2-87

TMS800E SERVICE MANUAL HYDRAULIC SYSTEM

Published 01-29-2014, Control # 496-00

Inspection

1. Inspect the rod. There should be no scratches or pits

deep enough to catch the fingernail. Pits that go to the

base metal are unacceptable. Chrome should be

present over the entire surface of the rod. If lack of

chrome on rod, the rod should be replaced.

2. Inspect rod for straightness. Determine if it can be

straightened or must be replaced.

3. Inspect the head. Visually inspect the inside bore for

scratching or polishing. Deep scratches are

unacceptable. Polishing indicates uneven loading, and

the bore should be checked for out-of-roundness.

4. Inspect the piston. Visually inspect the outside surface

for scratches or polishing, Deep scratches are

unacceptable. Polishing indicates uneven loading, and

the diameter should be checked for out-of roundness.

5. Inspect the barrel carefully for scoring, scratches and

pits. There should be no scratches or pits deep enough

to catch the fingernail. If barrel is scored, it must be

repaired or replaced.

6. Thoroughly rinse parts, allow to drain, and wipe with a

lint-free rag. Inspect all parts for serviceability.

Assembly

NOTE: Lubricate head and all seals and rings with clean

hydraulic oil.

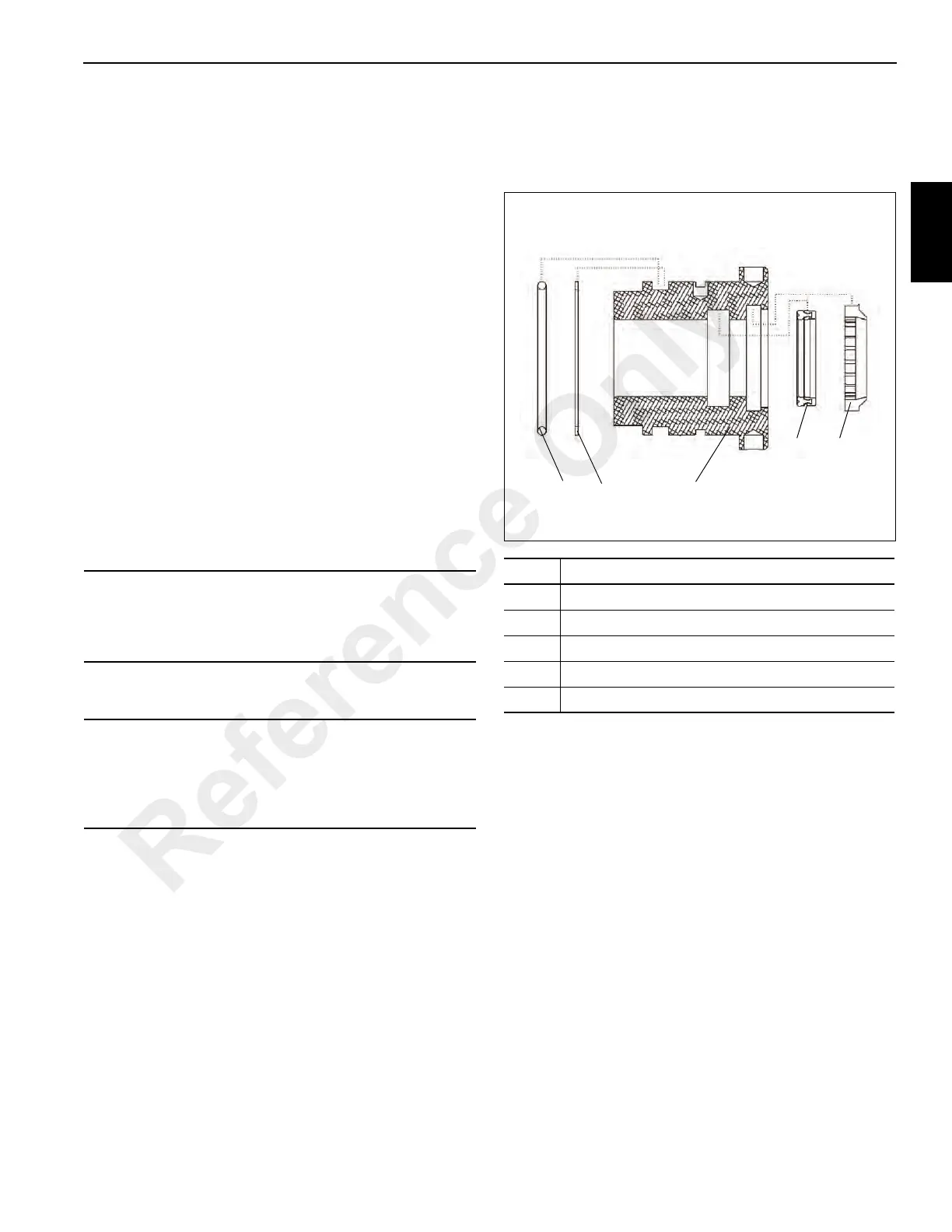

1. Install head seals (see Figure 2-60) as follows:

a. Using round-nose pliers or special installation tools,

twist the dual lip u-cup seal into a “C” shape and

allow it to snap into groove.

b. Using a similar method as in step no. 1, install the

wiper.

c. Install the static O-ring and backup ring into the

static seal groove verifying that the backup ring is

closest to the retaining ring groove.

d. If possible, the head/seal assembly should sit for at

least one hour to allow the seals to elastically

restore.

e. Install wiper ring and seal in the inside of the head.

