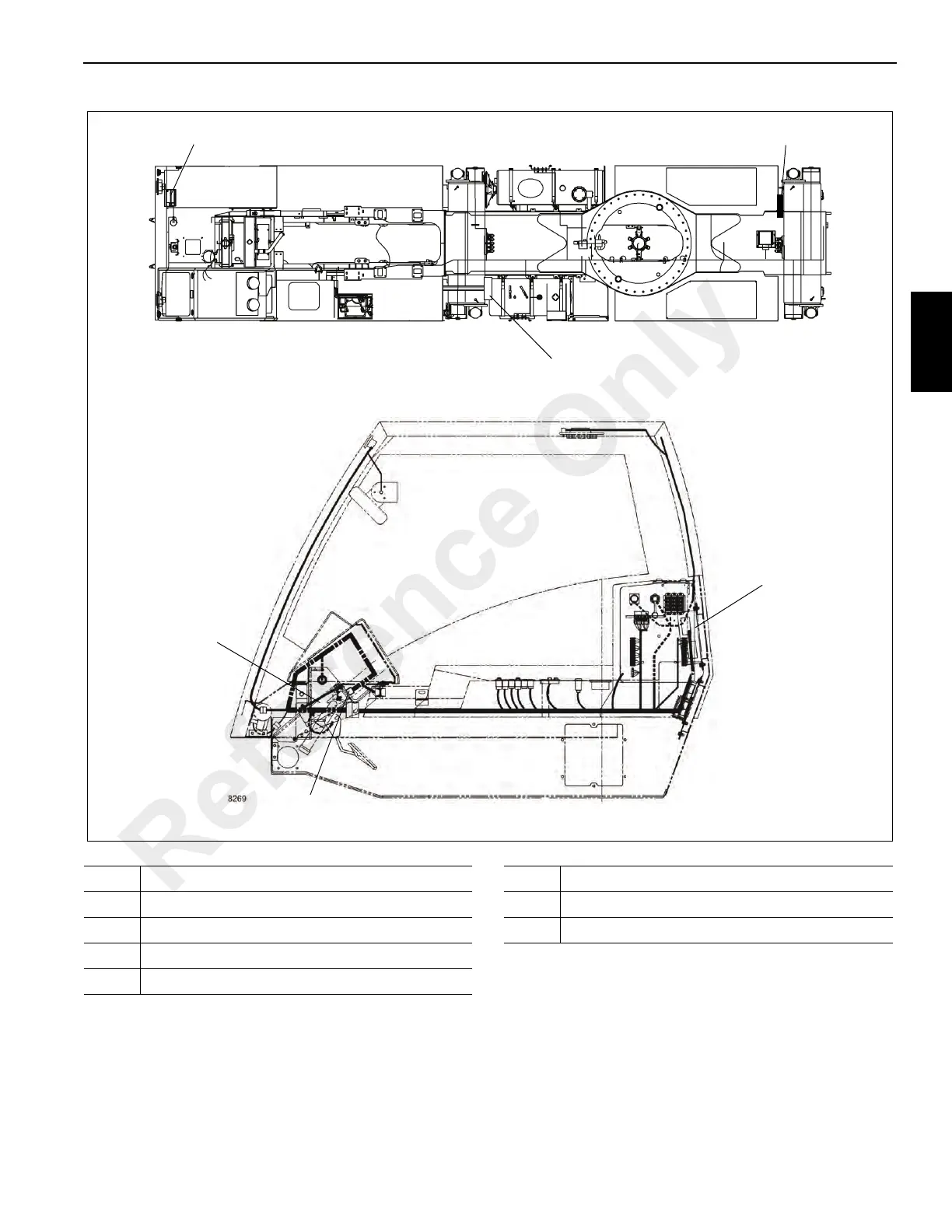

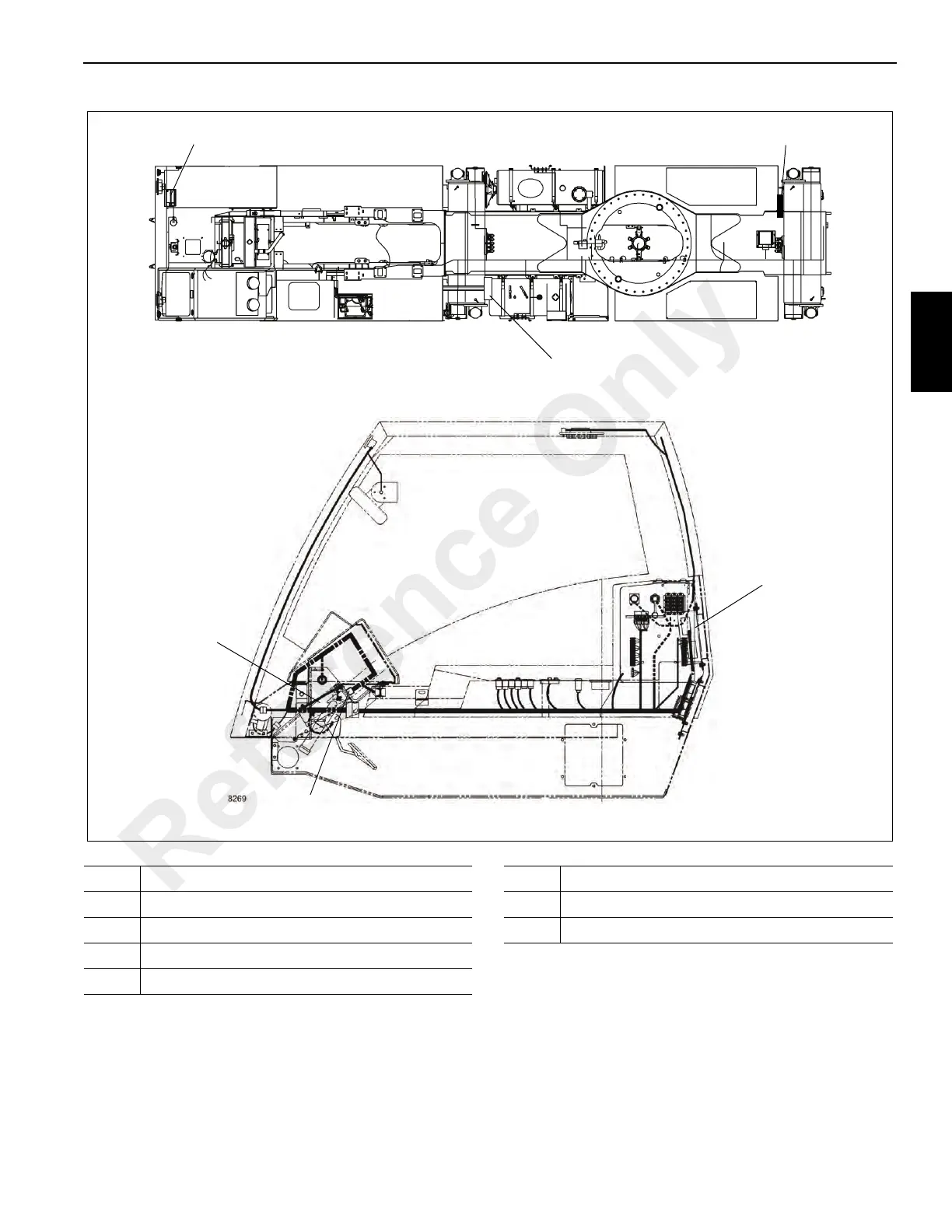

3-3

TMS800E SERVICE MANUAL ELECTRIC SYSTEM

Published 01-29-2014, Control # 496-00

6613-1

3

2

1

4

FIGURE 3-1

Carrier Cab

5

6

Item Description

1 Carrier Frame Center Module

2 Carrier Frame Rear Module

3 Carrier Cab Console Module

4 Master Control Module

Item Description

5 Carrier Frame Front Module

6 Engine Diagnostic Connector

Reference Only

Loading...

Loading...