8-33

TMS800E SERVICE MANUAL UNDERCARRIAGE

Published 01-29-2014, Control # 496-00

4. Adjust the primary and secondary air tank pressures to

6.2 to 6.8 bar (90 to 100 psi).

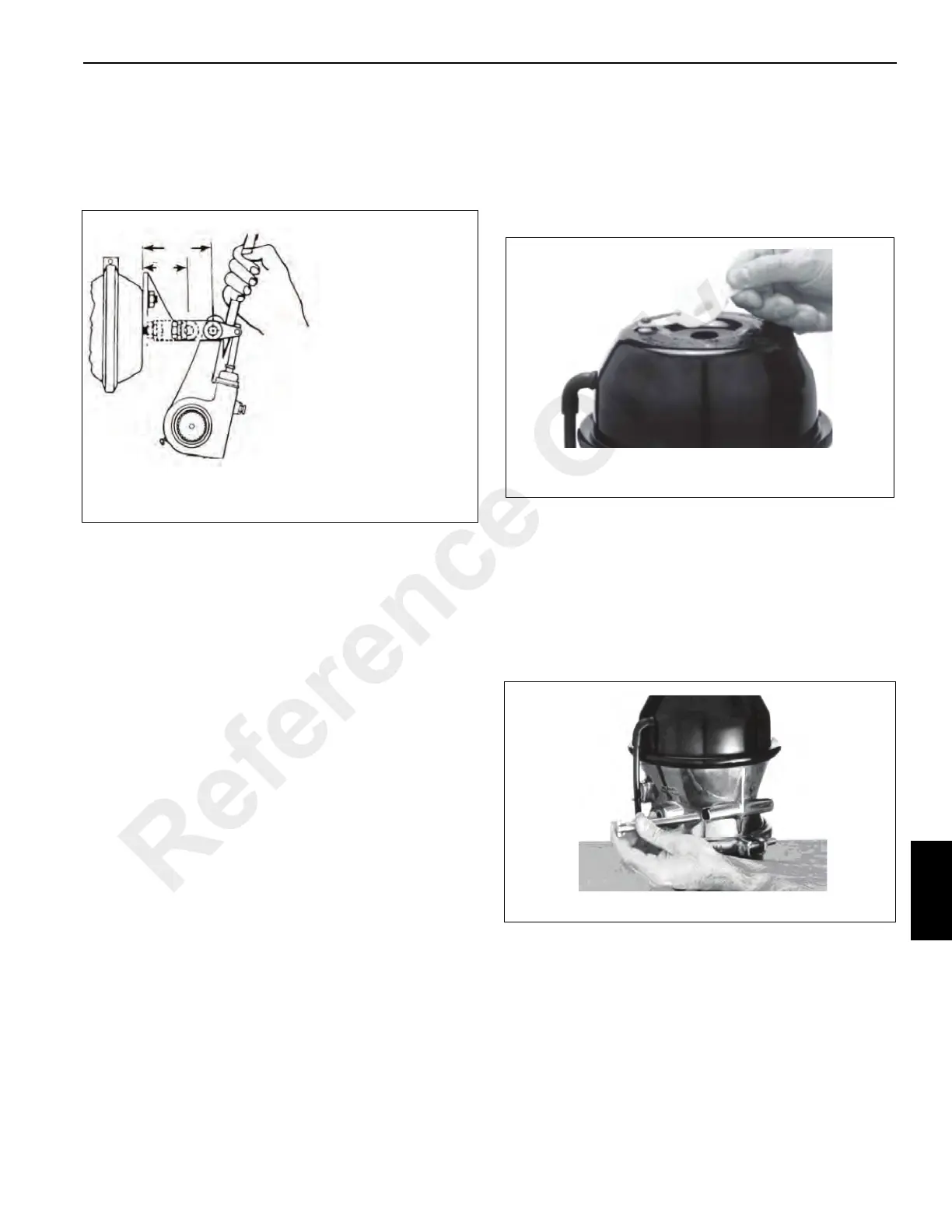

5. With service brakes released, measure distance from

slack adjuster clevis pin to chamber mounting face on

each brake. Refer to Dimension “A” in (Figure 8-36).

6. Starting with 6.2 to 6.8 bar (90 to 100 psi) air tank

pressure in both primary and secondary systems, fully

apply service brakes and hold brakes on. Do not pump

the brakes. Measure between the same points as in step

5 on each brake. This is Dimension “B” in (Figure 8-36).

7. Subtract Dimension “A” from Dimension “B” for each

brake position (Figure 8-36). This value cannot exceed 5

cm (2 in) on the front brakes or 6.3 cm (2.5 in) on the

rear brakes.

8. If any brake exceeds values shown in step 7, the brake

must be re-adjusted per the Brake Free Play

Measurement and Adjustment procedure that follows in

this section.

9. If after adjustment the requirements in step 7 cannot be

met, contact you Manitowoc Crane Care distributor. The

crane cannot be driven on public roads until repaired.