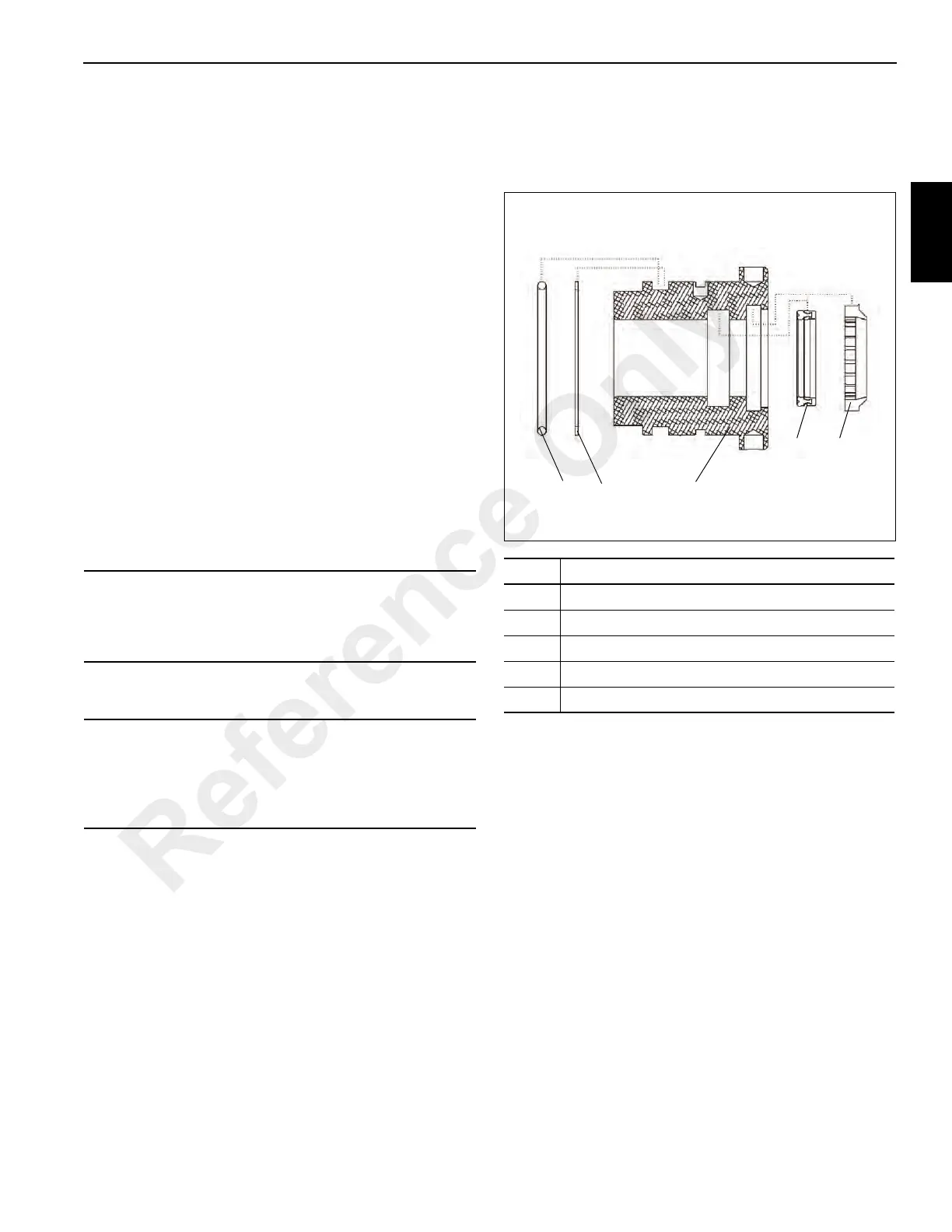

2. Install piston seals (see Figure 2-61) as follows:

a. Separate the two components of the piston seal

assembly (Teflon outer ring and expander).

b. For easiest installation, warm the Teflon outer ring in

49°C to 66°C (120°F to 150°F) hydraulic fluid or

water.

c. Lubricate the piston and all components with

hydraulic fluid.

d. Stretch the inner rubber expander into the seal

groove. Do not use sharp edged tools and verify that

it has not twisted.

e. Stretch the Teflon outer ring into the groove. This

can be done without tools by using a piece of string

or a clean used O-ring to work the Teflon seal

around the piston and into the groove. Be careful

not to damage the seal grooves during installation.

Scratching the groove may cause by-pass leakage.

f. The Teflon ring will have a memory and may take as

long as 24 hours to return to the correct size. This

CAUTION

Before installing new seals and rings, clean all surfaces

and carefully remove burrs and nicks. Parts displaying

excessive wear or damage should be replaced.

CAUTION

When installing new seals and rings, avoid stretching

seals or scratching the grooved or gland surfaces. Make

sure parts are clean before and during assembly. Make

sure seals and rings are installed in the proper order.

Item Description

1 Static O-ring

2 Static Backup Ring

3 Head

4 Rod Seal

5 Rod Wiper

Reference Only

Loading...

Loading...