cylinder at 207 bar

(3000 psi) in both directions. Check for proper operation

and any leakage. Make repairs as needed.

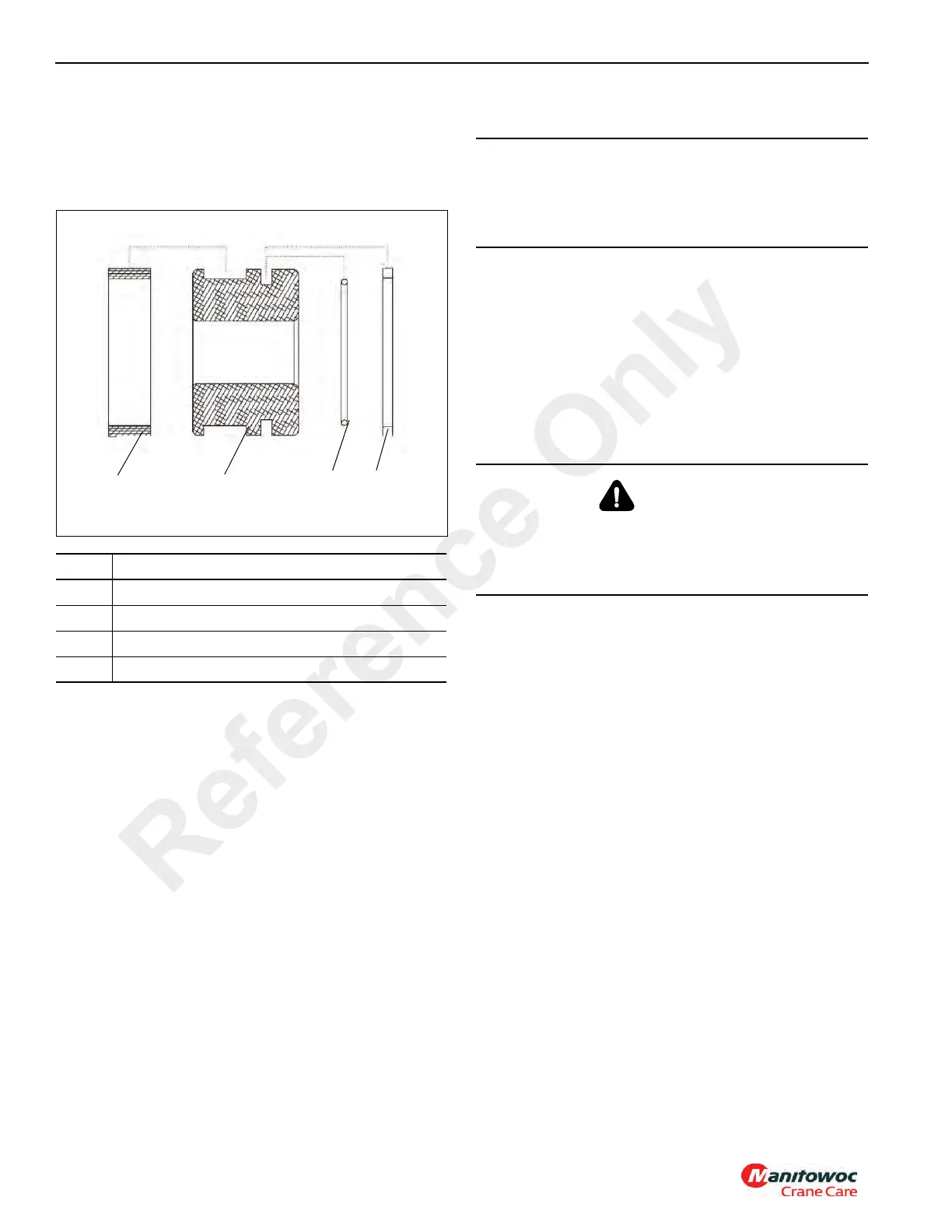

Item Description

1 Wear Ring

2Piston

3 O-ring (Energizer)

4 Piston Seal

CAUTION

Ensure there are no rags or other contaminants left in the

cylinder barrel before installing rod assembly. Lubricate

the barrel inside diameter with hydraulic oil to ease the

rod assembly installation.

WARNING

Before testing, ensure all fittings, hoses, ball valves, and

pump components are rated higher than test pressures.

Do not use air pressure to cycle or pressurize the cylinder.

Failure to do so could result in personal injury or death.

Reference Only

Loading...

Loading...