Brake Free Play Measurement and

Adjustment

The following procedure is required to ensure that the free

play of the brakes is within required values.

NOTE: If the brake is equipped with a spring type parking

chamber the spring must be caged before taking

measurements.

1. Chock the wheels and release the parking brakes.

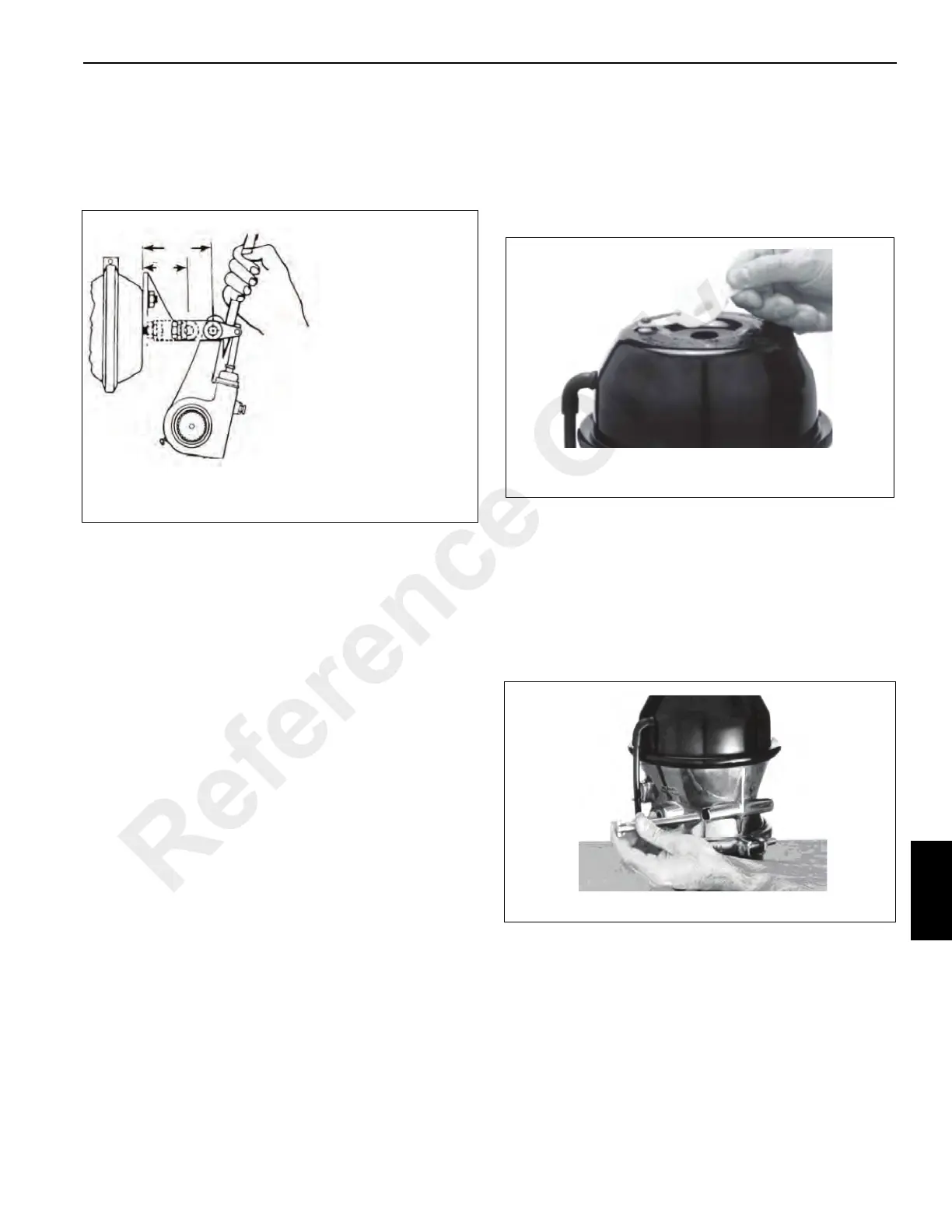

2. Remove the plastic end cap from the spring brake

chamber (Figure 8-37).

NOTE: If the items referred to in step 3 and 4 are not

stored on the chamber, they must be obtained from

the vehicle tool box or Manitowoc Crane Care, as

the piggyback spring brake cannot be manually

released without them.

3. Using a 3/4 inch wrench, unscrew the release-nut and

remove the nut, flatwasher and release-bolt from their

storage pocket on side of chamber (Figure 8-38).

4. Insert the release-bolt into the center hole of the head.

Ensure the formed end of the bolt has entered the hole

in the piston inside the chamber. Continue to insert the

bolt until it bottoms out (Figure 8-39).

FREE STROKE = B MINUS A

Drum brake free stroke must be

12.7 - 15.9 mm (0.5 - 0.625 inches)

7094-2

A

B

MEASURE FREE STROKE

FIGURE 8-36

Reference Only

Loading...

Loading...